VESDA PipeNetwork Design Guide VESDA by Xtralis

32 www.xtralis.com

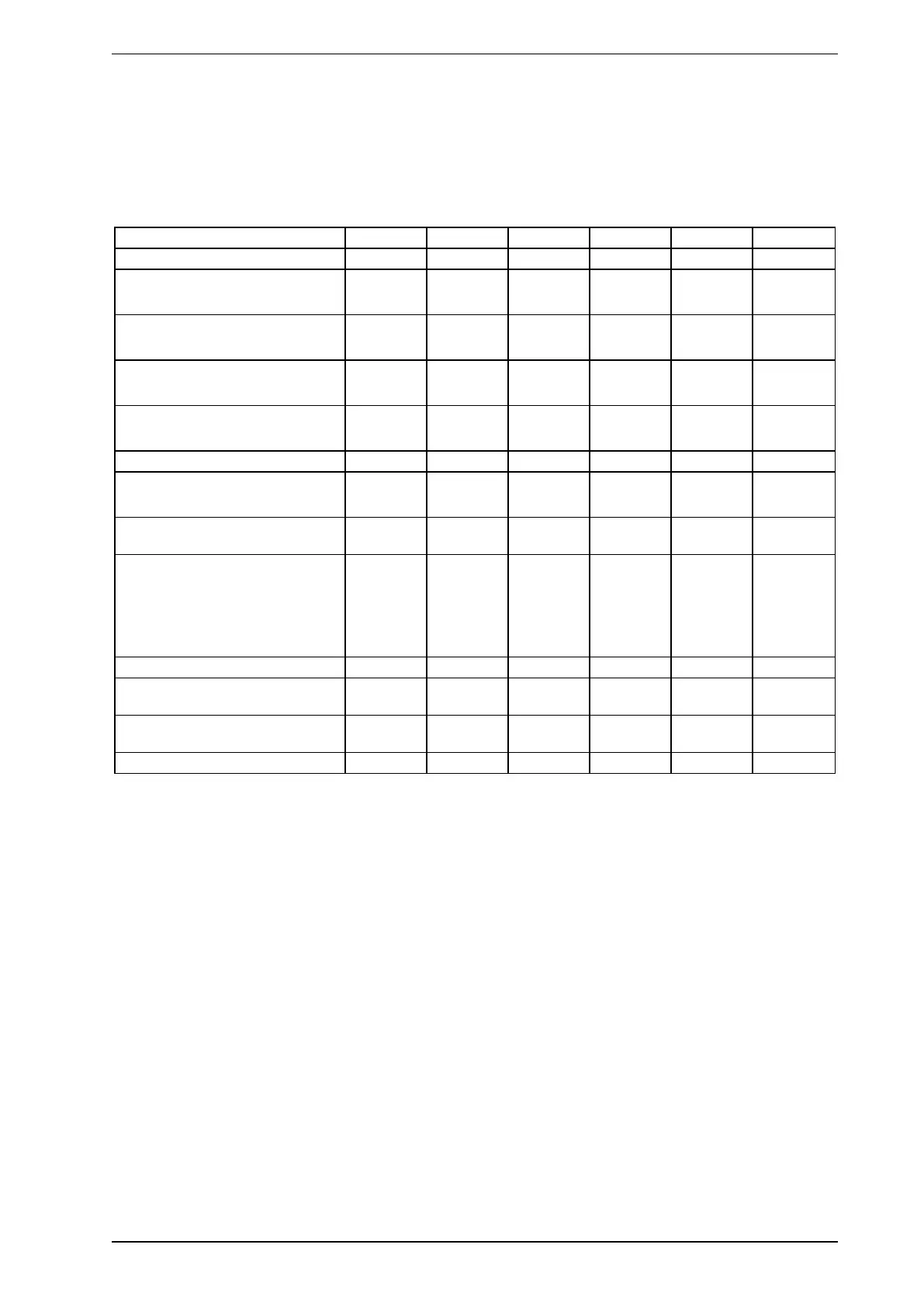

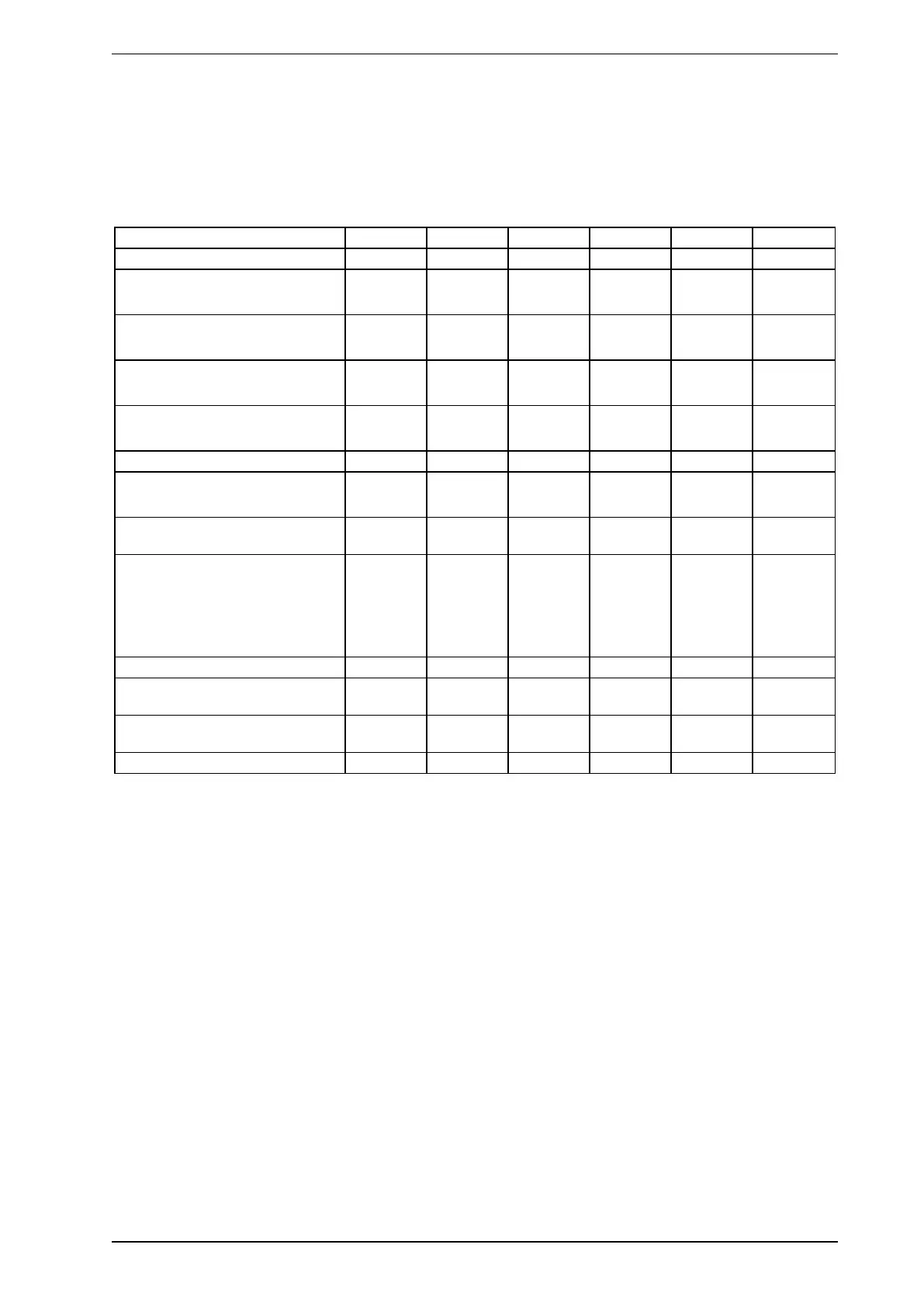

6.2 Detector Parameters

Different detectors in the VESDA range have different characteristics. The pipe network design parameters

for each of these detectors may vary according to site conditions and requirements. The parameters for

VESDA detectors are given below.

Parameters VLF-250 VLF-500 VESDA VLC VESDA VLP VESDA VLS VESDA VLI

ASPIRE2 support Yes Yes Yes Yes Yes Yes

Maximum area covered 250 m²

(2,500 sq.ft)

500 m²

(5,000 sq.ft)

800 m²

(8,000 sq.ft)

2,000 m²

(21,500 sq.ft)

2,000 m²

(21,500 sq.ft)

2,000 m²

(21,500 sq.ft)

Maximum number of Pipes 1

(2 branches)

1

(2 branches)

1

(2 branches)

4

(8 branches)

4

(8 branches)

4

(8 branches)

Maximum aggregate length 25 m

(80 ft)

50m

(150ft)

80 m

(260 ft)

200 m

(650 ft)

200 m

(650 ft)

360 m

(1,200 ft)

Maximum length for each pipe N/A N/A N/A 100 m

(325 ft)

100 m

(325 ft)

90 m

(300 ft)

Maximum branch length 15 m (50 ft) 30m (90ft) 50 m (164 ft) N/A N/A N/A

Maximum sampling holes per pipe

(including end cap hole)

12 24 20 25 25 16

Maximum sampling holes per branch

(including end cap hole)

6 12 20 Aggregate

max 25

Aggregate

max 25

Aggregate

max 16

Maximum length of capillaries 4 m (13 ft) for

small bore

(5.2 mm)

tube and 8 m

(26 ft) drop

pipes.

4 m (13 ft) for

small bore

(5.2 mm)

tube and 8 m

(26 ft) drop

pipes.

4 m (13 ft) for

small bore

(5.2 mm)

tube and 8 m

(26 ft) drop

