6.4.7 Install the impeller, alternative 3

Table 9: Applicability

Product code Pressure class Open or closed impeller

2201.012 SH Closed

1. Prepare the shaft:

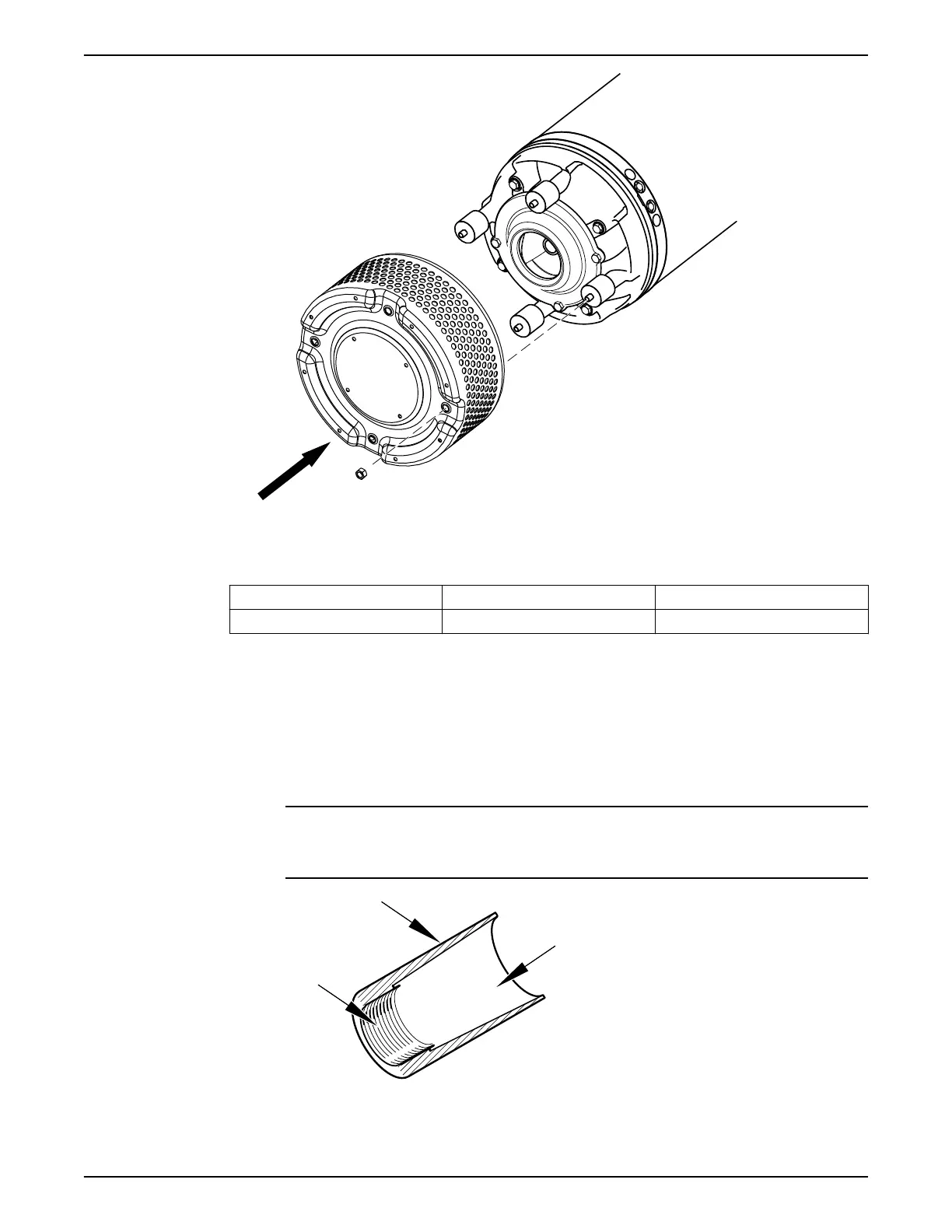

a) Polish off any flaws with a fine emery cloth.

The end of the shaft must be clean and free from burrs.

b) Coat the inner conic, the outer cylindrical surfaces, and the thread of the conical

sleeve with a thin layer of grease.

