8 Rockwell Automation Publication 750-QS001A-EN-P - March 2015

Step 2: Validate the Drive Installation

Step 2: Validate the Drive Installation

It is important that you thoroughly inspect each of your drive installations before applying power for the first time. This is

especially important if you did not personally perform the installation tasks. Satisfy yourself now that each drive is ready to

be energized when you get to

Step 3: Power Up, Configure the Drive, and Spin the Motor Shaft.

Identify Which Drive You Have

There are two types of PowerFlex 750-Series drives, the PowerFlex 753 and the PowerFlex 755. There are some important

differences between the drives that need to be considered in subsequent steps. If you don’t know how to determine what

type of drive you have, see

Determine Drive Type on page 22.

Verify Power Wiring

Visually inspect the power wiring connections to each drive. Be sure you are satisfied that the correct wires are connected to

the input terminals and to the output terminals. See

Power Wiring on page 23 for more information on where these

connections are made.

ATTENTION: To avoid an electric shock hazard, the drive must be locked and tagged before continuing Step 2: Validate the Drive

Installation. Failure to comply can result in personal injury and/or equipment damage.

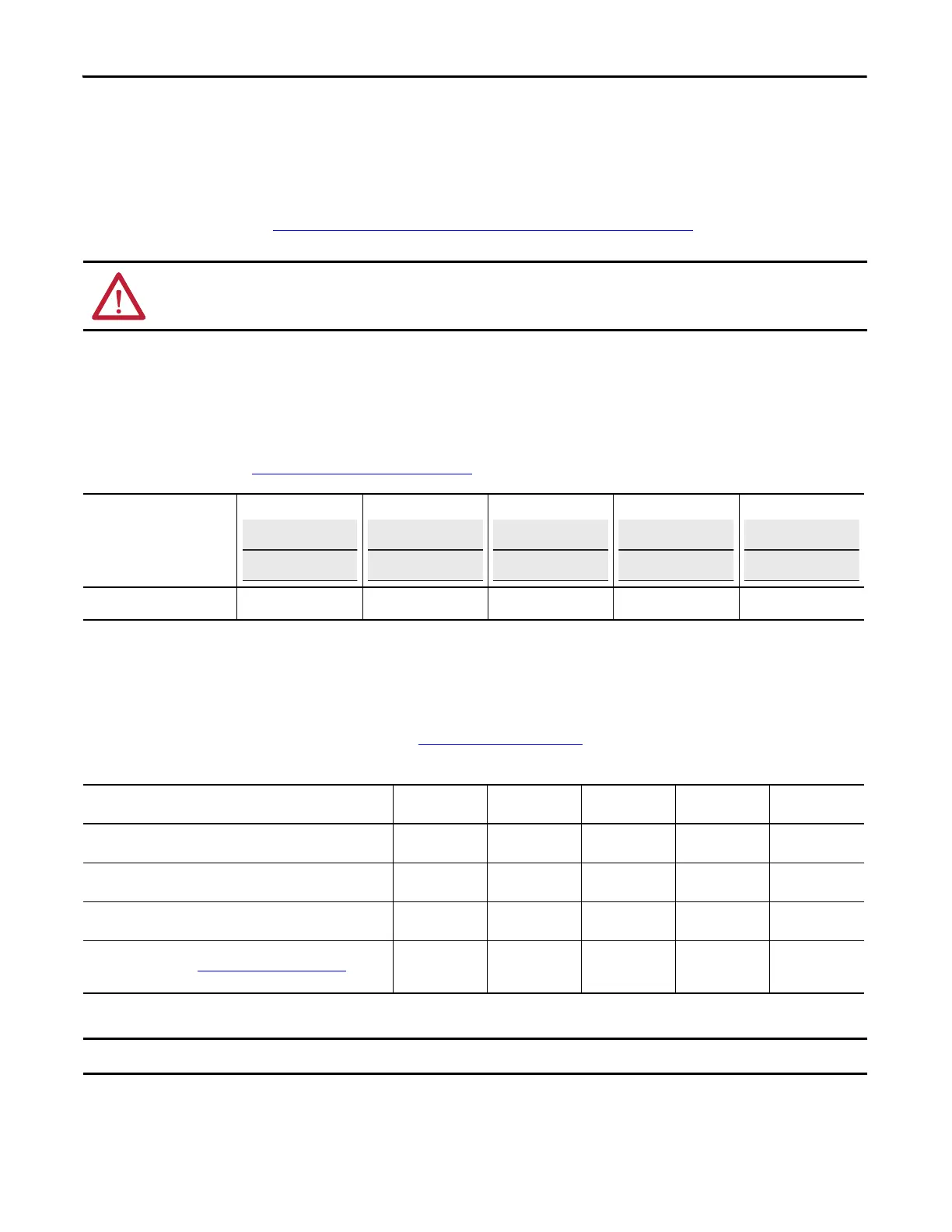

Drive/Motor Name

(example, Main Exhaust Fan)

Drive/Motor 1: Drive/Motor 2: Drive/Motor 3: Drive/Motor 4: Drive/Motor 5:

Installed Drive

❑ 753 ❑ 755 ❑ 753 ❑ 755 ❑ 753 ❑ 755 ❑ 753 ❑ 755 ❑ 753 ❑ 755

Verify Wiring

Drive 1

Wiring is Correct

Drive 2

Wiring is Correct

Drive 3

Wiring is Correct

Drive 4

Wiring is Correct

Drive 5

Wiring is Correct

AC input power is on L1, L2, L3 / R, S, T.

❑ ❑ ❑ ❑ ❑

Output motor connection is on T1, T2, T3 / U, V, W.

❑ ❑ ❑ ❑ ❑

Proper ground wire terminations at PE ground studs.

❑ ❑ ❑ ❑ ❑

If equipped, dynamic brake resistor connection is on BR1 and BR2.

If wires are present, go to Dynamic Brake Resistor on page 66 to record

dynamic brake resistor nameplate information.

❑ ❑ ❑ ❑ ❑

Rockwell Automation recommends that XLPE-type cabling be used on output of the drive.

Loading...

Loading...