102777-YIM-E-0206

18 Unitary Products Group

3. Place the flue extension (Figure 9) on the flue duct of

each furnace section and attach with screws provided.

4. Place the flue in position with the diverter angles facing

up toward the top of the unit and attach with screws pro-

vided.

5. Place the wind shield over the louvers on the right side of

the burner access door and attach with screws provided.

6. Refer to the Gas Furnace Operation Instructions in the

Start-up Section of this manual for further information.

ELECTRIC HEAT

Units with electric heat are fully wired and operational when

shipped. Constant volume units are designed for two equal

steps of capacity for 80 and 108 kWH heat; 40 kW heat is one

step only. VAV units are one full step at full heat capacity.

HOT WATER HEAT

The YORK Millennium units (25, 30, and 40 Ton sizes) can be

furnished with a YORK hot water coil as the heat source. One

or two row coil units will be factory installed in the heating

section.

NOTE: The hot water control valve will not be provided. The

installer will need to purchase a hot water control

valve, to connect the hot water piping and power

wiring at the job site for the hot water heat section to

be operational.

NOTE: For all hot water coils the entering water tempera-

ture should not exceed 200°F.

The hot water coil is located downstream of the supply air fan

and just above the supply air opening in the bottom of the

unit.

Refer to Tables 58 through 66 and Figures 36 through 49 for

flow rate and capacity.

