28

Note:

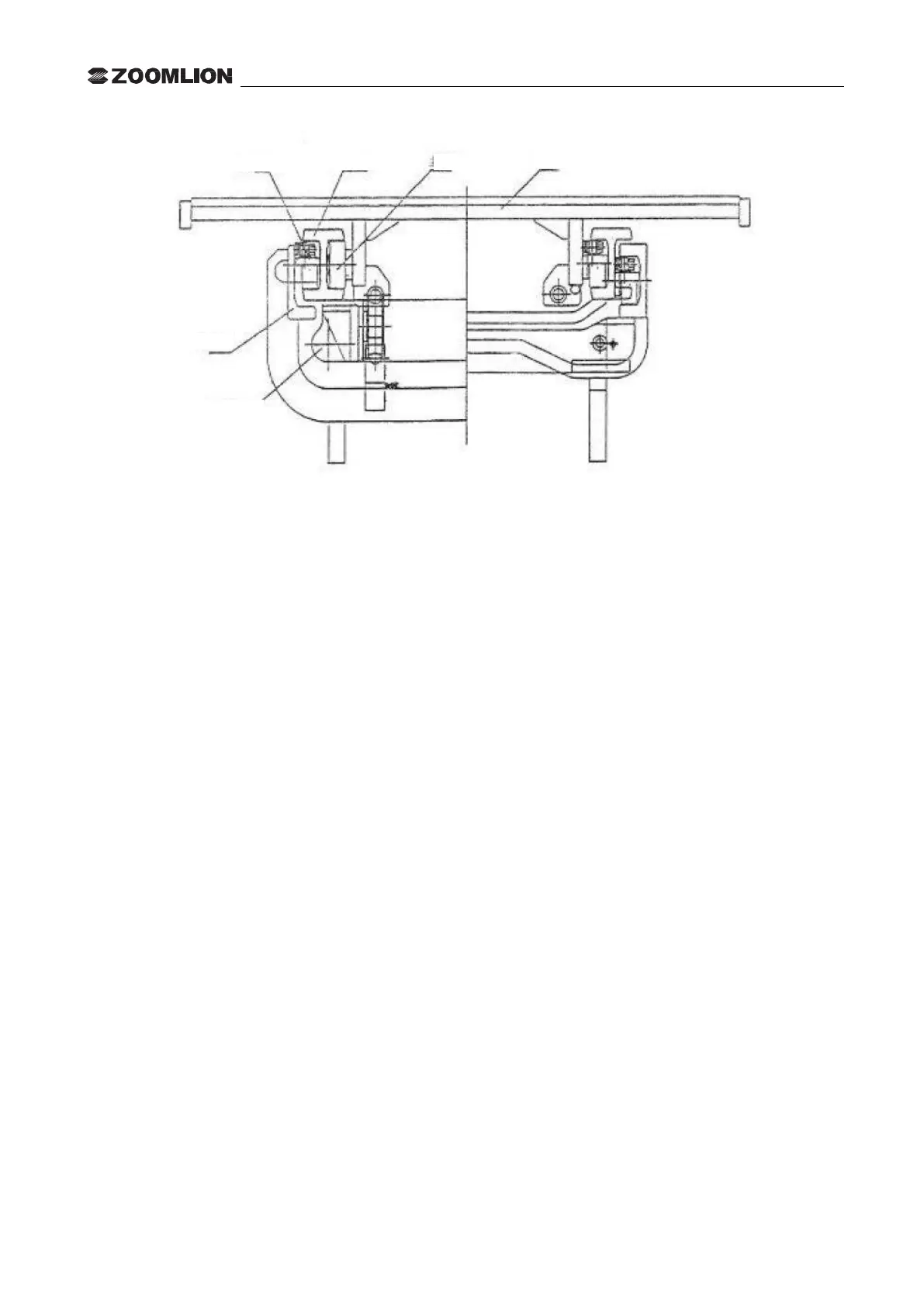

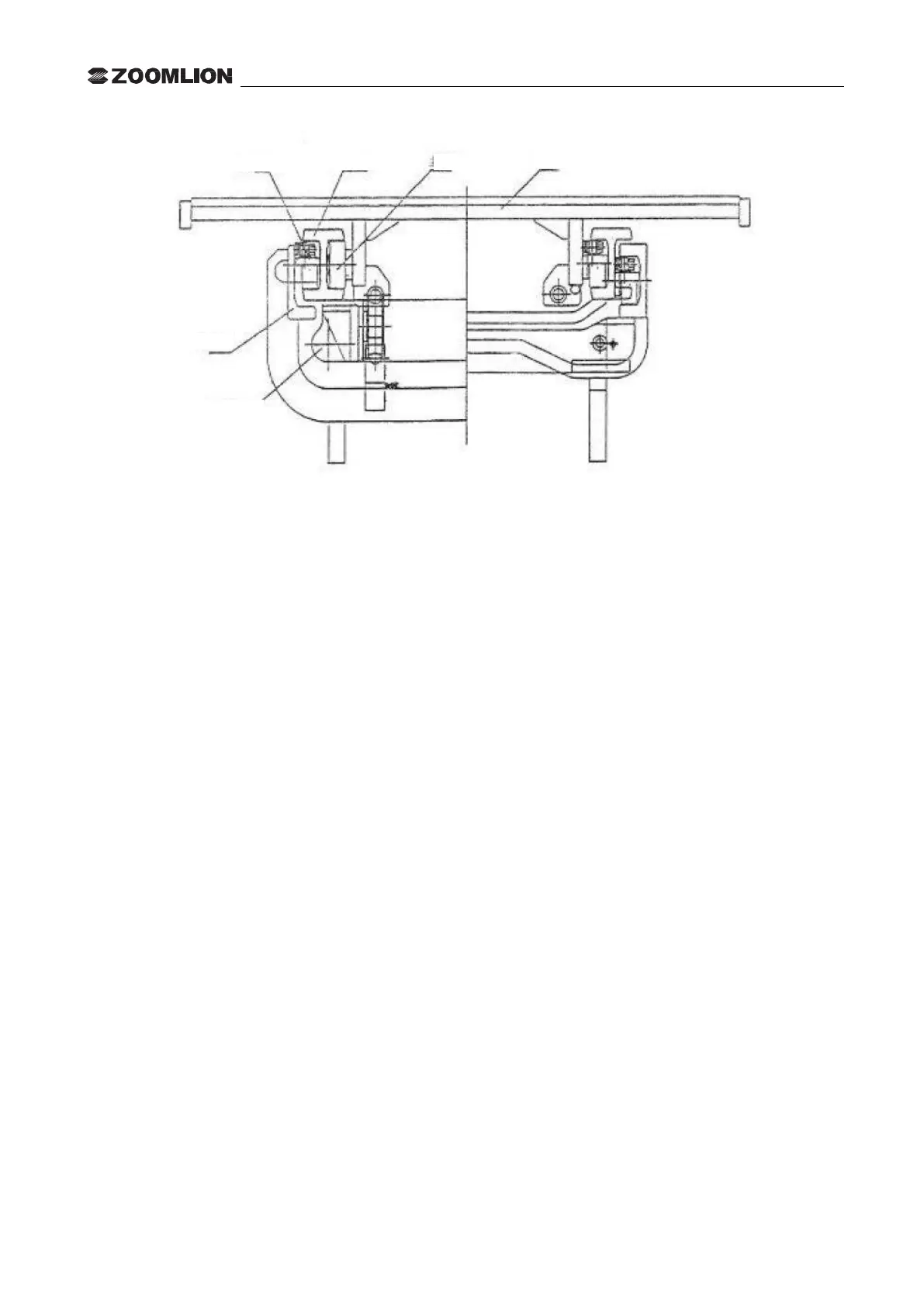

(a) Adjust the space of side roller to 0.5mm;

(b) Add grease on the surface of main roller and contact area of mast

Fig.4-20 Position of roller

4.5.4 Forklift fittings

Because different occasions where the forklift is used and various loaded cargos, the common pallet fork with

the single forking function cannot meet the demands of many working conditions. The forklift fittings belong to

one part of the forklift working device. Its rational application makes the forklift a kind of multi-purpose, high

efficient materials handling tool, which can fork, clamp, lift, rotate, move sideway, push and pull or rollover,

and considerably widen the scope of forklift application, enhance the handling efficiency of forklift and

promote the automation development level of material handling industry. There are many types of forklift

fittings with their different performances to meet the requirements of different working environment. Hence the

methods of their classification also vary. According to the oil line needed by the fittings, the fittings are divided

into the mechanic and hydraulic types. The former needs no auxiliary refueling line, the original working device

of forklift possesses the lifting and tilting oil lines, which are fitted with the 2PC valve: E.g.: Through-bar, jib,

foldable pallet fork etc., It is necessary for the latter to be added with an auxiliary refueling circuit (group I or

II). These fitted with the group I of auxiliary refueling circuit is normally referred to "3PC valve fittings" which

possess a single function: these fitted with the group II of auxiliary refueling circuit normally referred to "4PC

valve fittings which have two singles functions and so on. Each time a single function is added, it is necessary

to supplement a group of auxiliary refueling circuit, and one piece of multi-way valve will be added. E.g.: side

shifter (3PC valve fittings), rotating clamp (4PC valve fittings), pusher (3PC valve fittings) etc.

Loading...

Loading...