p. 40/46

TLxx-MT-EN-04

9.2.6. replacement of ringS, WaSherS, SpringS and other Wear partS

After a few million operations, some rings, washers and springs may show signs of wear; their replacement does not

pose any particular problem. In the event of wear, Automatic Systems suggests replacing certain sub-assemblies

containing several wear parts at the same time. For example:

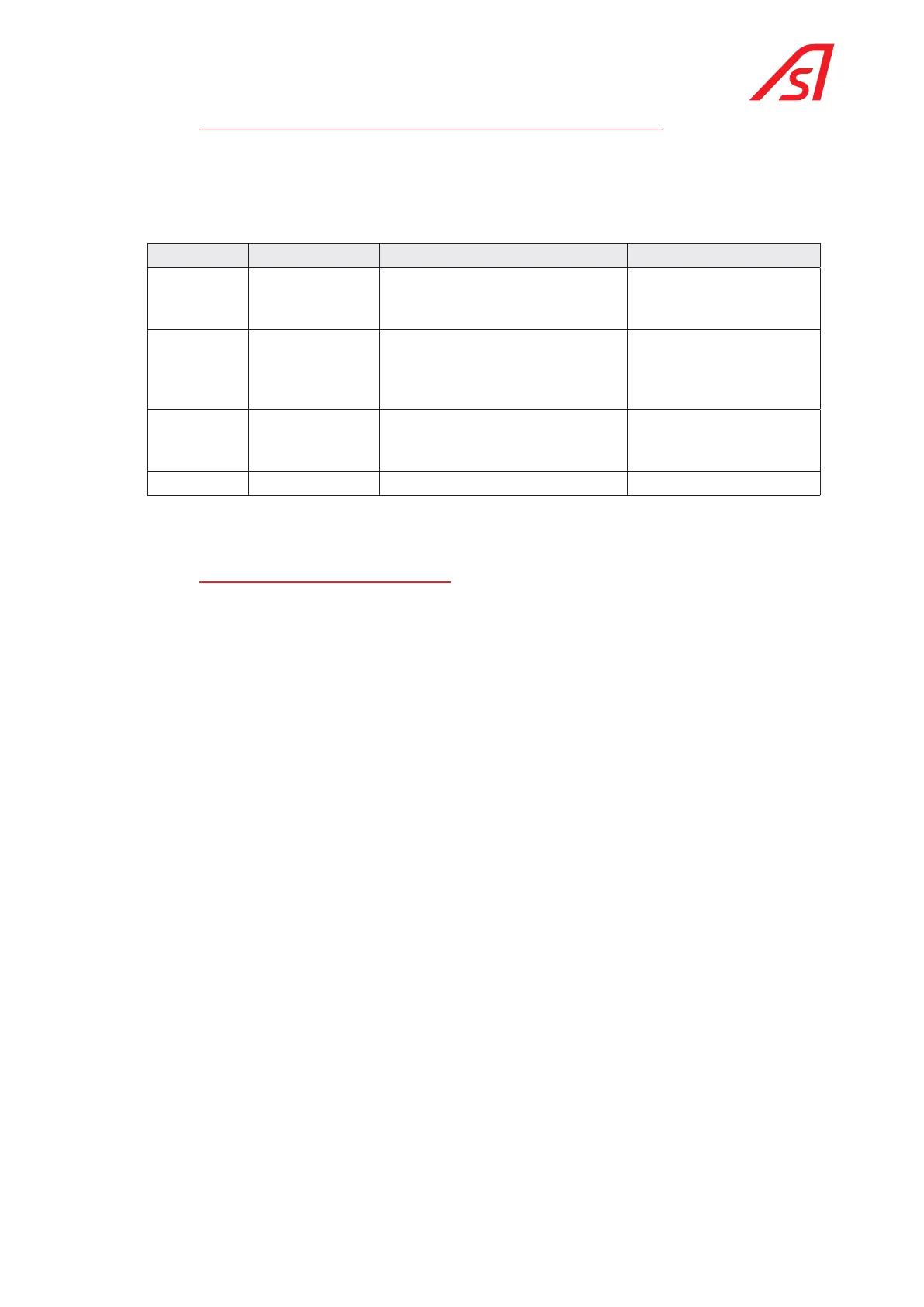

Reference Article code Description Comment

1 AEM-E-0010960 Centring assembly Contains the fixing block,

stop, two compression

springs and bearings.

2 AME-E-0010983 Shock absorber assembly (option) Contains the shock

absorber and the

movement transmission

system with its support.

3 AEM-E-0011574 Dropping-arm actuator assembly Contains the suction

cup, bracket, pads and 4

springs.

4 E/7002/914 Electro-magnet assembly With support,

To obtain access to these sub-assemblies, remove the upper frame CHS-E18495 (4x M10 bolts and 2x M6 bolts near

the upper bearing).

9.2.7. replacing a functional pictogram

Functional pictograms are glued to the SUP-E20471 support fixed into the upper part of the uprights of the central

frame.

• Remove the cover

• Disconnect the power supply (main circuit breaker)

• Disconnect the functional pictogram cable

• Remove the defective circuit from its support ( glued with a double face tape)

• Insert the replacement pictogram, connect the cable and switch on again.

Loading...

Loading...