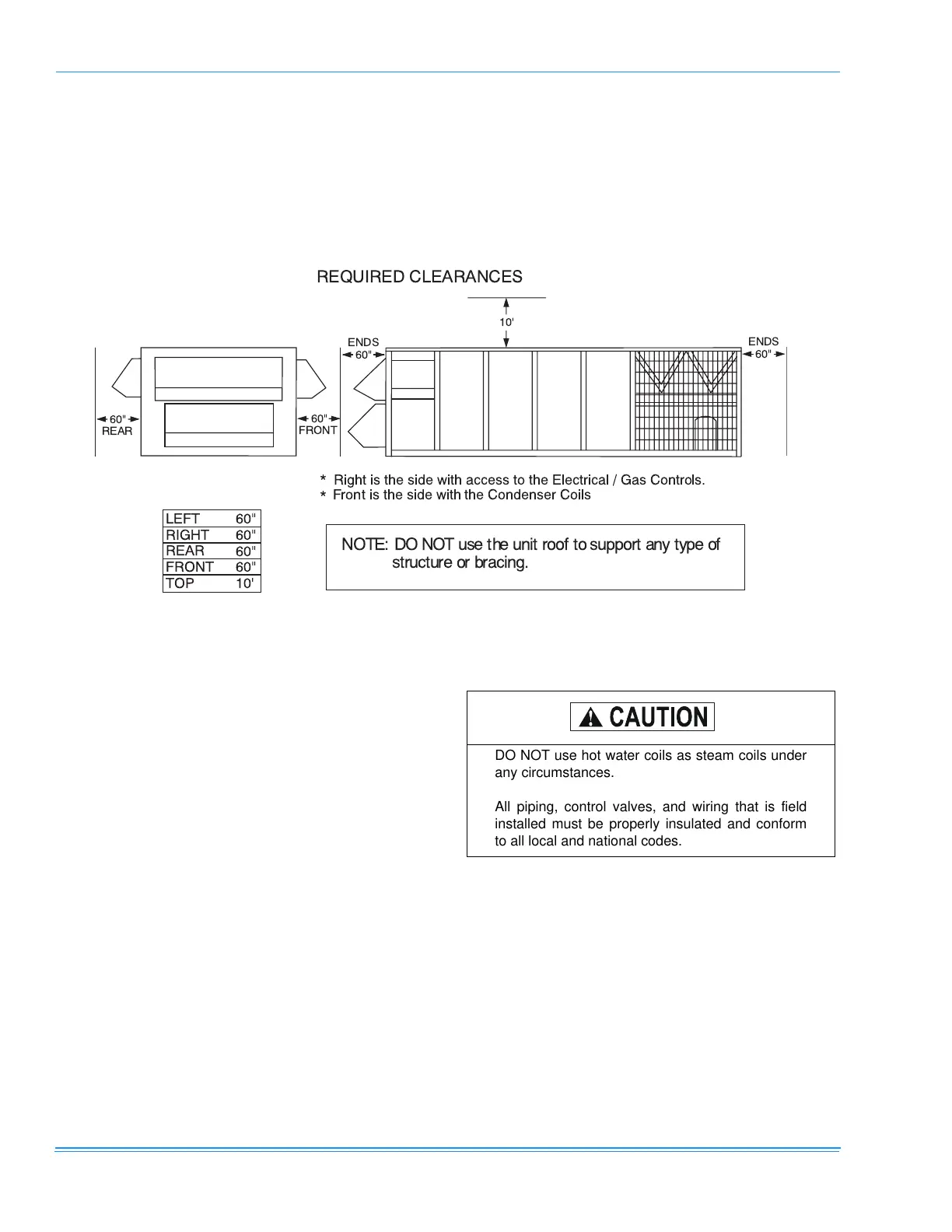

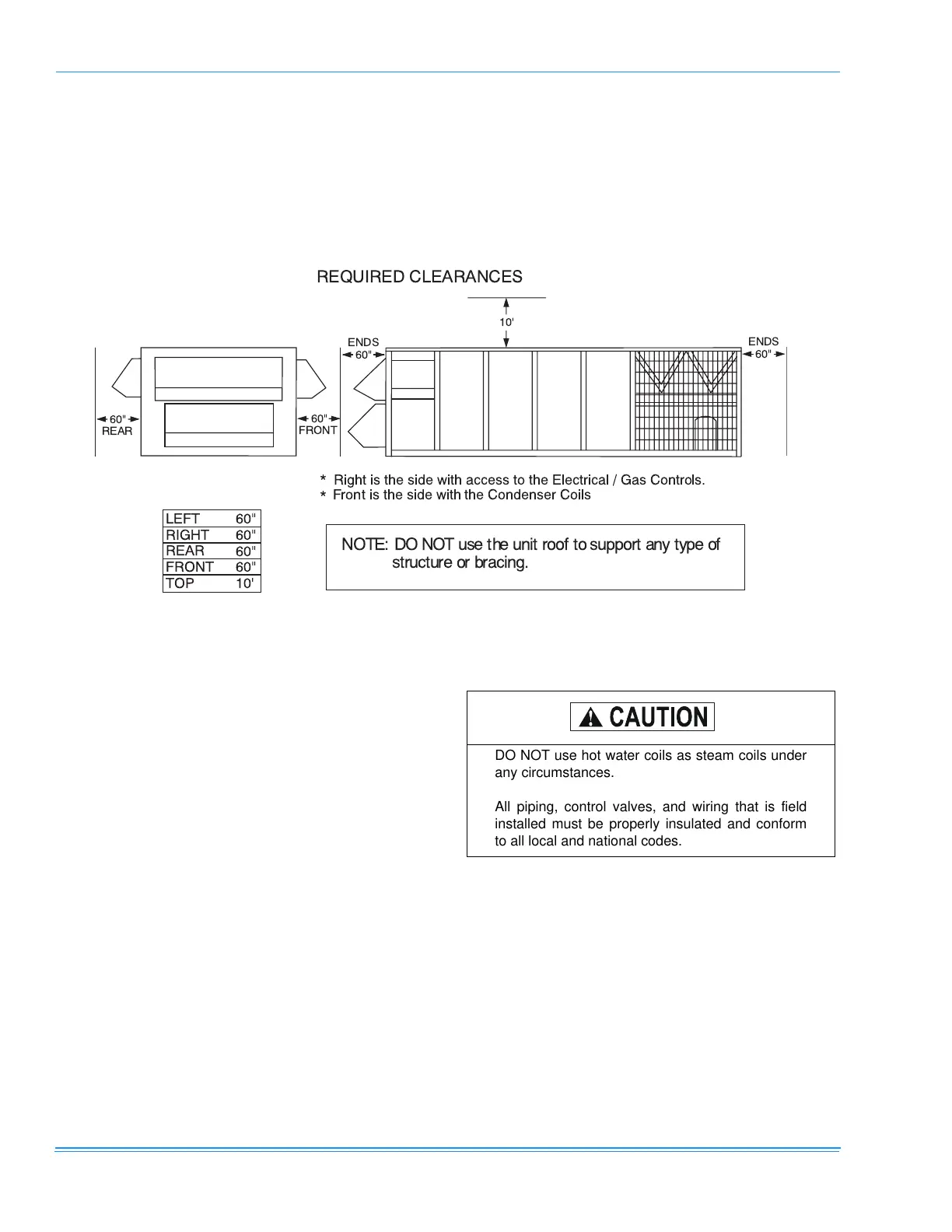

FIGURE 10 - CLEARANCES

60"

REAR

60"

FRONT

60"

ENDS

10'

60"

ENDS

REQUIRED CLEARANCES

LEFT

RIGHT

REAR

FRONT

TOP

60"

60"

60"

60"

10'

* Right is the side with access to the Electrical / G as Controls.

*

is the side with the Condenser Coils

NOT E: D O NO T u se th e unit r oof to support a ny type of

structure or b racing.

Front

DO NOT use hot water coils as steam coils under

any circumstances.

All piping, control valves, and wiring that is field

installed must be properly insulated and conform

to all local and national codes.

Loading...

Loading...