2-52 Carrier (PWM) Frequency

Carrier (PWM)

Frequency

See page 1-3 for derating guidelines as they relate to carrier frequency.

In general, the lowest possible switching frequency that is acceptable for

any particular application is the one that should be used. There are several

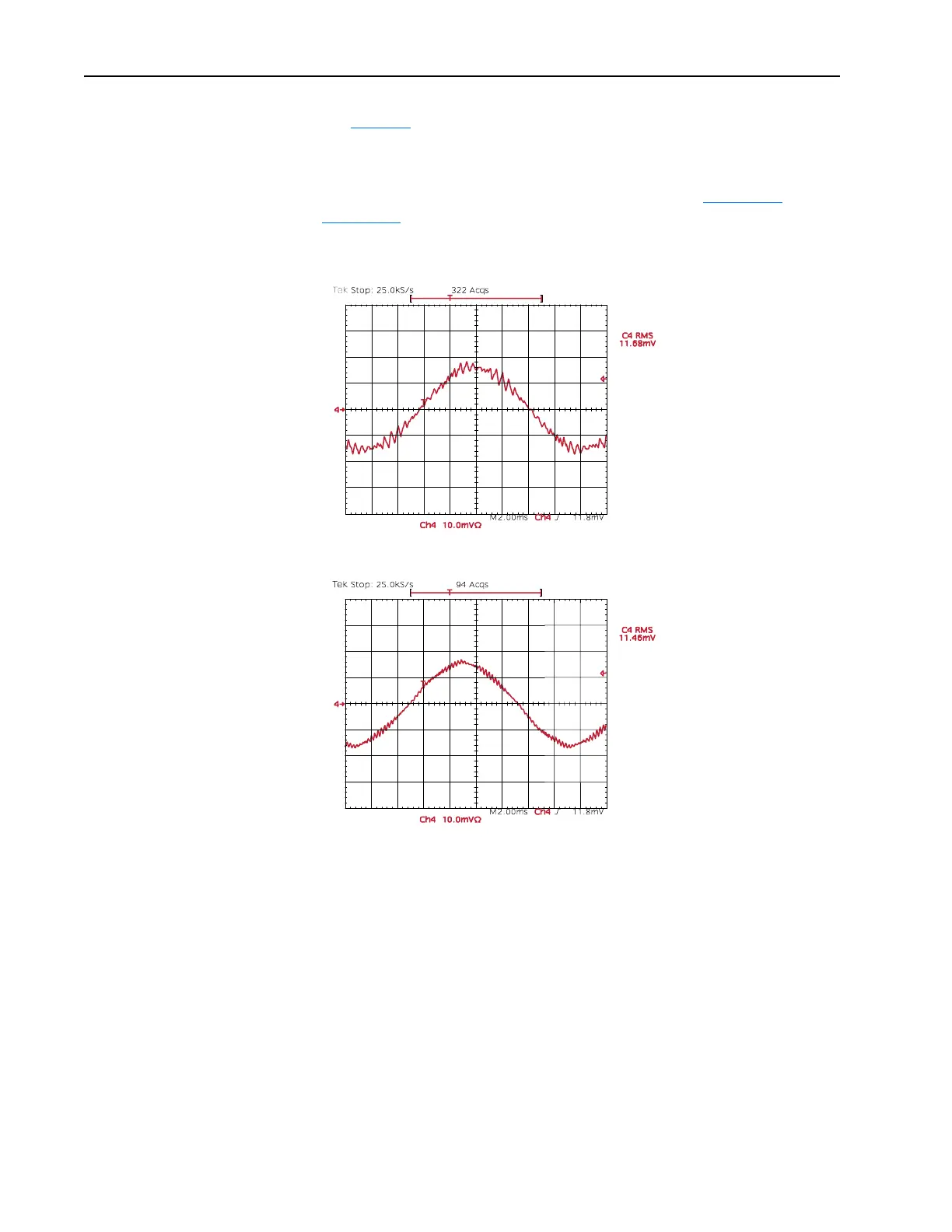

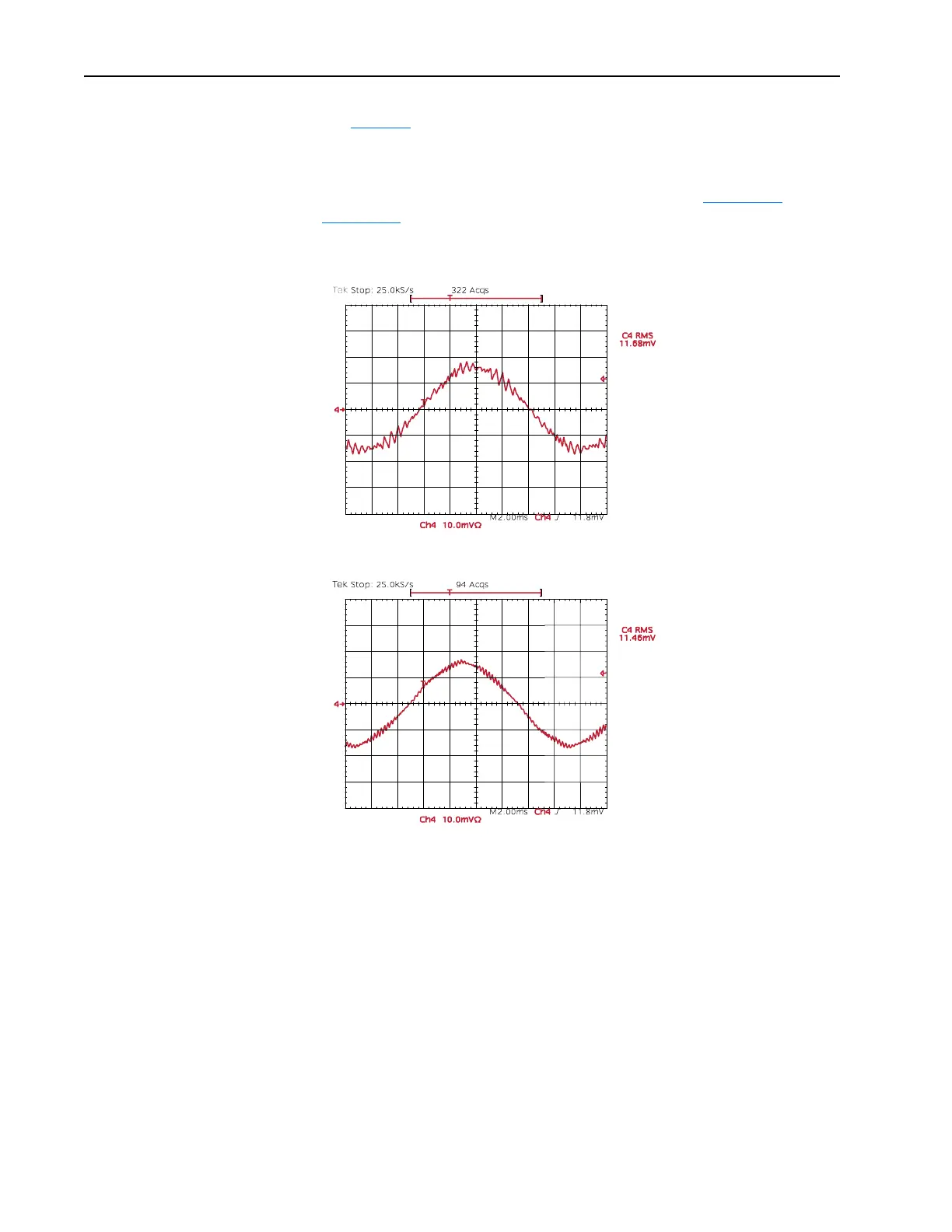

benefits to increasing the switching frequency. Refer to Figure 2.14

and

Figure 2.15

. Note the output current at 2 kHz and 4 kHz. The “smoothing”

of the current waveform continues all the way to 10 kHz.

Figure 2.14 Current at 2 kHz PWM Frequency

Figure 2.15 Current at 4 kHz PWM Frequency

The benefits of increased carrier frequency include less motor heating and

lower audible noise. An increase in motor heating is considered negligible

and motor failure at lower switching frequencies is very remote. The higher

switching frequency creates less vibration in the motor windings and

laminations thus, lower audible noise. This may be desirable in some

applications.

Some undesirable effects of higher switching frequencies include derating

ambient temperature vs. load characteristics of the drive, higher cable

charging currents and higher potential for common mode noise.

A very large majority of all drive applications will perform adequately at

2-4 kHz.

Loading...

Loading...