102777-YIM-E-0206

Unitary Products Group 15

POWER AND CONTROL WIRING

Field wiring to the unit must conform to provisions of National

Electrical Code (NEC) ANSI / NFPA 70-Latest Edition and / or

local ordinances. The unit must be electrically grounded in

accordance with the NEC and / or local codes. Voltage toler-

ances which must be maintained at the compressor terminals

during starting and running conditions are indicated on the

unit Rating Plate and Table 1.

The internal wiring harnesses furnished with this unit are an

integral part of the design certified unit. Field alteration to

comply with electrical codes should not be required. If any of

the wire supplied with the unit must be replaced, replacement

wire must be of the type shown on the wiring diagram and the

same minimum gauge as the replaced wire.

Power supply to the unit must be NEC Class 1 and must

comply with all applicable codes. A disconnect switch must

be provided (factory option available). The switch must be

separate from all other circuits. Wire entry at knockout open-

ings requires conduit fittings to comply with NEC and/or Local

Codes. Refer to Figures 13, 14, 15, and 16 for installation

location of openings.

If installing a field mounted disconnect on the unit, refer to

Figure 17 for the recommended mounting location. Unit-

strutTM or equivalent rails should be mounted as shown to

provide structure for mounting. The location of the rails

should be adjusted to fit the disconnect within the dimensions

shown. Conduit run from the disconnect to the power entry

location in the baserail should be routed so that it does not

interfere with the doors of the unit access panels.

NOTE: Since not all local codes allow the mounting of a dis-

connect on the unit, please confirm compliance with

local code before mounting a disconnect on the unit.

Electrical wiring must be sized properly to carry the load.

Each unit must be wired with a separate branch circuit fed

directly from the meter panel and properly fused.

Refer to Figure 5 for typical field wiring and to the appropriate

unit wiring diagram mounted inside control doors for control

circuit and power wiring information.

POWER WIRING DETAIL

Units are factory wired for the voltage shown on the unit

nameplate. The main power block requires copper wires.

Refer to Electrical Data Tables 13 through 24 to size power

wiring, fuses and disconnect switch. All field supplied wiring,

fuses and disconnects must comply with applicable NEC

codes.

Power wiring is brought into the unit through the side of the

baserail or the bottom of the unit/control box inside the curb.

The baserail has a 2-1/2” diameter hole for field wiring and a

3-5/8” hole is provided for a through-the-curb connection. A

removable patch plate covers both the openings.