The proper lubrication is grease for bearings, for example Exxon Mobil Unirex N3,

Mobil Mobilith SHC 220 or equivalent.

NOTICE:

Surplus grease can cause the impeller to become loose. Remove surplus grease

from conical and/or cylindrical surfaces of shafts and/or sleeves.

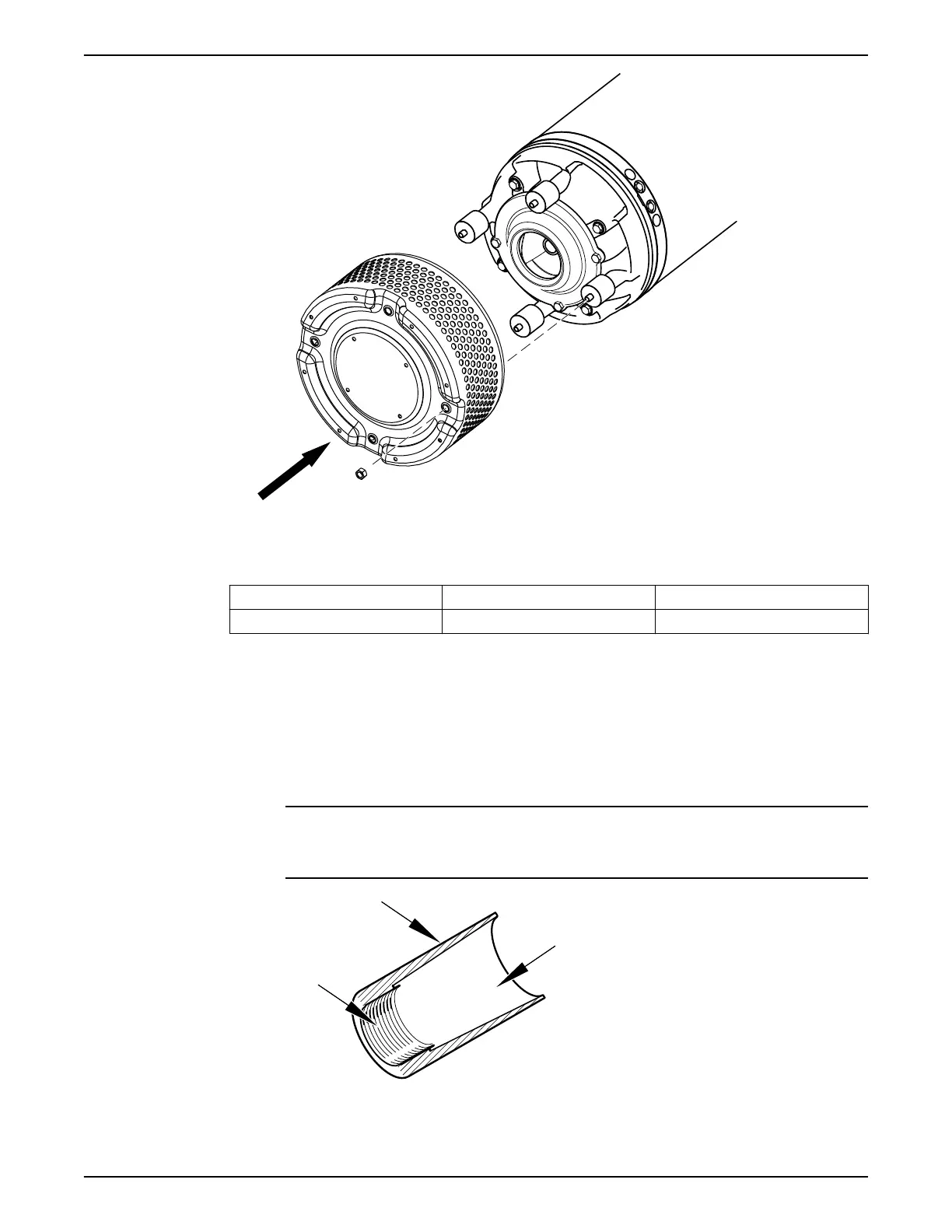

2. Align the edge of the upper adjustment screw with the edge of the upper conical

sleeve so that they are flush.

6 Maintenance

Flygt 2190, 2201 Installation, Operation, and Maintenance Manual 45

Loading...

Loading...