Do you have a question about the WAGNER HC 960 and is the answer not in the manual?

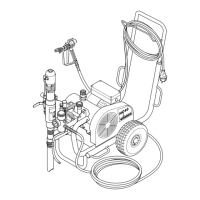

| Brand | WAGNER |

|---|---|

| Model | HC 960 |

| Category | Paint Sprayer |

| Language | English |

Describes high-pressure spray hazards and immediate medical treatment.

Essential points to observe before starting the unit.

Safety rules to follow during breaks or before maintenance.

Covers flash points, explosion protection, and ignition sources.

Details injection injury prevention, gun safety, recoil, and protective measures.

Addresses safe installation, ventilation, earthing, and cleaning precautions.

Instructions and safety for adjusting the pump's position.

Step-by-step guide for swiveling the pump to different positions.

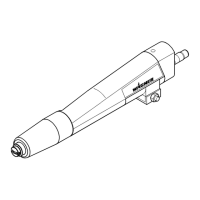

Steps for connecting the high-pressure hose and spray gun.

Steps for filling oil and fuel for gasoline engines.

Procedure for flushing the unit with a cleaning agent before first use.

Steps to prepare and start the unit for spraying.

Steps to safely pause operations, including pressure release.

Detailed steps for cleaning suction and high-pressure filters.

Possible causes and solutions for gasoline engine malfunctions.

Possible causes and solutions for electric motor malfunctions.

Details problems with the hydraulic motor and their remedies.

Addresses issues with insufficient or uneven material ejection.

Covers piston rod movement and low spray gun pressure.

Outlines routine checks and annual service requirements.

Procedures for checking the hydraulic oil level in the tank.

Steps for changing hydraulic oil and filter periodically.

Guidance on visually inspecting the high-pressure hose for damage.