Product overview

14 ─── Version: 2.1AS2000

3.2

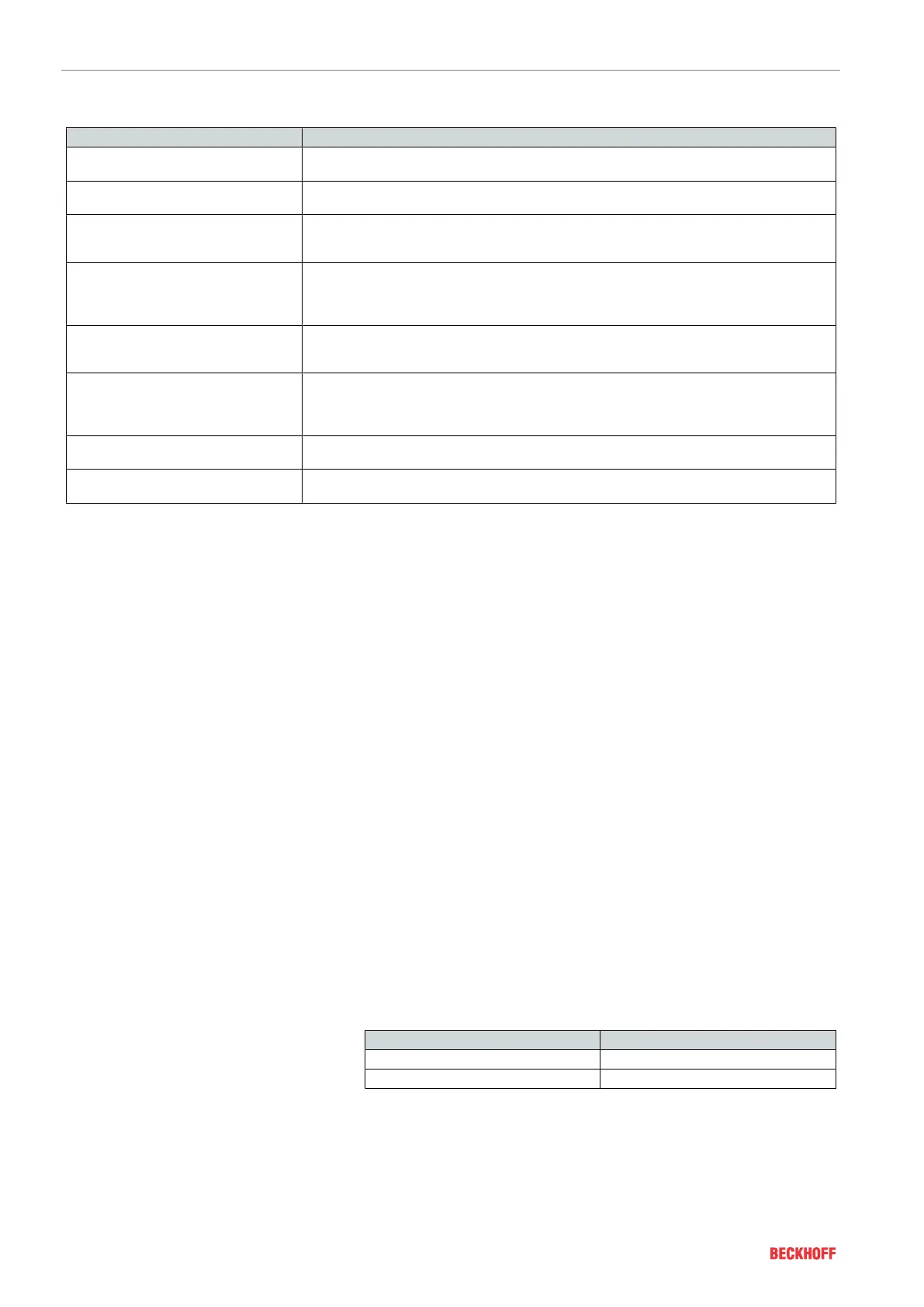

Type key

AS 20 uv – w x y z Explanation

AS Product area

Stepper motors

20 Series

AS2000

u Flange size

2 = N2, 56mm

4 = N3, 86mm

v Overall length

1 = One stack

2 = Two stacks

3 = Three stacks

w Shaft versions

0 = Smooth shaft, for AS202x only

1 = Shaft with feather key, for AS204x only

x Winding type

C = 2A

H = 5A … 6A

J = < 8A

y Feedback system

1 = Encoder 24V

DC

, 1024 increments

z Holding brake

0 = Without holding brake

Product characteristics

Standardized NEMA flange sizes

Adaptation to international standards through flange sizes N2,

NEMA23 and N3, NEMA34.

Step angle and power range

The power gap to the AM8000 synchronous servomotor is consider-

ably reduced through a step angle of 1.8°.

