Instruction Book

9829 2115 69 108

11 Instructions for Use of Air Dryer

General

1. This dryer vessel can contain pressurized air; this can be potentially dangerous if the

equipment is misused.

2. This vessel must only be used as a compressed air vessel and must be operated within

the limits specified on the data plate.

3. No alterations must be made to this vessel by welding, drilling or any other mechanical

method without the written permission of the manufacturer.

4. The pressure and temperature of this vessel must be clearly indicated.

5. The safety valve must correspond with pressure surges of 1.1 times the maximum

allowable operating pressure. This should guarantee that the pressure will not

permanently exceed the maximum allowable operating pressure of the vessel.

6. Original bolts have to be used after opening for inspection. The maximum torque has to

be taken into consideration: for M12 bolts 73 Nm (53.84 Ibf.ft) +/-18 Nm (+/-13.28 Ibf.ft),

for M16 bolts 185 Nm (136.40 lbf.ft) +/-45 Nm ( +/-33.19 lbf.ft), for M20 bolts 333 Nm

(245.52 lbf.ft) +/-83 Nm (+/- 61.20lbf.ft)

Guidelines for inspection

On the Declaration of Conformity / Declaration of Incorporation the harmonized and/or other

standards that have been used for the design are shown and/or referred to. The

Declaration of Conformity / Declaration of Incorporation is part of the documentation that is

supplied with this dryer.

Local legal requirements and/or use outside the limits and/or conditions as specified by Atlas

Copco may require other inspection periods as mentioned below.

