Mechanical installation

Version: 2.1 ─── 43AS2000

Elastomer coupling [+]

Beckhoff elastomer coupling – operating instructions

The following chapter contains the most important information for

the mechanical installation of the Beckhoff elastomer coupling. For

further information, read the entire operating instructions for the

elastomer coupling.

Preparation

Use TPU-compatible lubricants

Do not use lubricating pastes, other high-pressure additives or oils

and greases containing molybdenum disulphide. Use Vaseline, for

example.

The use of unsuitable lubricants can lead to incompatibility with

the elastomer ring and impair the functionality.

Facilitated assembly

The bores in the coupling hub have an H7 fit.

Beckhoff recommends play of 0.1 – 0.5 mm between the coupling

hub and the shaft. The fitting tolerance and the oiling of the shaft

journals simplify the assembly and disassembly of the coupling.

Check the shaft connection dimensions and the tolerances. Make

sure that the shafts to be connected and bores in the hub are clean

and free from burrs. Adhere to the fitting tolerance and oil the shaft

journals prior to assembly.

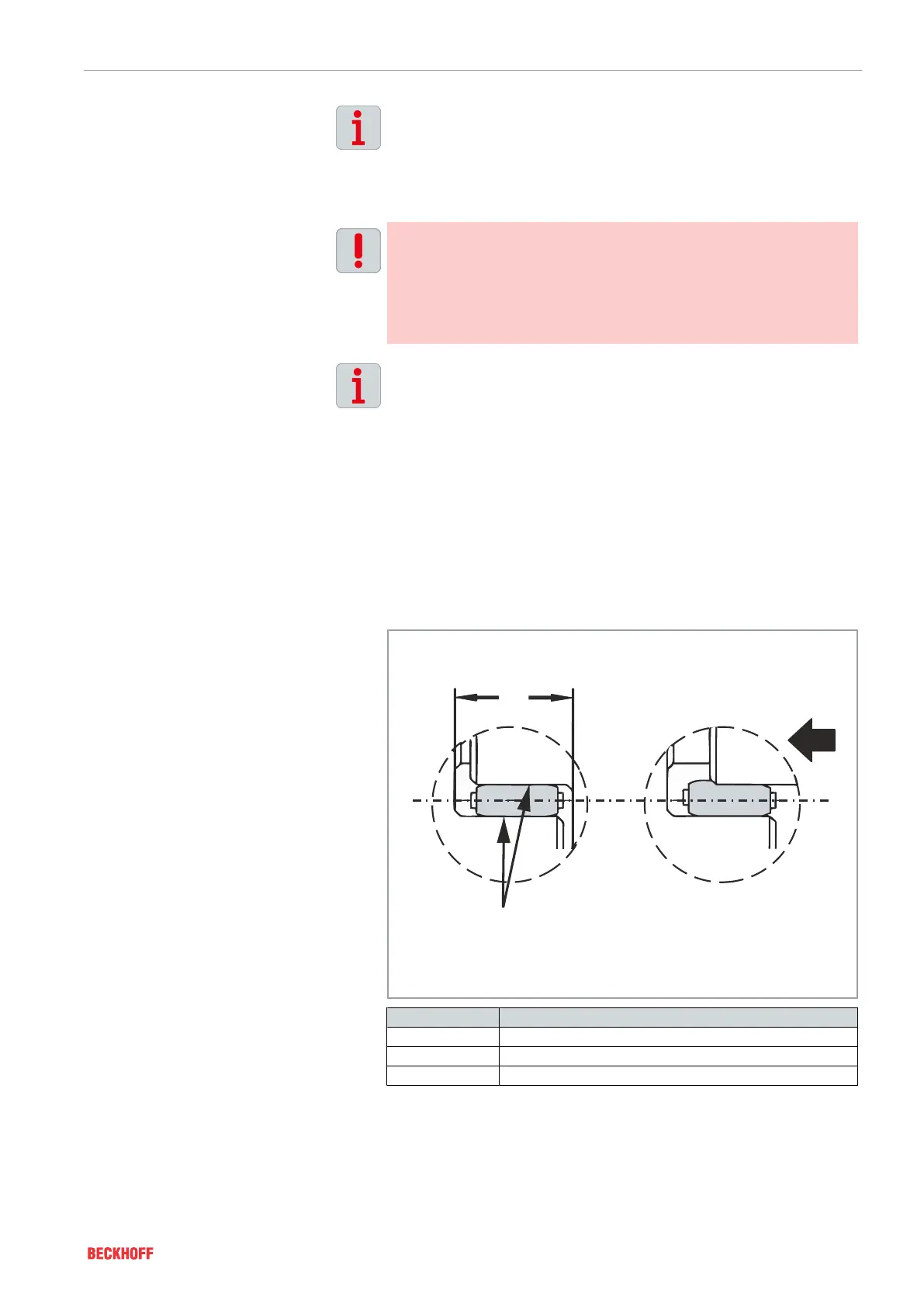

When pushing the coupling hubs together, the compressive pre-

stressing of the elastomer ring requires an axial mounting force. The

axial force can be reduced after cleaning the elastomer ring and by

lightly oiling the contact surfaces.

Number Meaning

1 Spacing distance, see Technical data

2 Axial mounting force

3 Contact surfaces

Loading...

Loading...