Mechanical installation

40 ─── Version: 2.1AS2000

Mechanical installation

Perform all work with the greatest care and without hurrying.

Flange mounting

The following table provides information on components for mount-

ing the motor on the machine / system:

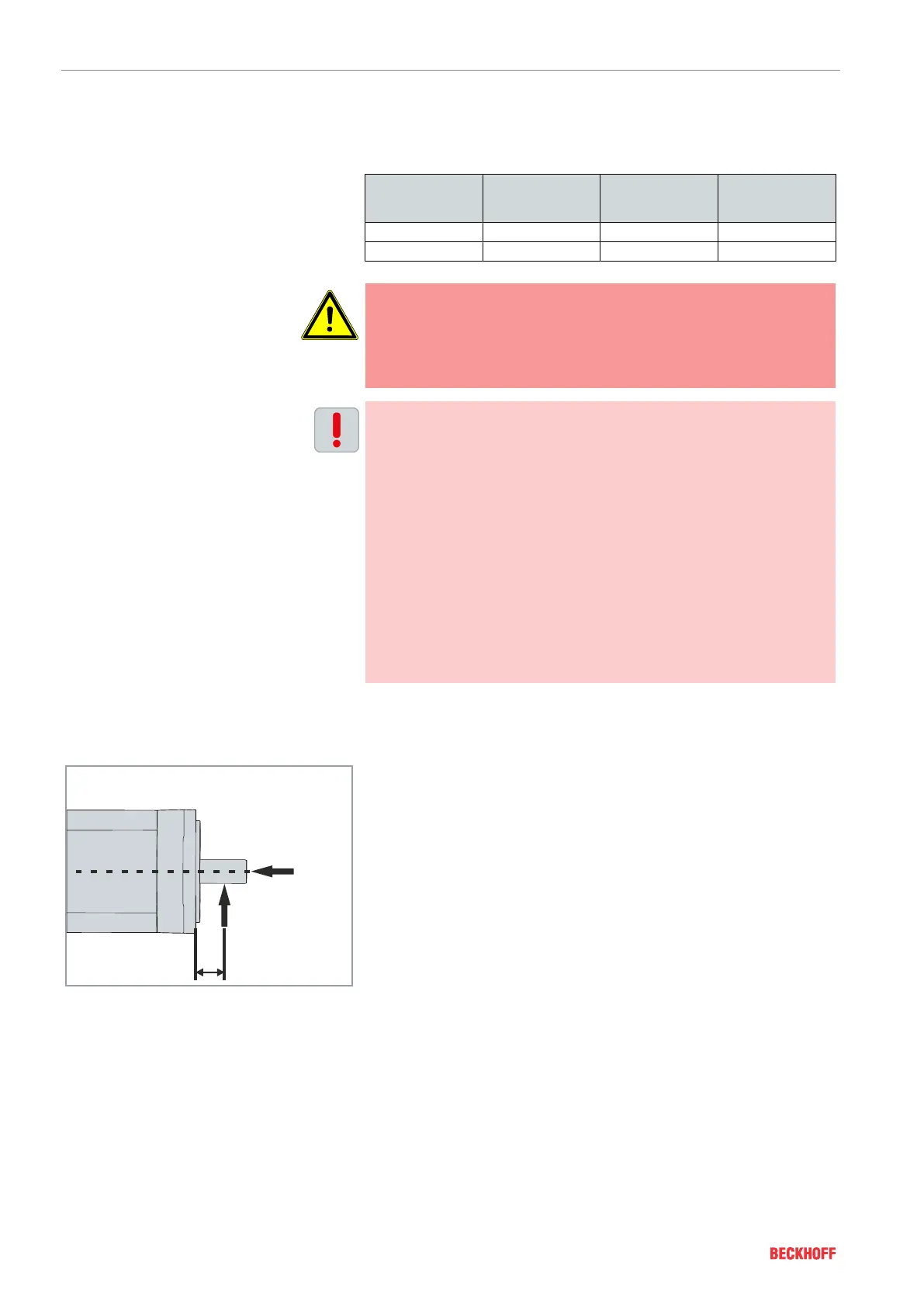

Motor Bore dia. [mm] Cheese-head

screw DIN EN ISO

4762, 8.8

Tightening torque

[Nm]

AM202x 4.5 M4 3

AM204x 5.6 M5 6

Output elements

Secure moving parts against ejection

Make sure there are no moving parts on or in the machine during

operation. Feather keys [+] are only secured during transport.

Unsecured parts can be ejected from the machine during opera-

tion and cause serious or fatal injuries.

Protect the motor from inadmissible load

Avoid bending components during transport or handling and do

not change any insulation distances. Avoid hard shocks to the

shaft end, the ball bearings or the feedback system. Furthermore,

note vibration qualities and vibration resistance. If necessary, pro-

vide additional support for the motor.