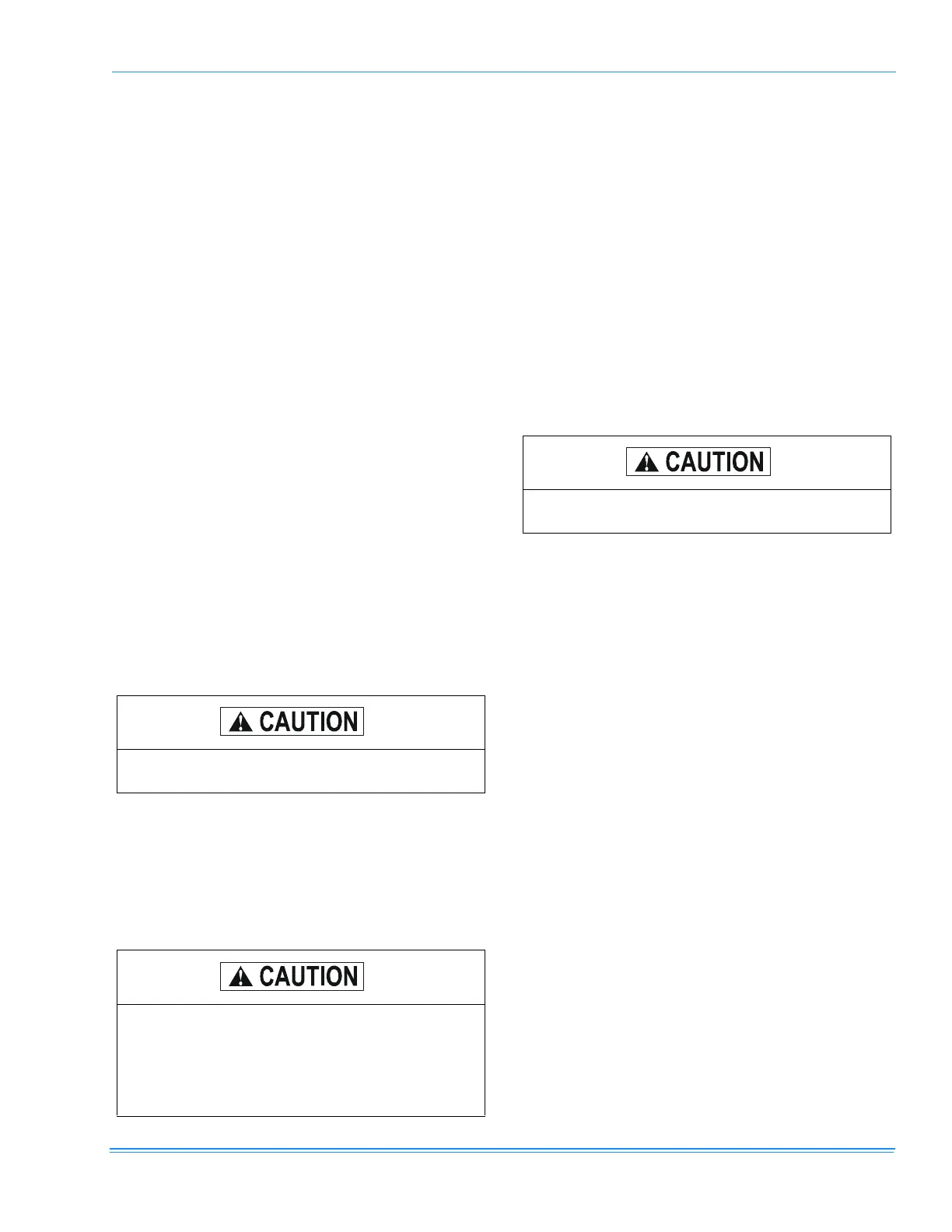

ERV

The ERV [Energy Recovery Ventilation] is a separate air han-

dler that attaches to the exhaust end of the 25-40T Millen-

nium packaged rooftop unit. The ERV is shipped separately

and assembled to the Millennium at the jobsite. An 'ERV' Mil-

lennium is shipped with an end configuration and electric

hookups designed to mate with the ERV. This option is avail-

able only with the Simplicity control, and no other power

exhaust option can be supplied if an ERV is selected.

The ERV incorporates a rotating heat exchange wheel and a

pair of exhaust blowers. It exhausts return air through the

wheel, capturing the thermal energy of the exiting hot or cold

air as it passes. As the wheel rotates, the incoming airstream,

pulled through by the supply fan, regains that energy.

The Millennium ERV has a terminal block and mating con-

nectors to simplify hooking up the two systems. The controls

of both units are factory set to interact properly. Power for the

ERV blower motors and controls is provided through the Mil-

lennium unit. The Millennium /ERV dataplate information

includes the ERV electrical load.

The Millennium Simplicity control has parameters for the

ERV; ref. the parameter list. When economizer and ERV

options are selected on the same unit, the Simplicity control

and the ERV have specific connections and internal rules for

that operation.

Also refer to the ERV Installation Instructions packaged with

the ERV.

Use care to avoid damage when drilling holes for

the disconnect mounting.

When connecting electrical power and control wir-

ing to the unit, waterproof connectors MUST BE

USED so that water or moisture cannot be drawn

into the unit during normal operation. The above

waterproofing conditions will also apply when

installing a field-supplied disconnect switch.

Waterproof connections MUST be used to ensure

that water cannot penetrate the roof or roof curb.

Loading...

Loading...