Pressure equipment

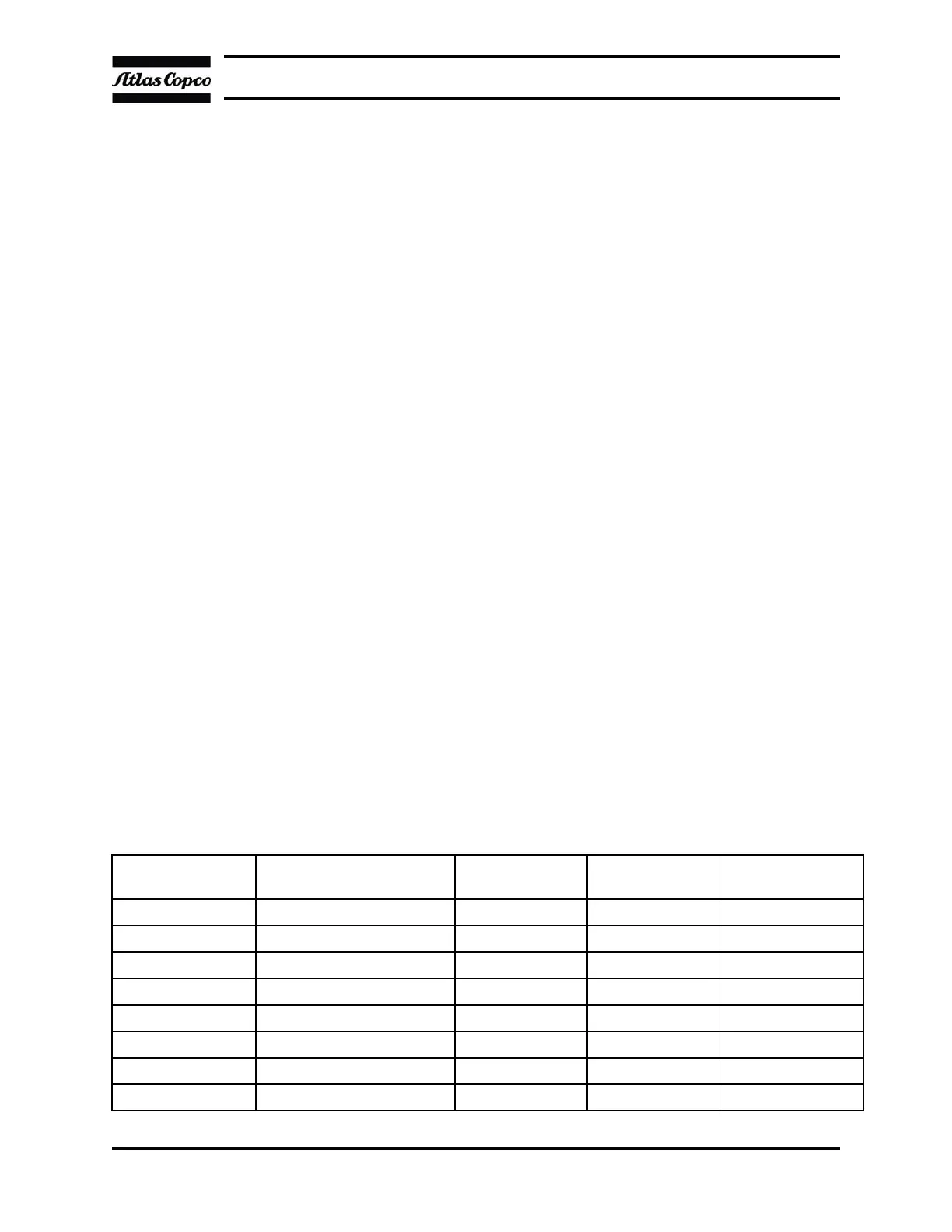

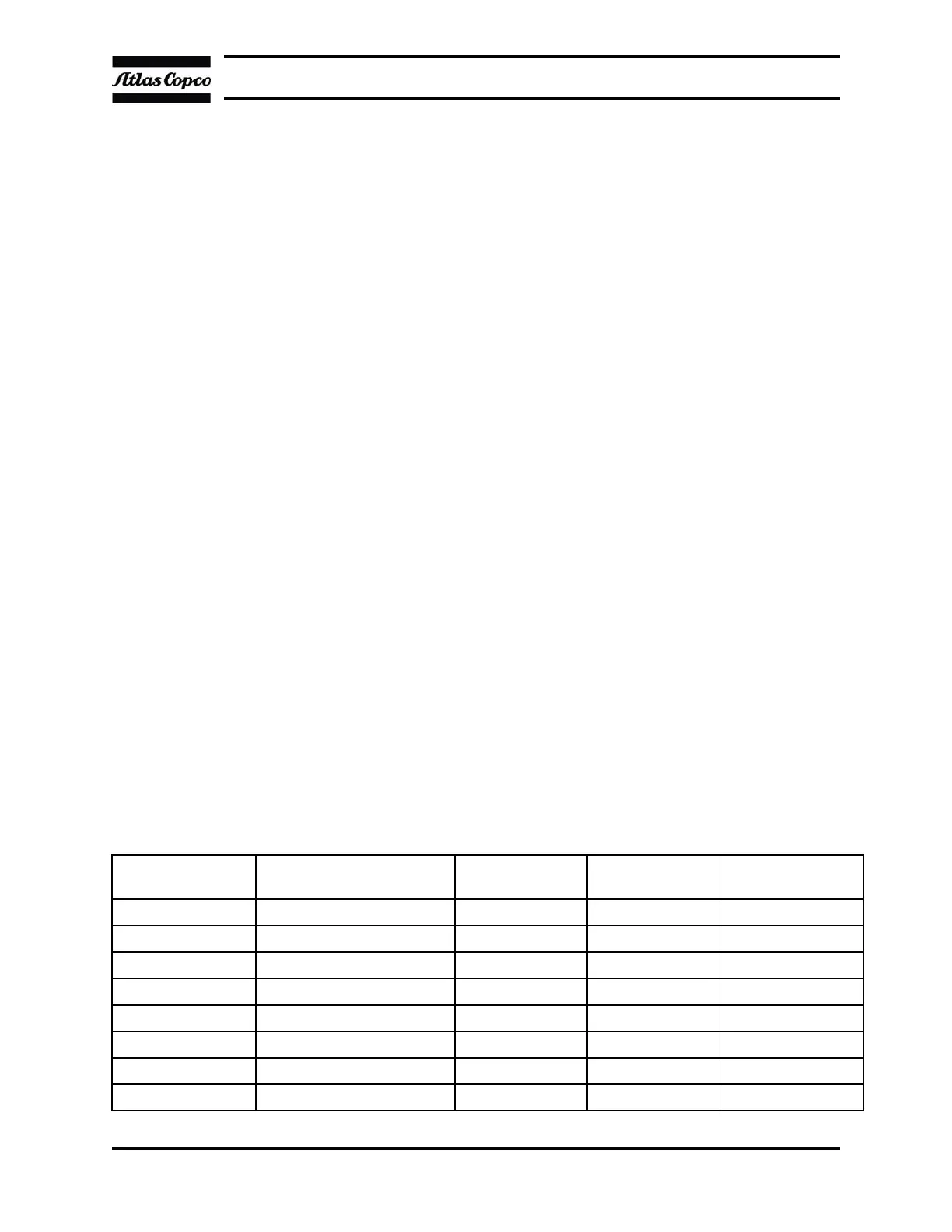

The following tables A and B contain the necessary information for the inspection of all

pressure equipment of category ll and higher according to the Pressure Equipment Directive

97/23/EC.

Design criteria for pressure equipment

Table A

Dryer Type

Construction Drawing no.

Design Pressure

PSIG

Vessel Diameter

(INCH)

Vessel Internal

Volume (GAL)

CD 350+

1624 5200 00

165 24 118

CD 425+

1624 5200 00

165 24 118

CD 500+

1624 5201 00

165 30 115

CD 700+

1624 5202 00

165 36 220

CD 850+

1624 5202 00

165 36 220

CD 1100

1624 5203 00

165 36 316

CD 1250

1624 5335 00 / 1624 5336 00

165 42 380

CD 1400

1624 5335 00 / 1624 5336 00

165 42 380

Loading...

Loading...