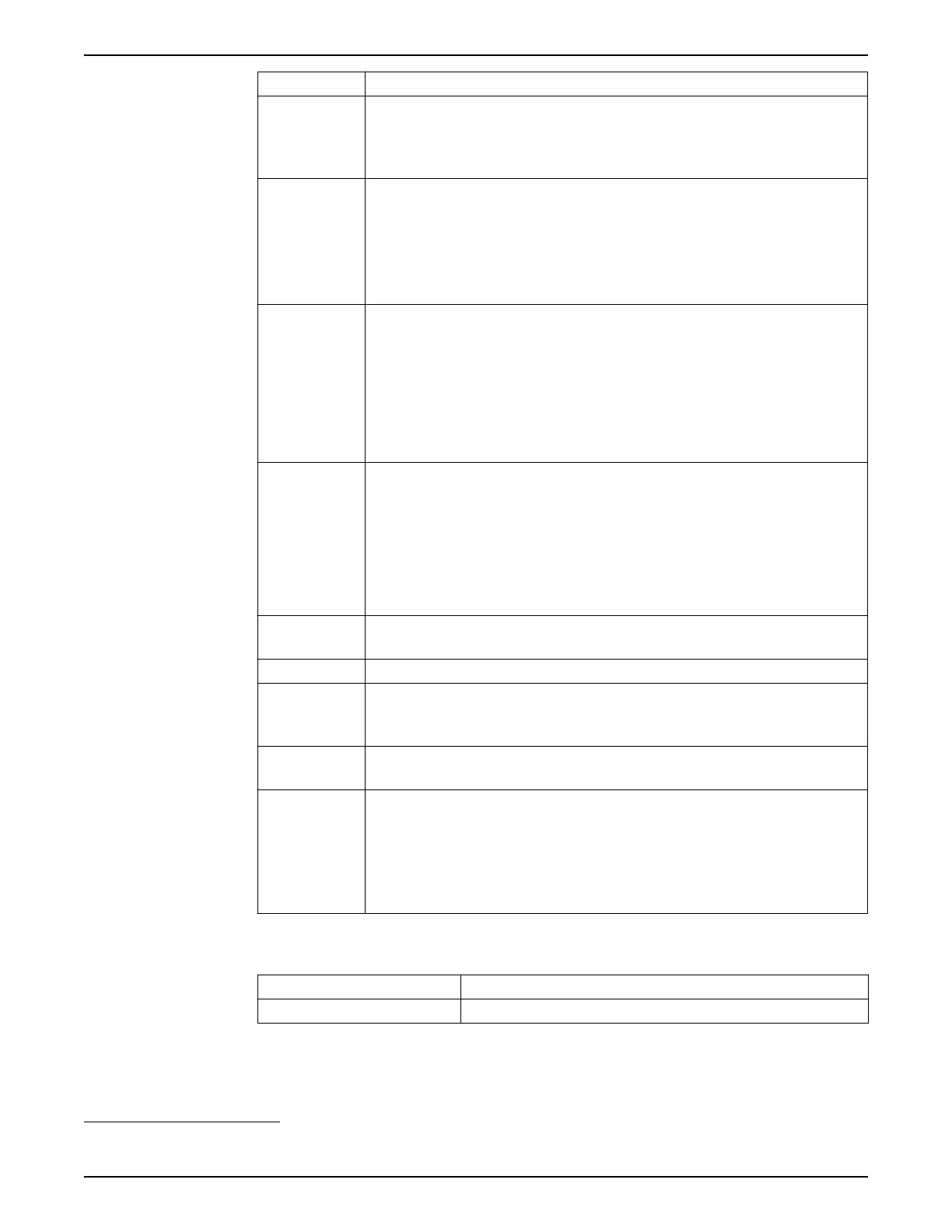

Service item Action

Impeller 1. Check for worn or damaged parts.

2. Adjust and/or replace if necessary.

Wear on the impeller or surrounding parts necessitates fine adjustments of the impeller or

replacement of worn parts.

Oil Check the oil:

1. Take an oil sample.

2. If the oil contains particles, then replace the mechanical seal. Contact an authorized

service shop.

Make sure that the volume is filled to the correct level.

A smaller amount of water is not harmful for the mechanical seal.

Cable entry 1. Check that the following requirements are met:

• The cable clamps must be properly tightened.

• The cable entry must be firmly tightened into its bottom-most position.

• The seal sleeve and the washers must conform to the outside diameter of the

cables.

2. Cut off a piece of the cable so that the seal sleeve closes around a new position on the

cable.

3. Replace the seal sleeve, if necessary.

Inspection

volume

1

1. Check that the inspection screw is properly tightened.

2. Remove the inspection screw.

3. Drain all liquid, if any.

4. If there is oil in the inspection volume, then empty the oil and check again after one

week. If there is oil in the inspection volume again, then replace the mechanical seal.

Contact an authorized service shop.

5. If there is water in the inspection volume, then check that the inspection screw O-ring

is not damaged.

