Instruction for use of the forklift with the triple pivot battery

24

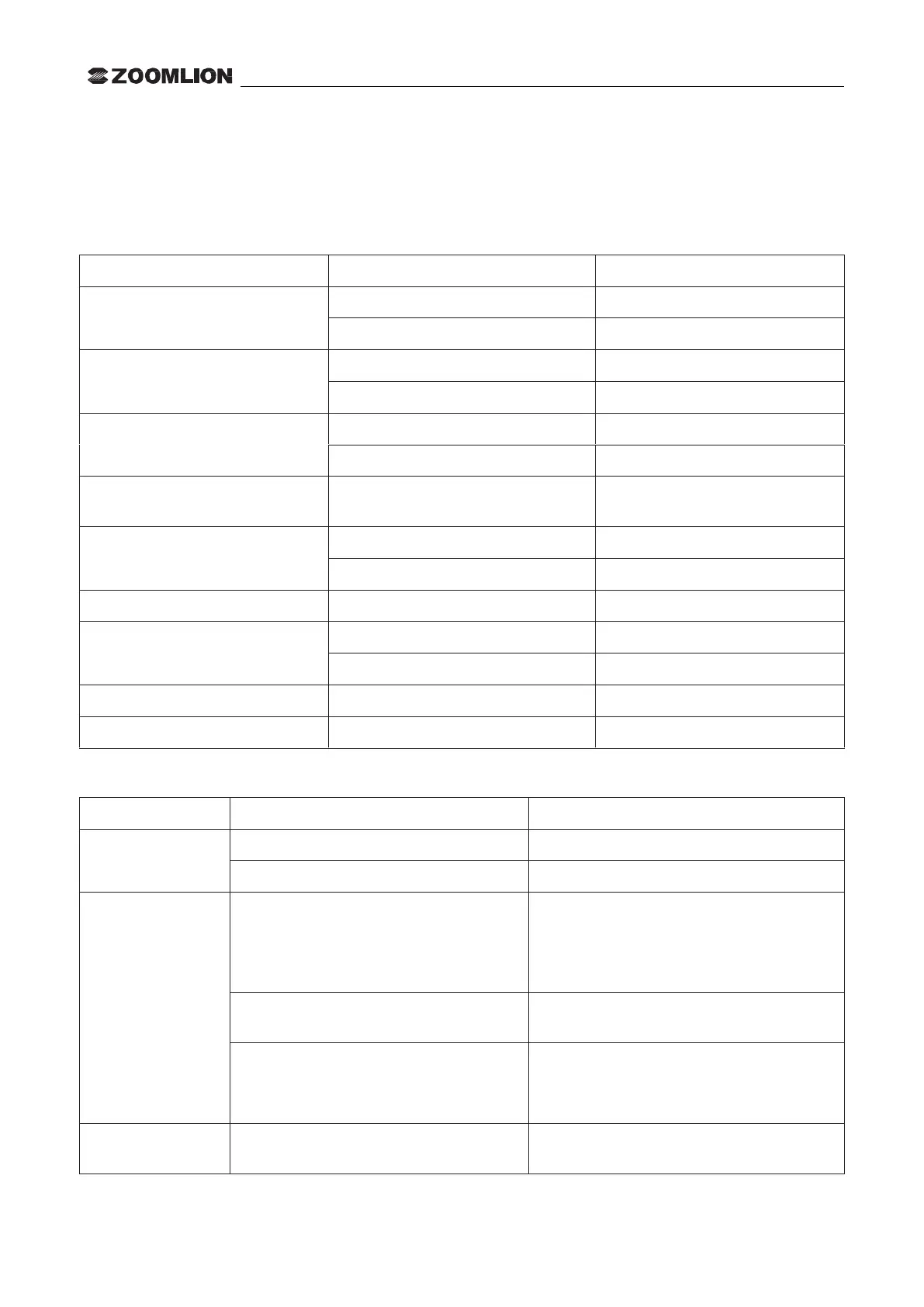

4.4.6 Hydraulic system fault diagnosis

If there is a fault in the hydraulic system, the causes should be identified according to the following table and

repair as necessary.

(1) Multi-way valve

The pressure of lifting oil line

cannot increase

Cleaning after disassembly

Cleaning after disassembly

The shock pressure increases

slowly

Cleaning after disassembly

The pressure of steering oil line is

more than the specified value

Cleaning after disassembly

Cleaning after disassembly

Failed to reach the specified oil

amount

Improperly adjusted overflow valve

Improperly adjusted overflow valve

O ring is aged or damaged

The surface of valve seat is damaged

Adjust or replace the relief valve

The surface of valve seat is damaged

Amend the surface of valve seat

Cleaning after disassembly

Low level in the oil tank

Refuel up to the specified amount

Oil pipe or filter is clogged

Clean or replace as needed

The lining board is damaged

The support is damaged

The seal ring, bushing seals or check ring

are in poor condition.

