83

Maintenance: Accessories

Disengageable clutch. Adjusting

Stop the engine and put the clutch lever in neutral.

Remove the inspection hatch and turn the clutch until

the locking device on the adjusting ring is accessible.

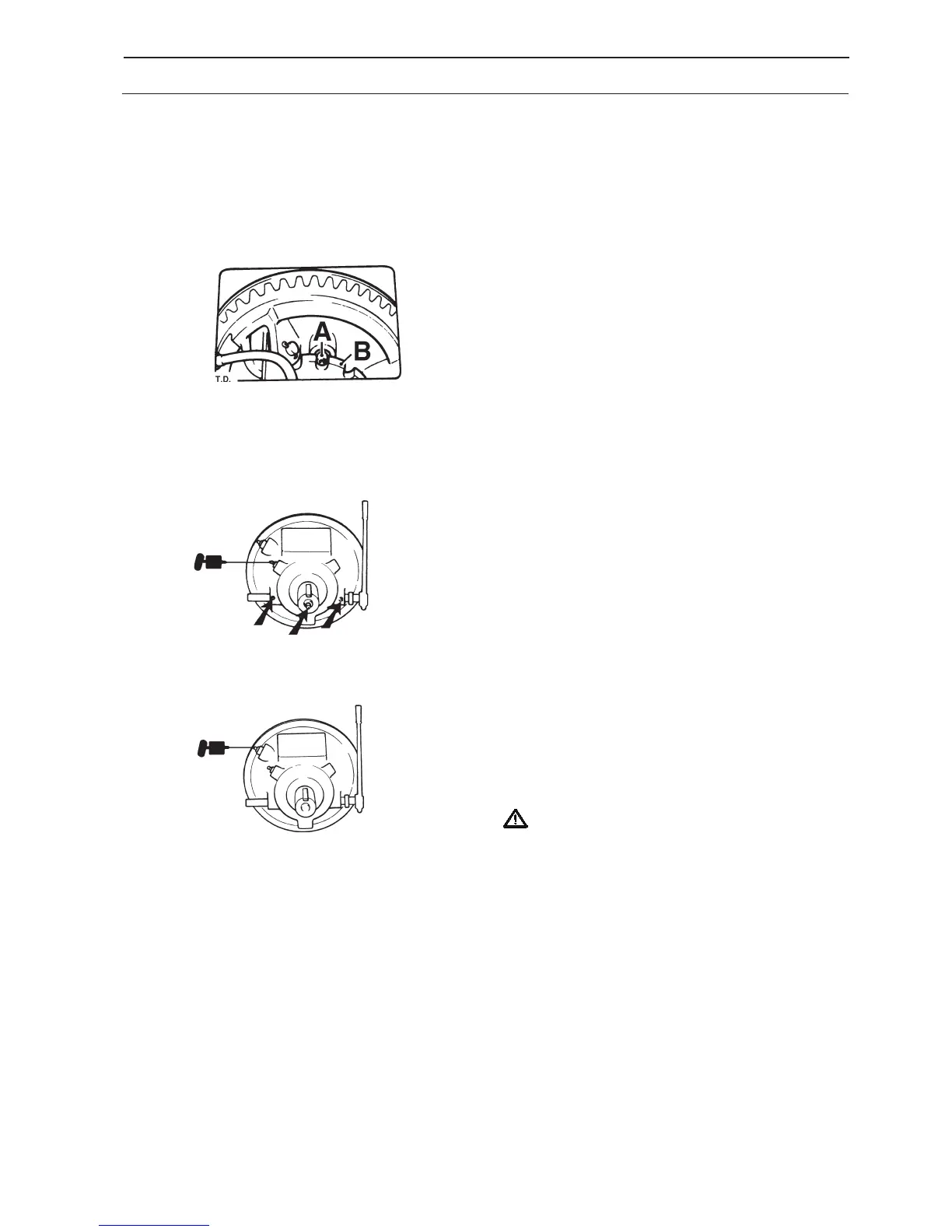

The locking devices have slightly different appearanc-

es depending on the make (see illustrations).

