p. 20/46

TLxx-MT-EN-04

6.5. RECOMMENDED TOOLS

13

• Standard electrical tools.

• Flat spanner set.

• Set of Allen keys.

• Spirit level.

• Hammer drill + concrete drill bit - Ø 15 x 100

• Standard protective equipment: gloves, goggles, hard hat and safety shoes.

6.6. PRELIMINARY WORK

• The turnstile has been specially packaged for transport. Bring the material to the installation site with the help of

a forklift truck and remove the packing material.

• Unlock the cover and open it (TL2) or the front panel (TL1). The keys are supplied as accessories in a separate bag.

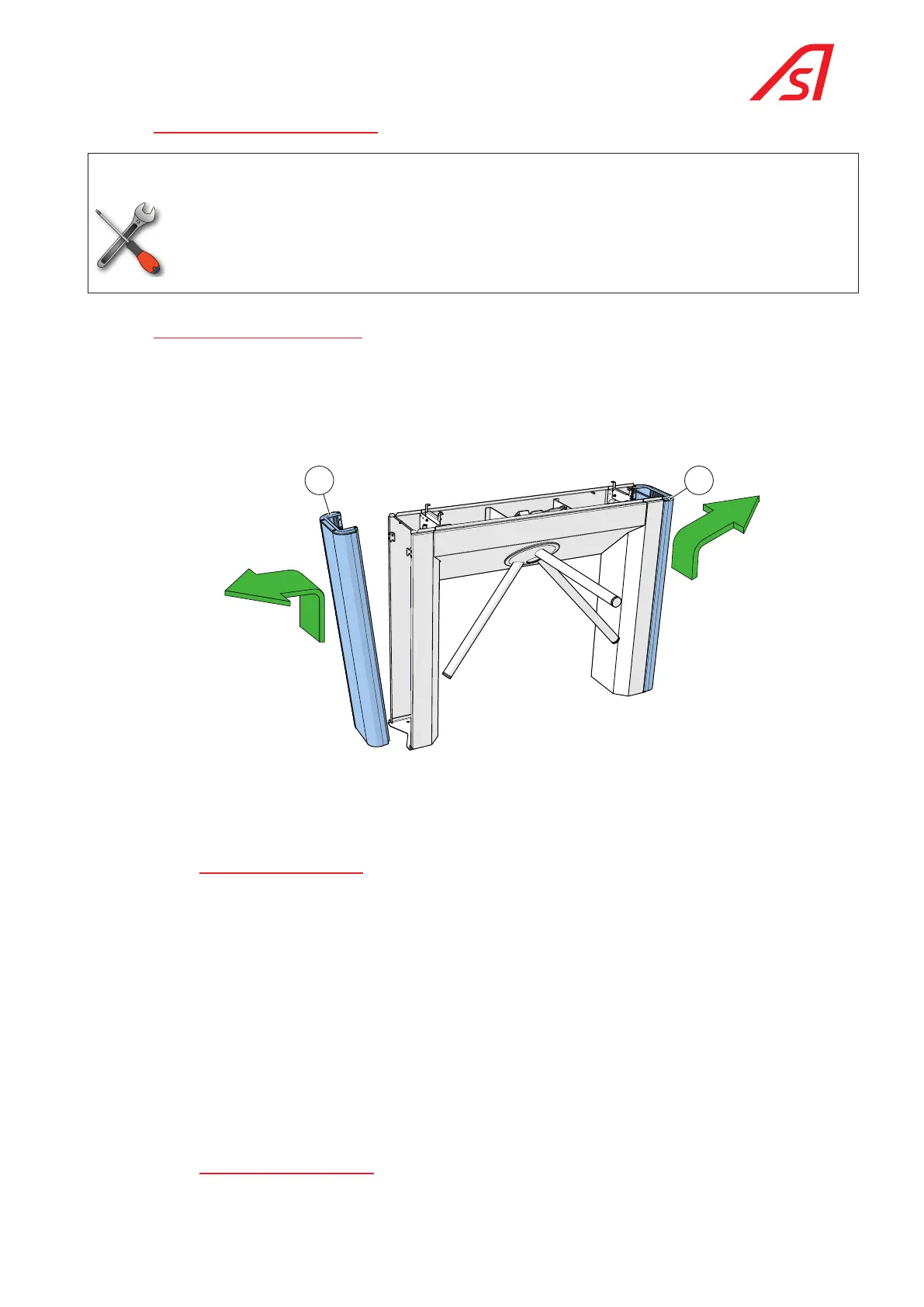

• Lift and remove the 2 feet (TL2) and the top cover (TL1).

4:3 4:2

Fig. 12 - Removing the feet (TL2)

• Check the condition of the material - although it has been carefully packed, damage may have occurred during

transport.

6.6.1. Site preparation Work

This is basically the following:

• Study the set-up and positioning of the equipment according to the general layout of the site.

• Prepare the holes in the floor according to the specifications of the installation drawing.

• Be sure to drill the holes with a diameter suitable for the expandable dowels that you are going to use (recommended

type: model B15/30, ref. -/3413/000).

• Check the correct location of the cable passage according to the installation drawing. .

• Prepare the passage for the electrical control cables of the Central Controller Station (not supplied) and the mains

supply cables (230V single-phase + earth, i.e. 3G x 2.5). Provide 1.5 metres extra.

If you add any elements to the feet of the turnstile that could ignite (see EN60950 standard, paragraph 4.4.5), ensure that

the installation surface is non-flammable.

6.6.2. inStalling the turnStile

• Position the turnstile precisely.

Loading...

Loading...