6.5.2 Panels with steel surrounds

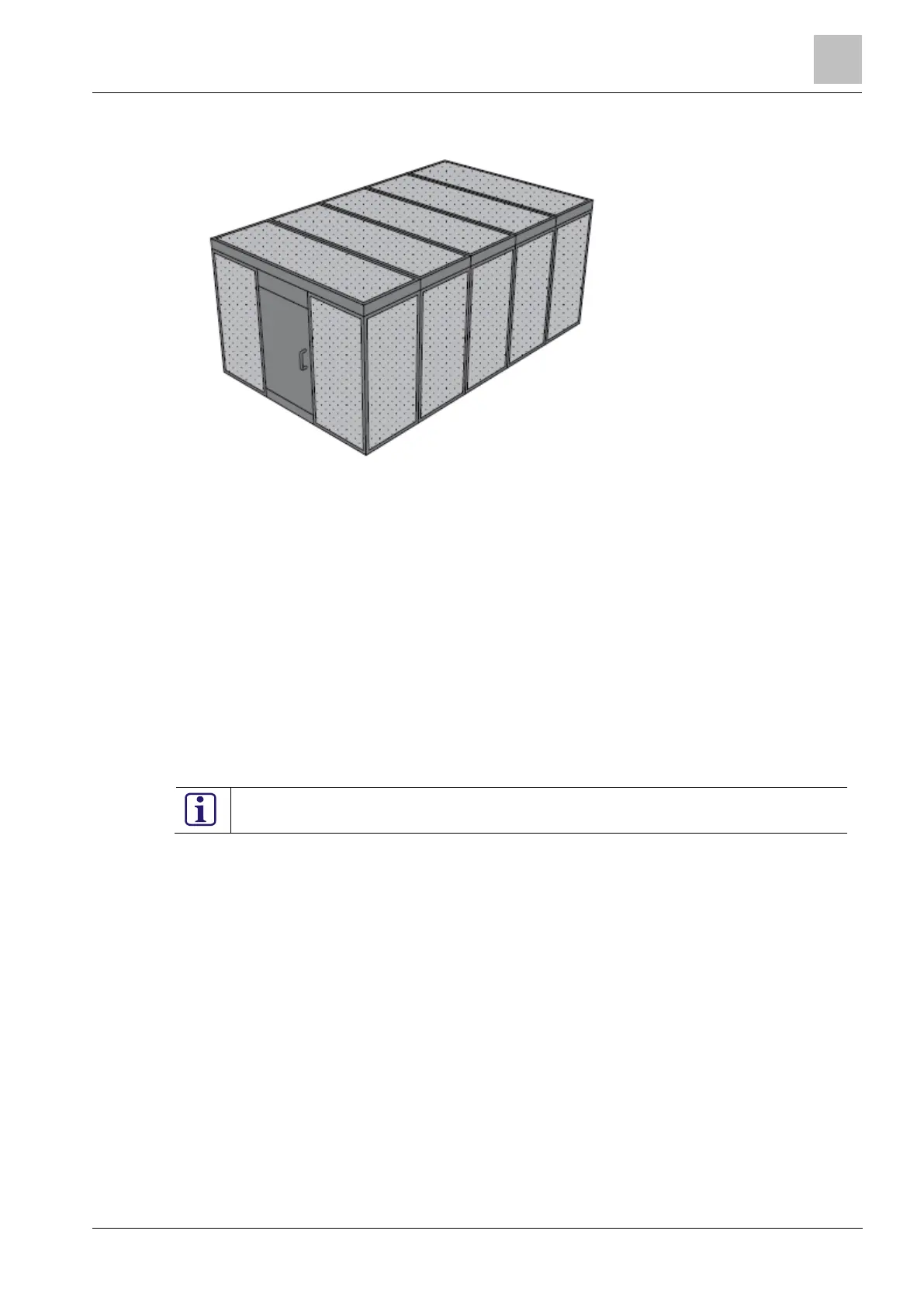

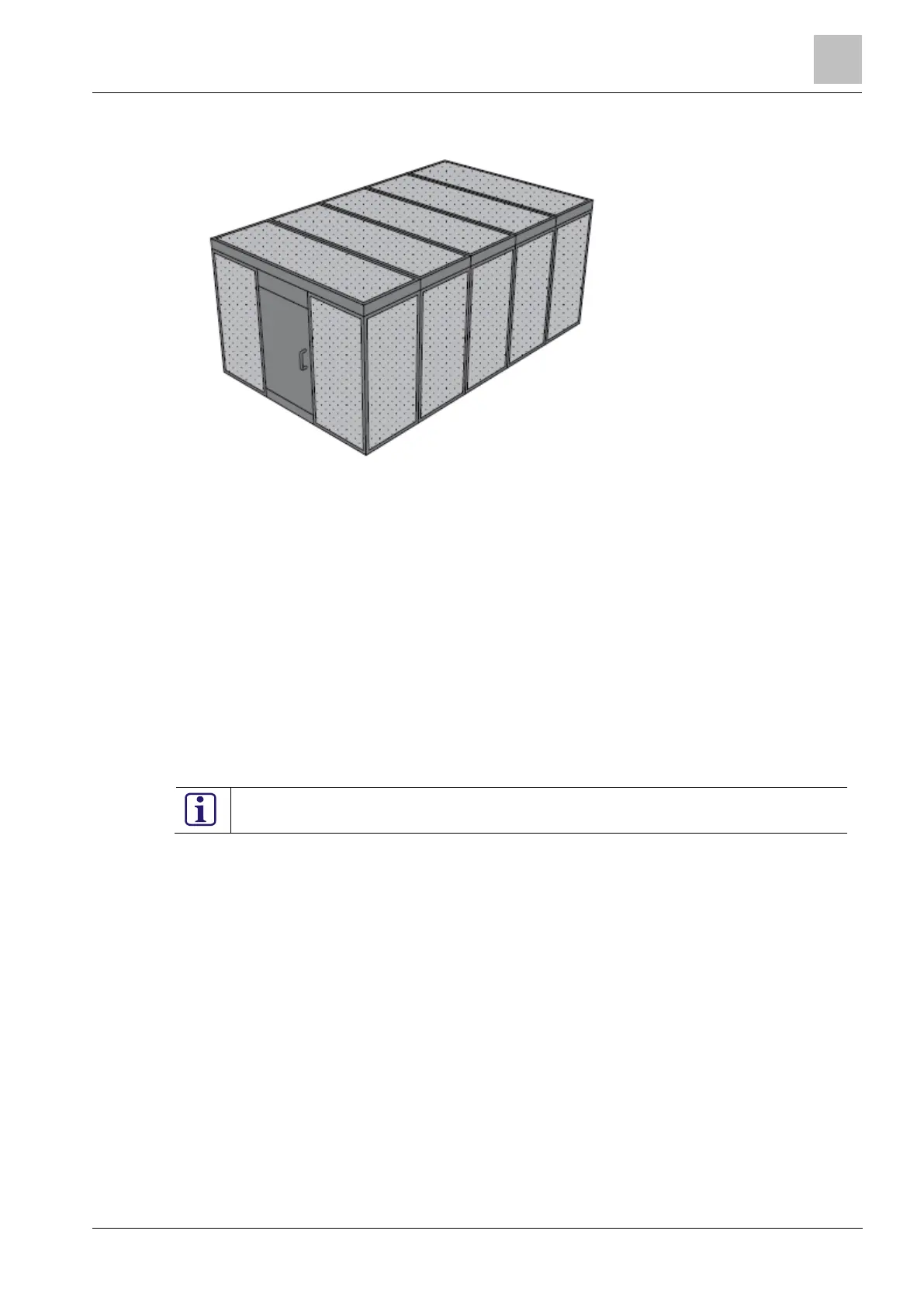

Figure 6-8: Modular vault - panels with steel surrounds

Figure 6-8: Modular vault - panels with steel surrounds shows a vault that is constructed using con-

crete panels with steel surrounds. The steel surrounds may be bolted or welded together to form

the wall.

For signal detection purposes, the interconnection between the steel surrounds will determine the

efficiency of the acoustic transfer. The frequency, size and quality of the joining bolts or welds will

determine the transfer capabilities of the wall. There may be a vast difference in how the panels are

connected together and this will have a direct bearing on the capability of the structure to transfer

the signals that the seismic detectors detect.

In addition to being bolted together, all joints between modules must be welded every 400 −

500mm with a 30 − 40mm seam.

Corner joints between wall modules must be seamlessly welded.

When building vaults using modules of varying thickness, the butt joints must be seamlessly

welded.

Modules which have a pay-in/withdrawal slot must be protected with a detector. This detector will

also be able to monitor the adjacent modules.

As construction methods of vaults may vary, the transfer of operating radius from one

surface to an adjacent surface should not form part of any calculation.

Loading...

Loading...