Instruction Book

101 9829 2115 69

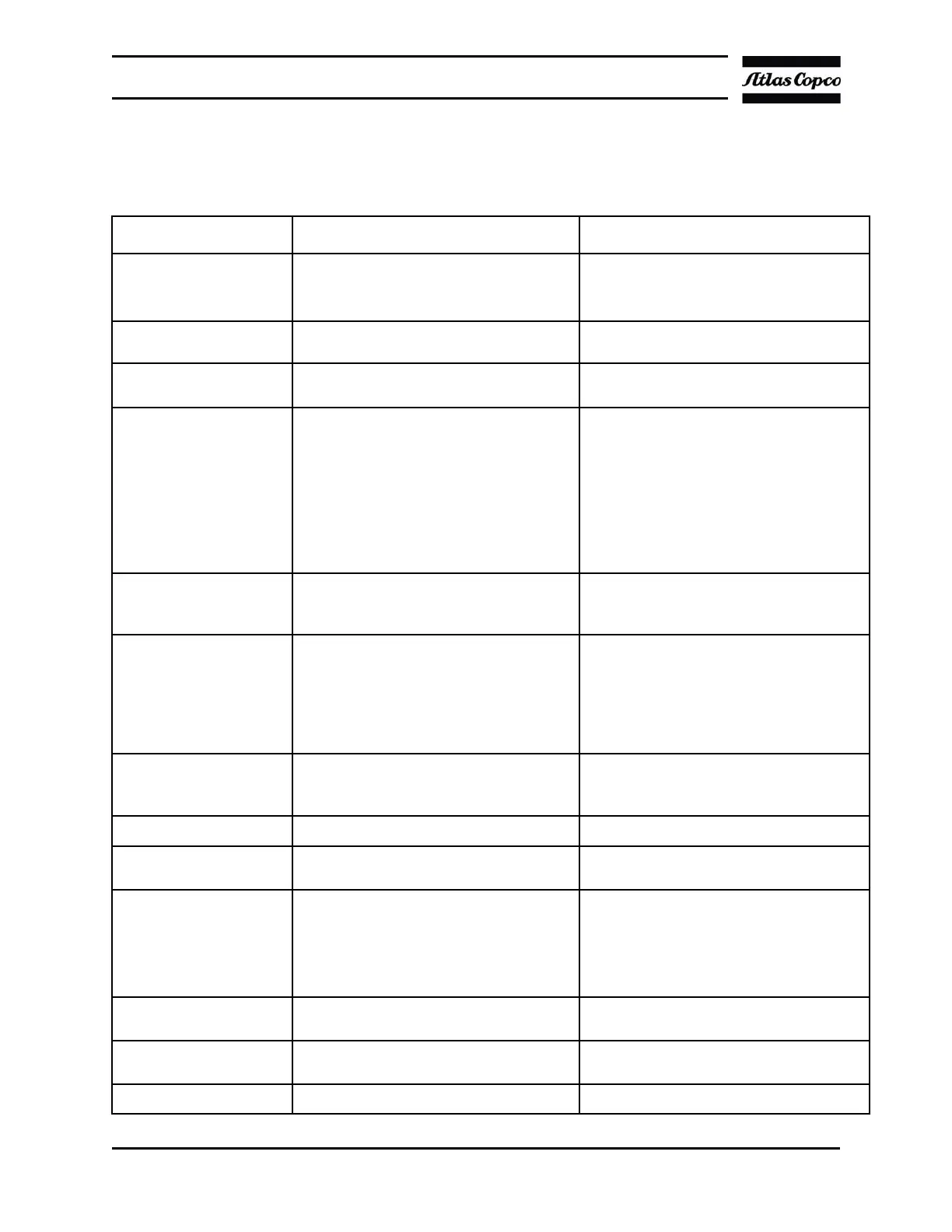

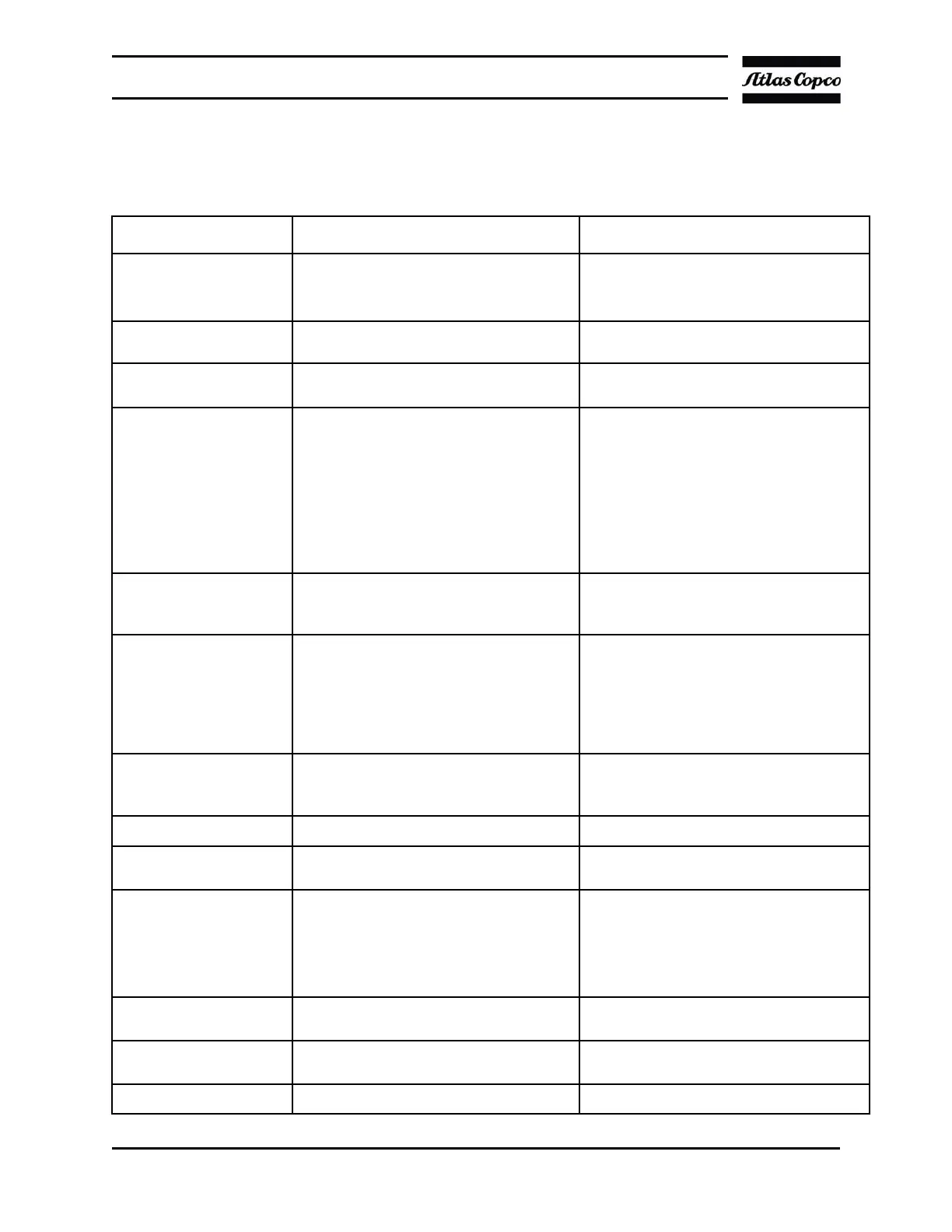

9 Troubleshooting

9.1 Troubleshooting

Symptom Possible cause Corrective action

Poor dewpoint Free water in compressed air inlet

Check the condensate separators and

drains upstream of the dryer if they are

operating correctly

Temperature of compressed air is too

high

Clean compressor after-cooler

Working pressure is too low

Check outlet pressure of compressor and

check pressure drop over dryer, filters

Poor regeneration

• Too small purge nozzle for higher

working pressure installed.

• Regeneration silencers clogged.

Check the service indicator. The

regeneration pressure should be less

than 300 mBar

• Check if all other described symptoms

are applicable. Solve them

Poor desiccant

Replace desiccant. Check the

maintenance schedule for normal

replacement periods

Damaged desiccant

• Air flow too high during start-up.

Replace desiccant. Install sonic nozzle to

avoid problems in the future

• High pressure difference between

vessels when switching. This indicates

that a too small purge nozzle is installed

Oil vapors adsorbed by desiccant

Remove some desiccant from the bottom

part of the vessel. Yellow colored

desiccant indicates oil vapor adsorption

Dryer is stopped Check that the dryer is turned on.

Desiccant has become oversaturated for

a longer period

Replace desiccant

Too high purge

consumption

Incorrect purge nozzle installed.

Compare the actual working pressure

with the ordered optimized purge nozzle.

Higher working pressures result in higher

purge consumption that creates more

noise.

The dryer produces a lot

of noise

Incorrect purge nozzle installed.

See symptom Too high purge

consumption

Safety valve of silencer is opened

See symptom Too high purge

consumption

Check the silencers and their fixation Replace the silencer if necessary

Loading...

Loading...