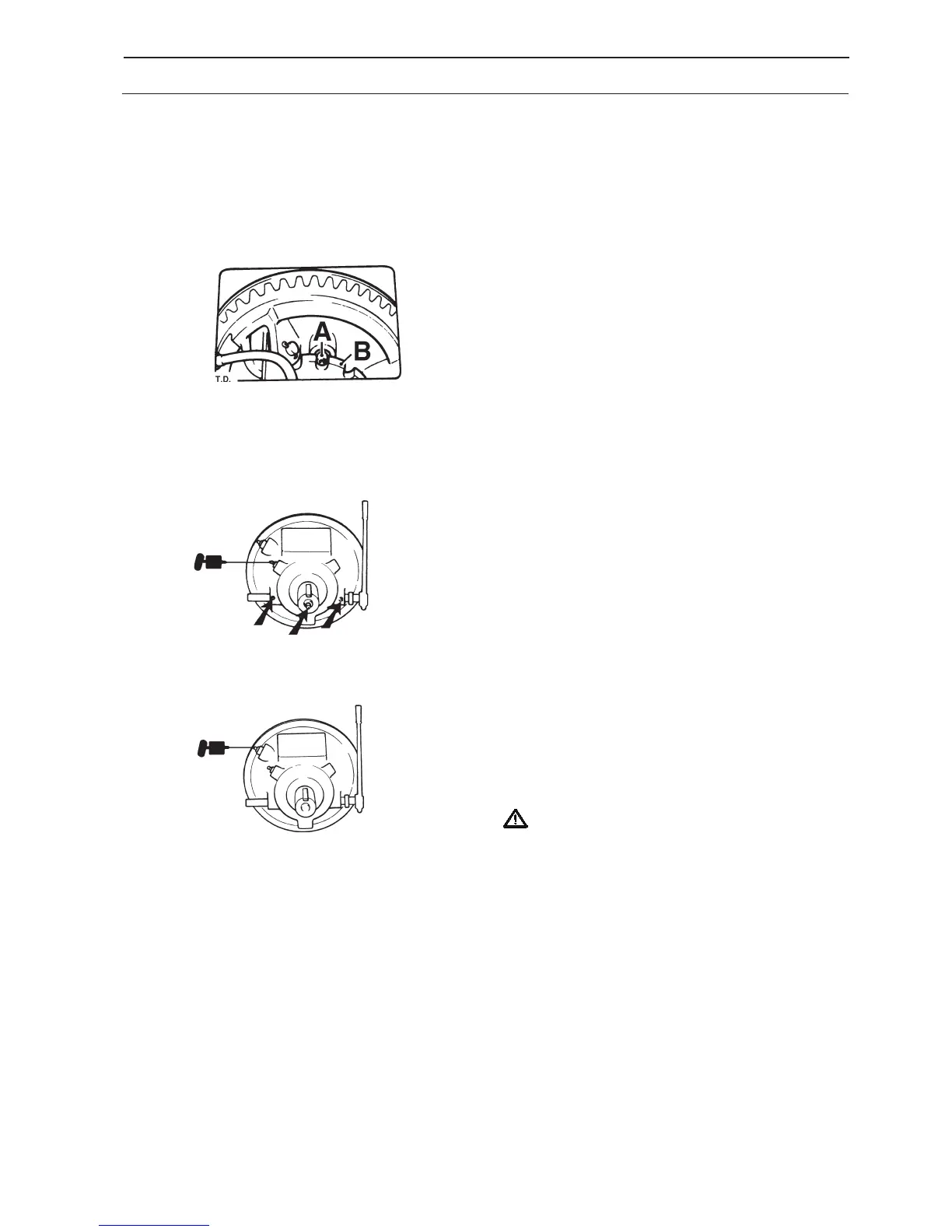

Twin Disc (T.D.)

1. Press the locking pin (A) and turn the adjusting ring

(B) to the right enough notches so that a torque of

218 Nm (161 lbf.ft.) is required on the lever for en-

gagement.

2. Screw on the inspection hatch.

Accessories

Disengageable clutch. Lubrication

Use lithium-based grease such as Mobilux EP2,

Statoil Uniway EP2N, Texaco Multifac EP2, Q8 Rem-

brandt EP2.

Main bearing and clutch mechanism

Lubricate the inner support bearing (with lubricat-

ing nipple), the main bearings, release shaft and the

moving parts in the clutch mechanism with grease.

Lubricate sparingly, 20–30 grams (0.6–1.0 oz ) for

the main bearings.

Lubricate the inner link arms with a few drops of oil.

Release bearing

Lubricate sparingly so the grease is not forced out.

Use grease complying with the recommendations

above.

IMPORTANT! If operated more than 15–20

times a day, the release bearing must be lubri-

cated every 50 operating hours. Otherwise, every

500 operating hours.

Loading...

Loading...