The relief valve is improperly adjusted

A pressure gauge should be used to adjust the

relief valve pressure to the specified value

There is air in the system

Retighten the oil pipe at the suction side

Refueling

Change oil seal of oil pump

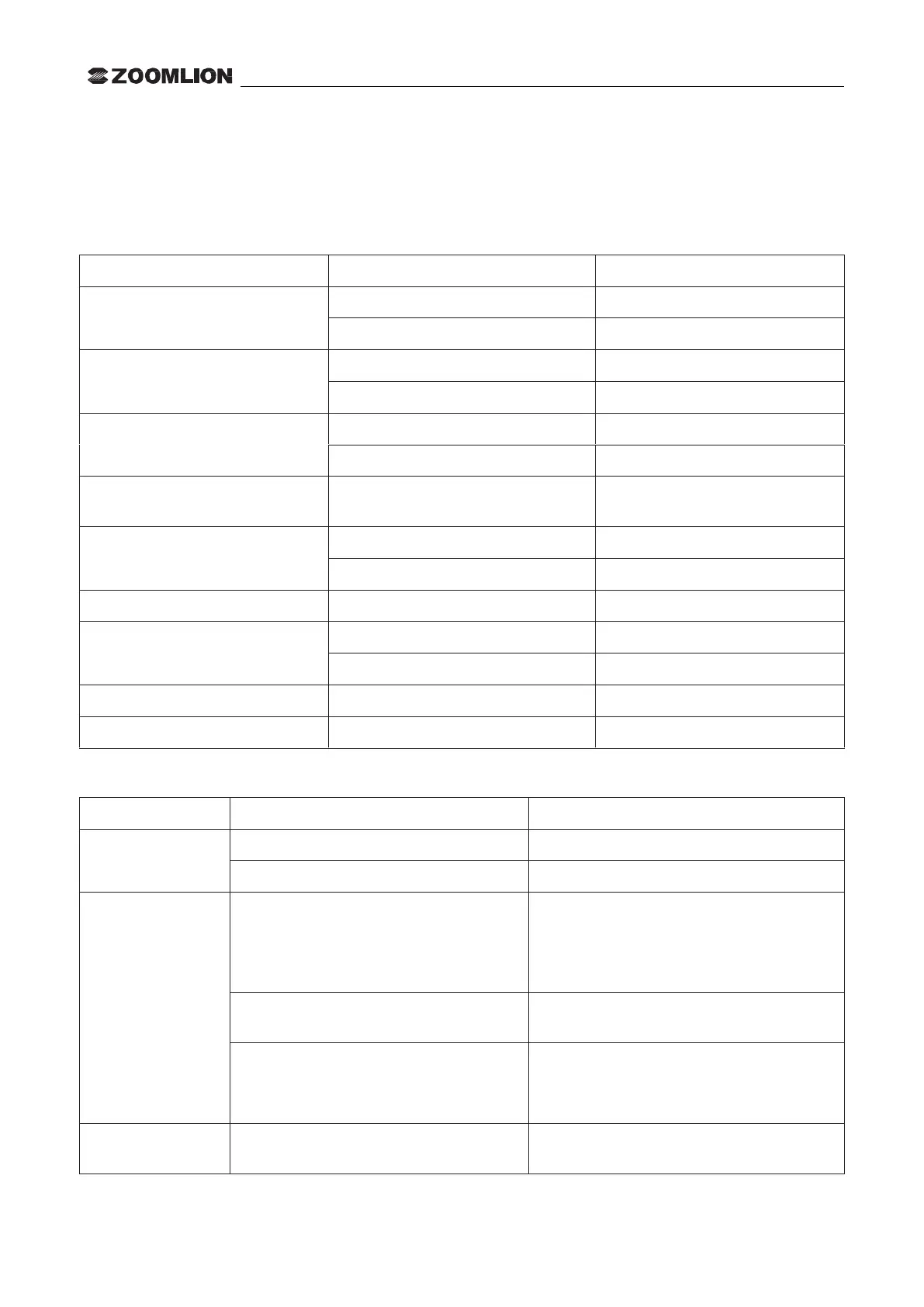

Noise is produced

only once in

The oil suction pipe is damage or oil filter

is clogged

Check the pipes or maintain the oil filter.

Loading...

Loading...