0

Straight V/F curve

1

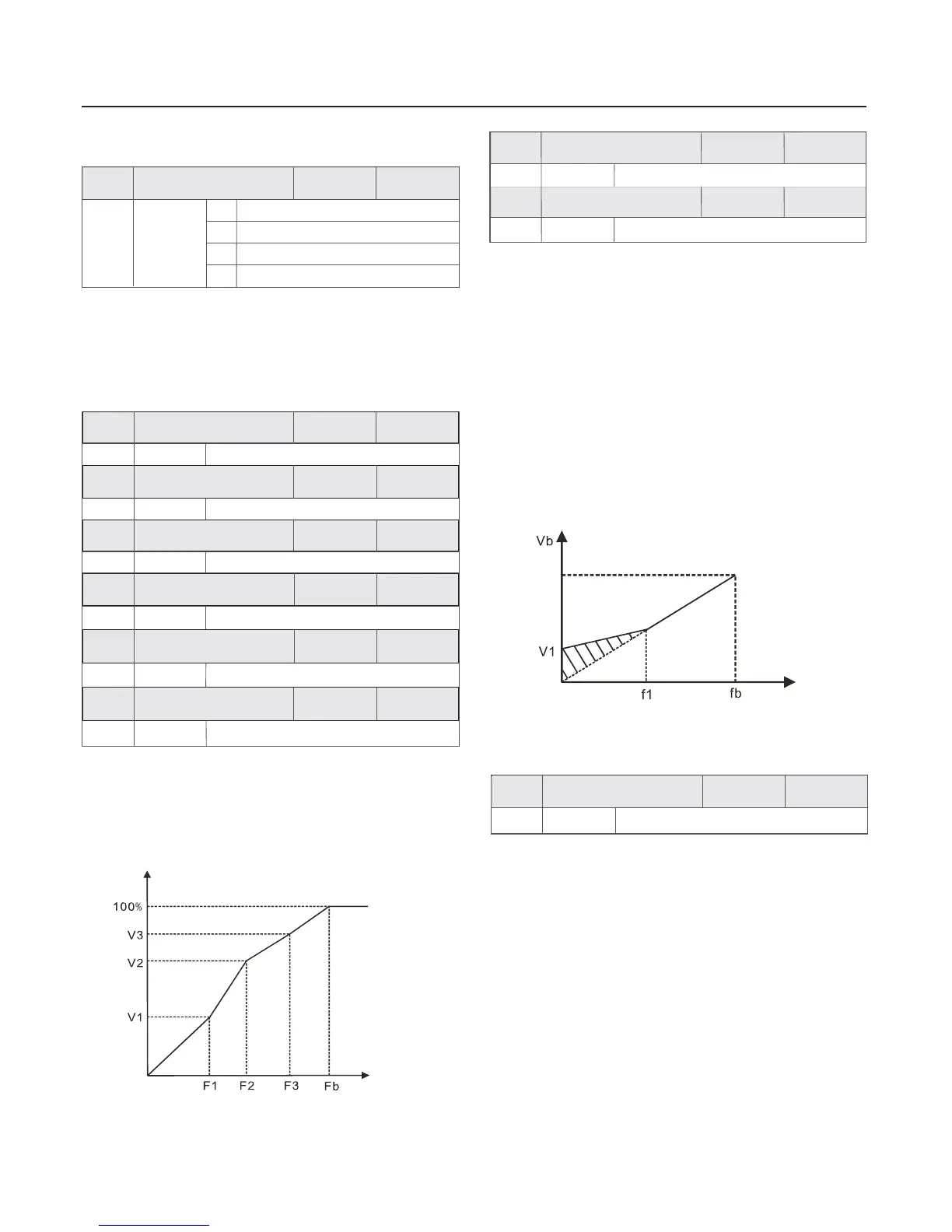

Multiple-point V/F curve

2

Square V/F curve 1 (1.5 time power)

3

Square V/F curve 2 (2.0 time power)

0 Straight V/F curve . It is suitable for common constant torque

load .

:

1 Multiple-point V/F curve . It is suitable for the special loads

such as dehydrator and centrifugal machine .

:

2or3:Square V / F curve 1 or 2 .It is suitabled for the centrifugal

loads such as fan and pump .

。

V1 V3~

V2 100.0~%

There are six parameters F2.01 to F2.06 to define MS V/F curve .

The setup value of V/F curve is generally set in accordance

with the load characteristics of the motor .

Note In case of low frequency , higher setup voltage may

cause over heat and even burning of the motor ,

stall over current or current protection.

:

the inverter

is likely to encounter

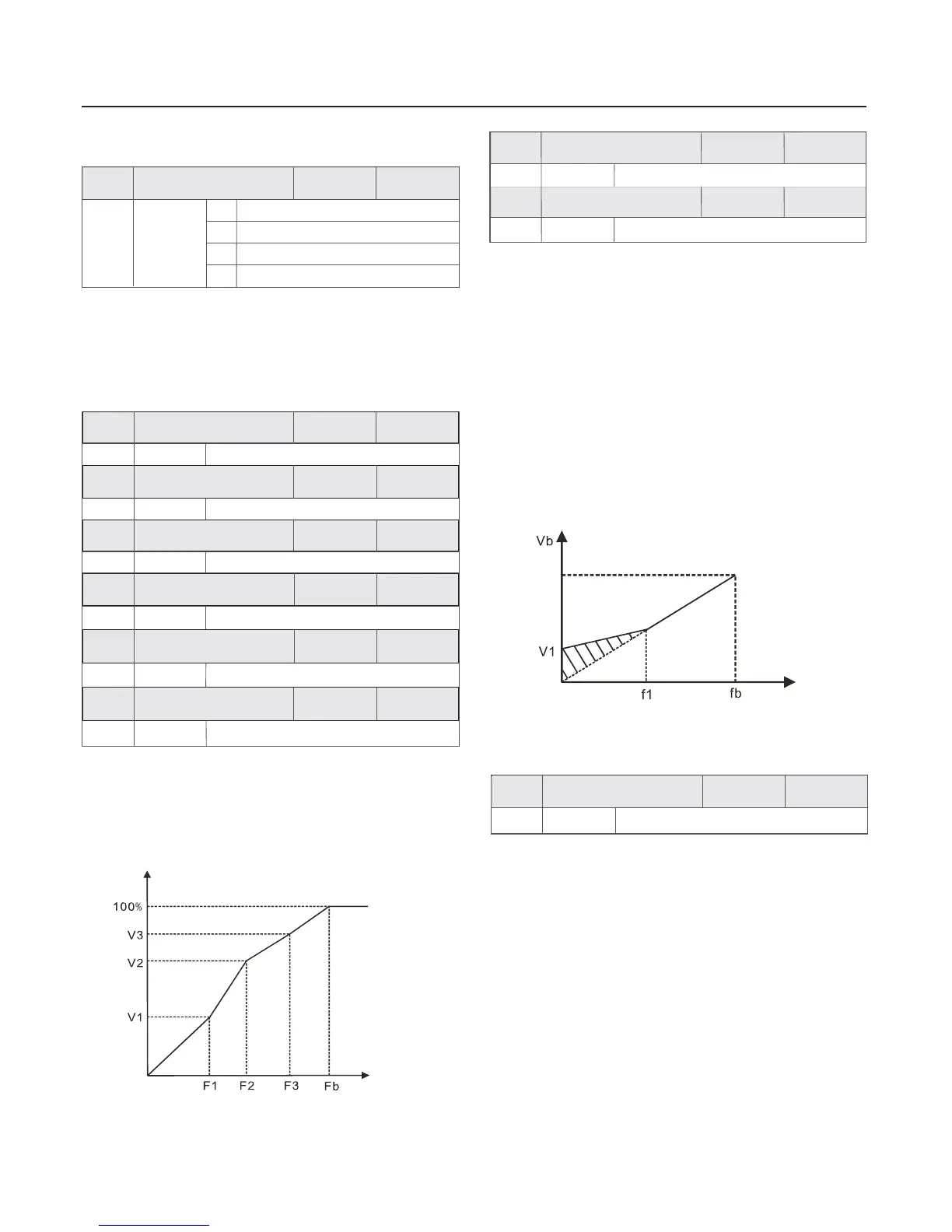

To compensate the low frequency torque characteristics of

V/F control , it can boost the output voltage of the inverter at

the time of low frequency .

If the torque boost is set to be too large , the motor may be over

heat , and the inverter may be over current .

Adjust this parameter effectively can avoid over current upon

startup . For the relatively large loads , it is recommended to

increase this parameter . For the small loads , this parameter

value could be reduced .

Cutoff frequency of torque boost: Under this frequency , the

torque boost is enabled . If it exceeds this setup frequency ,

the torque boost is disabled .Refer to figure for details .

Group F2

V/F Control Parameters

Setup range

Setup range

Setup range

Setup range

Setup range

Setup range

Setup range

F2~

Motor rated frequency

0.

0Hz

~

F2

0. 0%~

V2

~

F1

F3

It is active only for V/F control . Set this parameter can

compensate the slip in the V/F control mode due to load

and reduce the of the motor

with the variety of the load . In general ,

100% corresponds to the rated slip of the motor with rated

load . Slip coefficient adjustment can refer to the following

principles: When the load is rated load and the slip

compensation coefficient is set to 100% , the velocity

of the motor in the inverter is close to the reference velocity .

variation rotation velocity

which is change

rotation

If the actual rotation velocity is lower than the reference

velocity ,the coefficient should be increased accordingly and

vice versa .

46

F2.00

V/F curse setup

0

F2.01

V/F frequency point F1

0. 00Hz

F2.02

V/F voltage point V1

0. 0%

F2.03

V/F frequency point F2

F2.04

V/F voltage point V2

F2.05

V/F frequency point F3

F2.06

V/F voltage point V3

25.00Hz

50.00Hz

50.0%

100.0%

When the torque boost is set to 0% , the inverter will adopt

automatic torque boost .

Chapter 6 Parameter Description

Factory

default value

Factory

default value

Setup range

Setup range

0.0

0.0

20.0%

Hz~

~

rated frequency

50.00Hz

F2.07

Torque boost

F2.08

Cutoff frequency of

torque boost

Model

dependent

Factory

default value

Factory

default value

Factory

default value

Factory

default value

Factory

default value

Factory

default value

Factory

default value

0~

200%

Setup range

F2.09

Slip compensation

coefficient

0%

Factory

default value

Voltage%

Frequency Hz

V1-V3:

F1-F3:

Fb:

Segments 1 to 3 Voltage Proportion MS V/F

Segments 1 to 3 Frequency Point of MS V/F

Rated Motor Frequency F1.04

Fig .6-2 Schematic Diagram for V/F Curve Setup

Output voltage

Output frequency

V1 Manual Torque Boost Voltage

f 1 Cutoff Frequency of Torque Boost

:

:

Vb Rated Output Voltage

f b Rated Frequency

:

:

Fig .6-3 Schematic Diagram for Manual Torque Boost

Loading...

Loading...