High protection class

The IP54 protection class protects the stepper motors against

splash water, contact and dust.

Extended features

• Integrated M12 power connector and feedback socket

• Integrated torsion-proof encoder, 1024 inc/rev, for closed-loop

control

By means of the field-oriented control, resonances are significantly

decreased and the development of heat and noise on the motor is

reduced.

Stepper motor terminals and stepper motor modules

All motors from the AS2000 series are to be put into operation with

Beckhoff motor terminals and modules for stepper motors. For fur-

ther details at chapter "Electrical installation", [Page45].

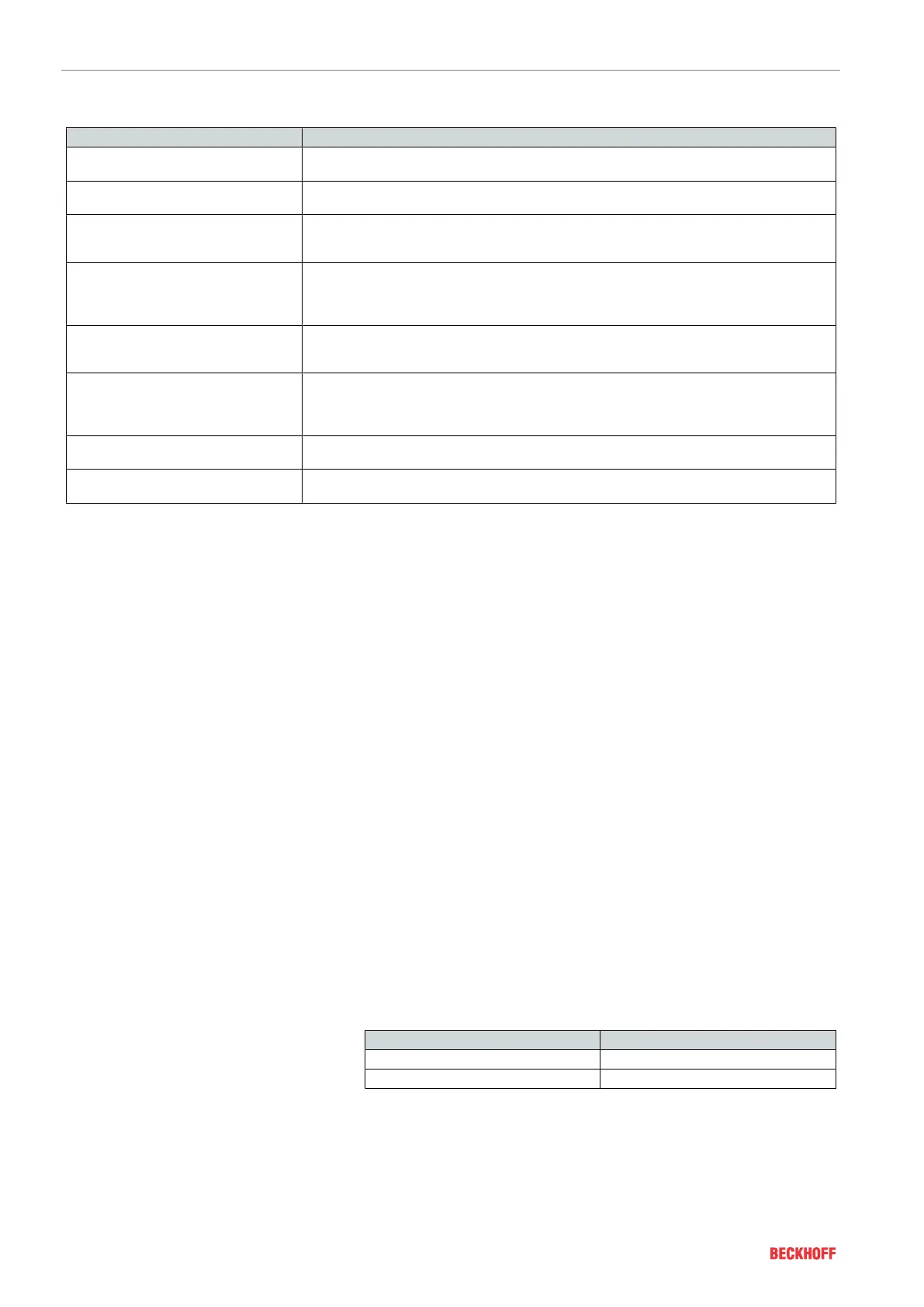

Ordering options and accessories

Flange size Product characteristic

2 = N2 Smooth shaft

4 = N3 Shaft with feather key

Preassembled cables for power and feedback are also available as

accessories.

Further accessories:

• Low-backlash planetary gear from the AG2250 series

• Elastomer couplings AX2090-+ECxx

Loading...

Loading...