Required equipment

NoteSpare part no.Equipment, etc.

Standard and Foundry.3HAC10814-1Wrist, 5 kg

Loctite 574-Locking liquid

The content is defined in the section

Standard tools on page 229.

-Standard toolkit

These procedures include references

to the tools required.

Other tools and procedures may

be required. See references to

these procedures in the step-by-

step instructions below.

CAUTION

Always cut the paint with a knife and grind the paint edge when disassembling

parts. See Cut the paint or surface on the robot before replacing parts on page 117.

Removal, wrist unit

The procedure below details how to remove the wrist from the robot upper arm.

The wrist, which includes axes 5 and 6, is a complete unit comprising drive units

and gearboxes. It is a replacement unit of complex design and should not normally

be serviced on-site. Instead it should be sent to ABB for service etc.

ABB recommends its customers to carry out only the following servicing and repair

work on the wrist.

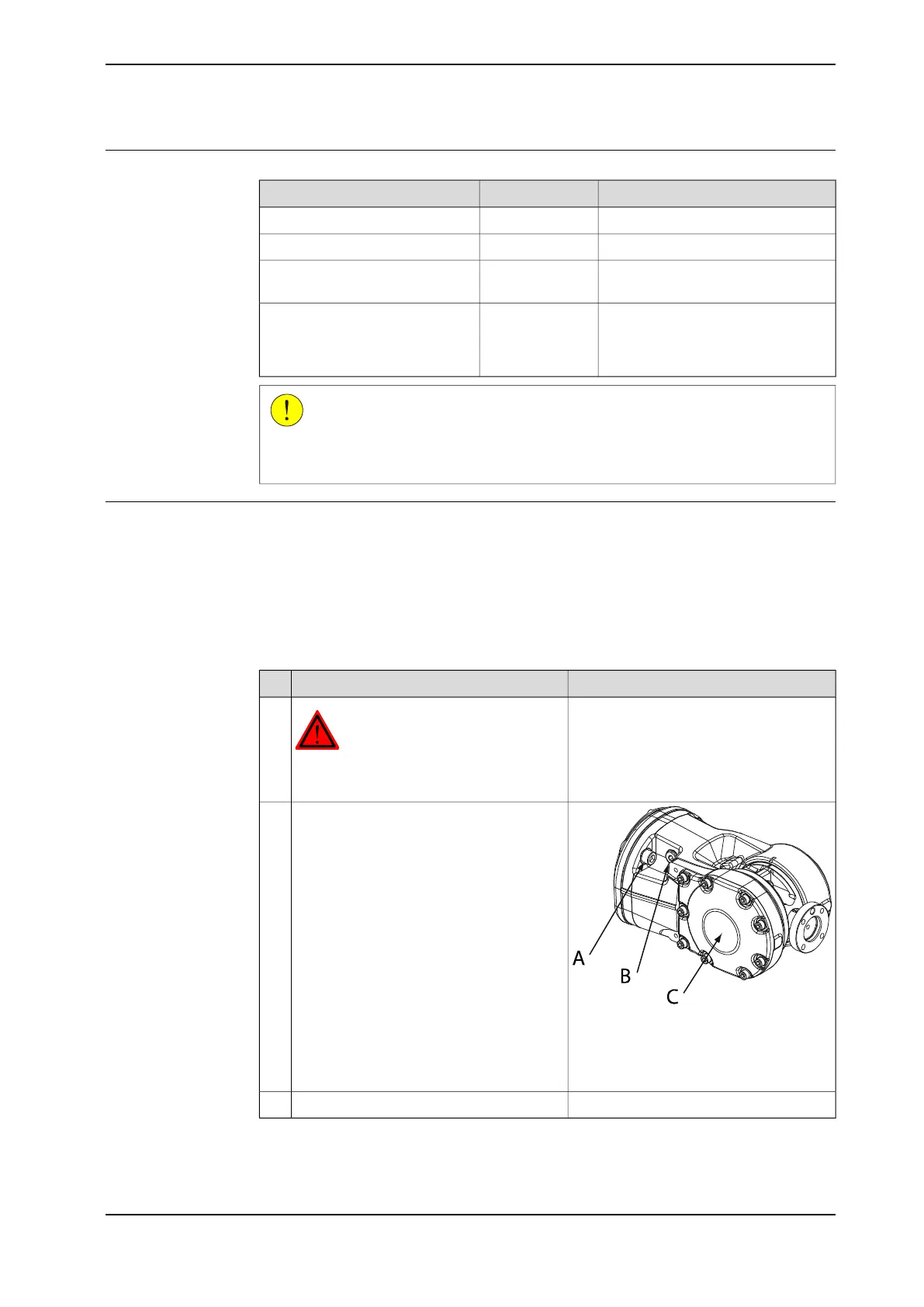

Note/IllustrationAction

DANGER

Turn off all electric power, hydraulic and

pneumatic pressure supplies to the robot!

1

xx0300000104

Remove the oil plug from the wrist and

drain it from all the oil.

2

A Screw

B Oil plug (air inlet)

C Wrist unit

Undo the screws and remove the wrist.3

Continues on next page

Product manual - IRB 2400 139

3HAC022031-001 Revision: P

© Copyright 2004-2018 ABB. All rights reserved.

4 Repair

4.4.2 Replacement of wrist IRB 2400L

Continued

Loading...

Loading...