Cable 1. If the outer jacket is damaged, replace the cable.

2. Check that the cables do not have any sharp bends and are not pinched.

Cooling system If the flow through the system has been partly restricted, then rinse and clean.

Level sensors or

other sensor

equipment

1. Check the functionality.

2. Repair or replace any damaged equipment.

3. Clean and adjust the equipment.

Starter equipment 1. Check the condition and functionality.

2. Contact an electrician, if necessary.

Insulation

resistance in the

stator

1. Check the insulation between:

• Phase–phase on the stator

• Phase–ground (earth)

The insulation should be > 1 megaohm. Use a 1000-VDC megger to test the

insulation.

2. If the resulting value is < 1 megaohm, then contact an authorized service shop.

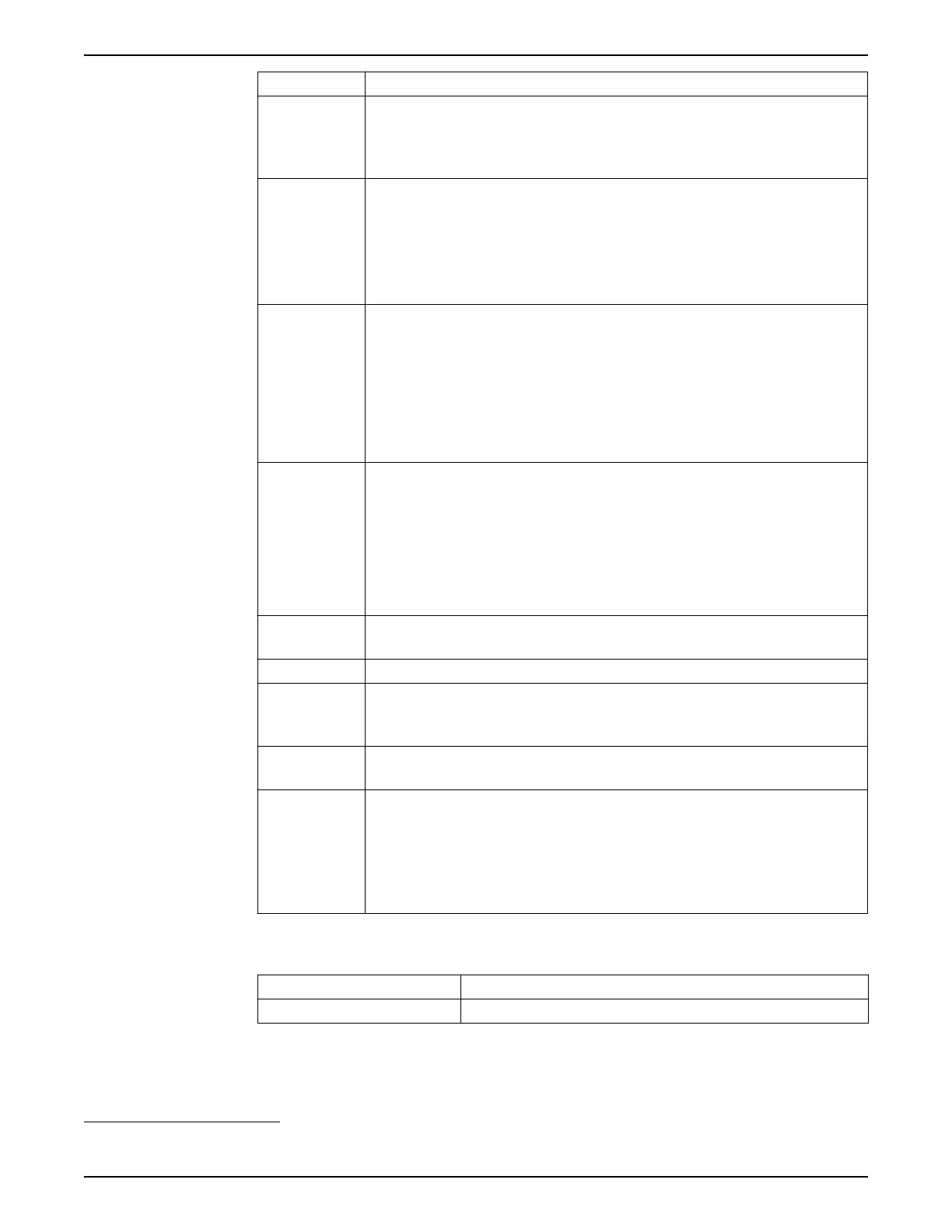

6.2.2 Major overhaul

For a major overhaul, do the following in addition to the tasks listed under Inspection.

Service item Action

Support and main bearing Replace the bearings with new bearings.

1

Regardless of individual applications, the inspection volume should not be inspected less frequently than the intervals for normal applications and

operating conditions at media (liquid) temperatures <40°C (104°F).

6 Maintenance

32 Flygt 2190, 2201 Installation, Operation, and Maintenance Manual

Loading...

Loading...