An impermissible load on the components can have a negative ef-

fect on the performance of the motor. Impacts on the motor shaft

impair the concentricity of the motor.

Ensure adequate earthing via the protective conductor

The thermal connection of the motor flange determines the power

loss.

Ensure adequate earthing via the protective conductor or the mo-

tor flange.

Bearing load during instal-

lation

Avoid mechanically overdetermined support of the motor shaft

through rigid coupling and additional external support.

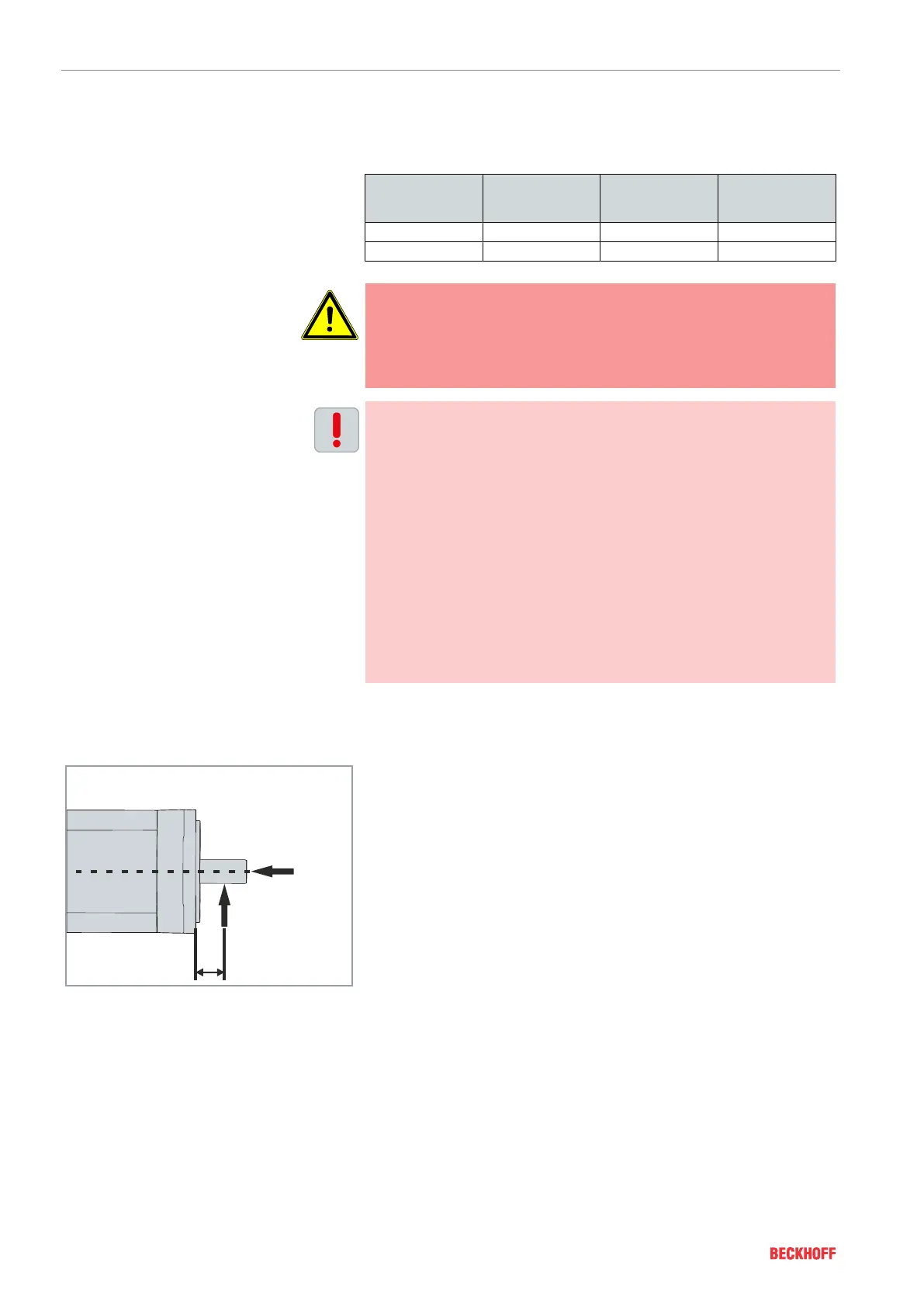

When mounting output elements, care must be taken that the load

on the shaft and bearings due to shear forces, such as radial force

F

R

and axial force F

A

, is low. Axial loads shorten the service life and

can lead to malfunctions of the holding brake [+].

Special features when using toothed belt drives:

The radial loads on the shaft must not be exceeded when using a

toothed belt drive. The motor shaft may suffer a fatigue fracture due

to excessive alternating loads. Please pay attention to chapter:

"Technical data", [Page16].

Loading...

Loading...