1061903-XIM-A-0713

32 Johnson Controls Unitary Products

Air Balance

Start the supply air blower motor. Adjust the resistances in both

the supply and the return air duct systems to balance the air

distribution throughout the conditioned space. The job

specifications may require that this balancing be done by

someone other than the equipment installer.

To check the supply air CFM after the initial balancing has been

completed:

1. Remove the two 5/16” dot plugs from the blower motor and

the filter access panels shown in the Unit Dimensions and

Rear View Clearances Figure 7.

2. Insert at least 8" of 1/4 inch tubing into each of these holes

for sufficient penetration into the air flow on both sides of

the indoor coil.

NOTE: The tubes must be inserted and held in a position

perpendicular to the air flow so that velocity pressure

will not affect the static pressure readings.

3. Using an inclined manometer, determine the pressure drop

across a dry evaporator coil. Since the moisture on an

evaporator coil may vary greatly, measuring the pressure

drop across a wet coil under field conditions would be

inaccurate. To assure a dry coil, the compressors should

be deactivated while the test is being run.

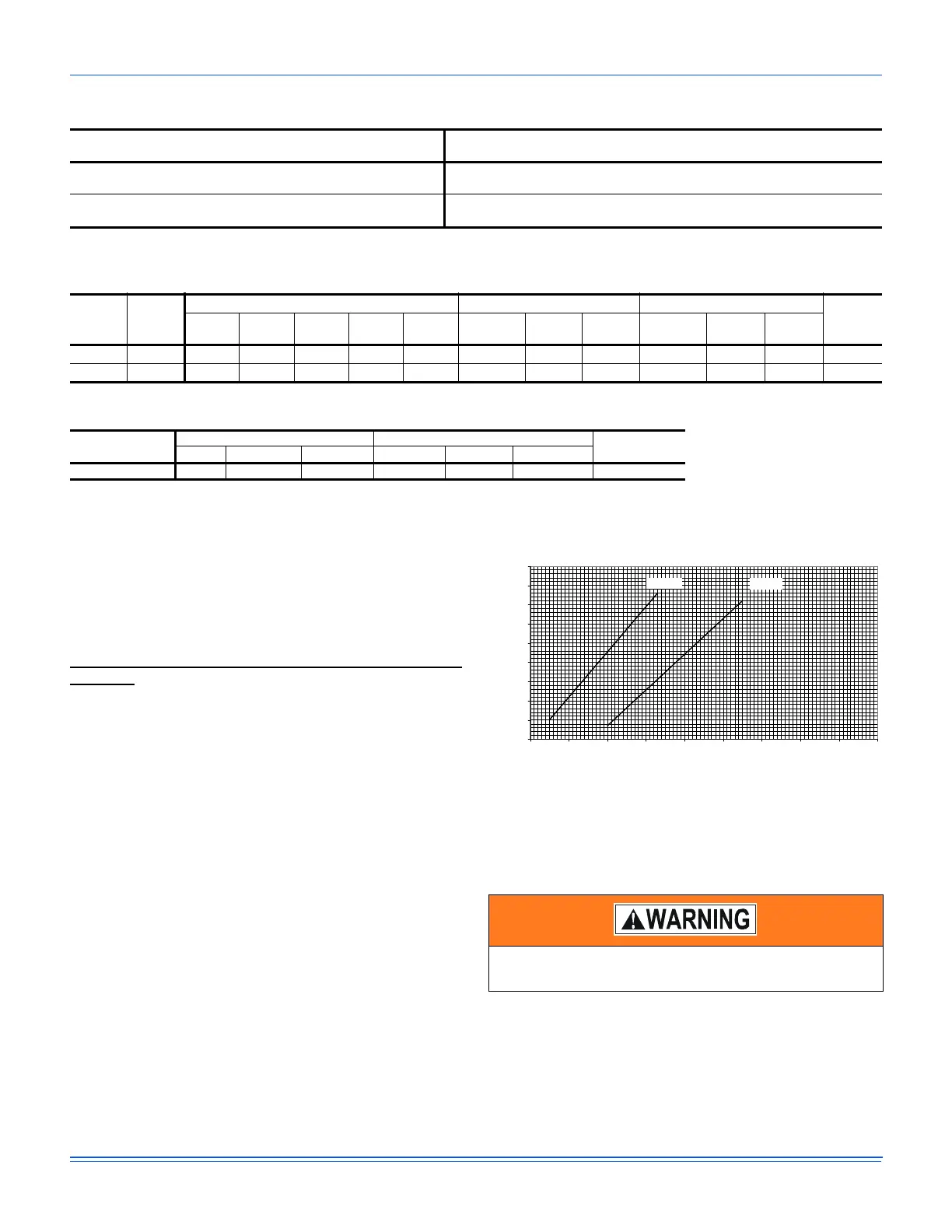

Figure 24: Pressure Drop Across A Dry Indoor Coil Vs.

Supply Air CFM For All Unit Tonnages

4. Knowing the pressure drop across a dry coil, the actual

CFM through the unit can be determined from the curve in

Pressure Drop vs. Supply Air CFM Figure 24.

After readings have been obtained, remove the tubes and

reinstall the two 5/16” dot plugs that were removed in Step 1.

NOTE: De-energize the compressors before taking any test

measurements to assure a dry indoor coil.

Table 21: RPM Selection

Size

(Tons)

Model HP Max BHP

Motor

Sheave

Blower

Sheave

6 Turns

Open

5 Turns

Open

4 Turns

Open

3 Turns

Open

2 Turns

Open

1 Turn

Open

Fully

Closed

18 0

(15)

ZF 4.1 4.72 1VP62 BK75 925 967 1009 1051 1093 1135 N/A

24 0

(20)

ZF 6.2 7.13 1VP75 BK100 895 926 956 987 1018 1049 N/A

* Maximum blower speed is 1400 RPM for ZF180 and 1200 RPM for ZF240

Table 22: Indoor Blower Specifications

Size

(Tons)

Model

Motor Motor Sheave Blower Sheave

Belt

HP RPM Eff. SF Frame

Datum Dia.

(in.)

Bore (in.) Model

Datum Dia.

(in.)

Bore (in.) Model

180 (15) ZF 4.1 1450 0.89 1.15 184T 4.4 - 5.4 1 1/8 1VP62 6.9 1 BK75 BX68

240 (20) ZF 6.2 1450 0.91 1.15 213T 5.8 - 6.8 1 3/8 1VP75 9.4 1 3/16 BK100 BX81

Table 23: Power Exhaust Specifications

Voltage

Motor Motor

CFM @

0.1 ESP

HP RPM

1

1. Motors are multi-tapped and factory wired for high speed.

QTY LRA FLA MCA

460-1-60 3/4 1075 1 4.1 2.2 2.75 5250

Failure to properly adjust the total system air quantity

can result in extensive blower damage.

PRESSURE DROP ACROSS A DRY INDOOR COIL VS

SUPPLY AIR CFM FOR ALL UNIT TONNAGES

0.25

0.3

0.35

0.4

0.45

0.5

0.55

0.6

0.65

0.7

45678910111213

NOMINAL CFM (THOUSANDS) SUPPLY AIR

PRESSURE DROP (IWG)

180MBH 240MBH

Loading...

Loading...