Loading...

Loading...

Do you have a question about the Volvo Penta D12 and is the answer not in the manual?

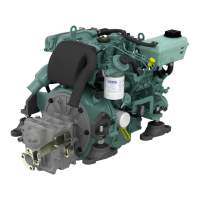

| Displacement | 12.1 liters |

|---|---|

| Bore | 131 mm |

| Stroke | 150 mm |

| Compression Ratio | 17.5:1 |

| Aspiration | Turbocharged and aftercooled |

| Engine Type | Diesel |

| Fuel System | Electronic unit injectors |

| Cooling System | Heat exchanger |

| Type | In-line 6-cylinder |

Provides guidance on safe boat operation, including handling, rules, and checks.

Explains the risk of CO poisoning from exhaust fumes due to low-pressure suction.

Provides essential safety guidance for performing maintenance on the engine.

Addresses risks from fuel, oil, batteries, and starting aids during maintenance work.

Protect hands when checking for leaks; high-pressure fluids can cause severe injury.

Disconnect power before electrical work; protect eyes and skin when handling batteries.

Explains how the single lever controls shift function and engine speed.

Describes the operation of separate levers for shifting and speed control.

Lists essential checks before starting the engine, including fuel, sea cocks, and switches.

Step-by-step guide for starting the engine, including gear neutral, ignition, and warning lamps.

Details starting the engine using the ignition switch or starter button, and overheating protection.

Describes how alarms are indicated and the immediate steps to take, like reducing speed.

Details the standard procedure for stopping the engine using the ignition key.

Lists daily checks including engine general inspection, air filter, oil, coolant, fuel filter, and reverse gear oil.

Emphasizes visual checks for leaks, loose parts, and worn belts, and cleaning procedures.

Instructions on checking the oil level using the dipstick and topping up if necessary.

Details the process for changing engine oil and filters, including warming the engine and checking for leaks.

Provides instructions for mixing coolant with water and safety warnings regarding glycol.

How to check the coolant level via the expansion tank's level glass.

Step-by-step instructions for draining the coolant from the system, including safety warnings.

Details how to top up coolant and fill an empty system, including venting procedures.

Instructions for draining the seawater system to prevent frost damage, with safety warnings.

Covers battery safety hazards (fire, explosion, acid), handling, and cleaning.

Details safety precautions and procedures for charging batteries, including ventilation and cable handling.

Warns against disconnecting main switches while the engine is running to prevent damage.

Instructions for checking and filling the reverse gear oil level at operating temperature.

Steps for changing the reverse gear oil, including sucking out old oil and refilling.

Comprehensive steps for inhibiting the engine for short (max 8 months) and long (more than 8 months) storage.

Steps for preparing the engine after storage, including checks, filter changes, and starting procedures.

Detailed safety precautions and steps for jump-starting the engine using auxiliary batteries.

Describes how to manually shift the revers gear in case of a control lever fault.

Explains the diagnostic function's role in monitoring, detecting, and advising on engine malfunctions.

Describes how malfunctions are displayed via pop-ups and buzzers, and how to acknowledge them.

Table listing symptoms, possible causes, and corresponding fault codes for engine malfunctions.

Explains faults related to the engine speed sensor and the resulting reaction.

Describes faults related to water in fuel filters and the necessary actions.

Covers faults related to high charge air temperature and engine power reduction.

Details faults related to low coolant pressure and the required checks.

Explains faults related to low fuel pressure and engine power reduction.

Details faults for low engine oil level and the resulting engine power reduction.

Covers faults for high engine oil temperature and engine power reduction.

Explains faults for high crankcase pressure and engine power reduction.

Details faults for low transmission oil pressure and engine power reduction.

Explains faults for low battery voltage and necessary checks.

Details faults related to poor primary battery condition or charging.

Covers faults related to a broken EMS supply fuse.

Covers faults related to incorrect lever calibration, preventing helm station selection.

Explains faults related to low seawater pressure and the required checks.

Explains faults for low coolant level and the resulting engine power reduction.

Covers faults for high coolant temperature and the resulting engine power reduction.

Covers faults for high fuel temperature and the resulting engine power reduction.

Explains faults for low engine oil pressure and the resulting engine power reduction.

Details faults related to high oil pressure differential across the filter.

Covers faults for high exhaust temperature and engine power reduction.

Covers faults related to external stop signals and engine stopping/non-starting.

Covers faults related to poor secondary battery condition or charging.

Explains faults when an extra supply fuse is broken.

Explains faults when the 30V supply fuse is broken.

Details faults in the control lever, leading to emergency mode and neutral gear.