pipes.

4 m (13 ft) for

small bore

(5.2 mm)

tube and 8 m

(26 ft) drop

pipes.

4 m (13 ft) for

small bore

(5.2 mm)

tube and 8 m

(26 ft) drop

pipes.

4 m (13 ft) for

small bore

(5.2 mm) tube

and 8 m (26

ft) drop pipes.

Aspirator speed: Fixed Fixed Fixed Variable Variable Variable

Minimum system air flow 12

liters/minute

12

liters/minute

20

liters/minute

20

liters/minute

20

liters/minute

40

liters/minute

Minimum air flow per pipe N/A N/A N/A 15

liters/minute

15

liters/minute

20

liters/minute

Minimum sector pressure 65 Pa 65 Pa 70 Pa 70 Pa 70 Pa 70 Pa

Table 6-1: VESDA detector parameters

The parameters given above are for a typical pipe network. Site conditions and requirements will dictate the

final parameters for each site. The aggregate pipe length can exceed the published values, provided the

minimum pressure at each sampling point is at least 25 pascals. It is recommended that transport time for the

network is maintained at 60 seconds or less and hole balance and hole share be at least 70% (use ASPIRE2

to calculate these values). These values may be relaxed subject to local fire codes and conditions. Exceeding

the guidelines listed in this manual is allowable if the ASPIRE2 software approves the design.

These pipe lengths represent best practice for systems with single pipe runs on each port (no branching).

Longer and/or more complex pipe arrangements are also possible and must be verified using ASPIRE2 to

ensure transport time and system balance requirements are met.

Loading...

Loading...