18

NOTE: The gasketing of the unit to the roof curb is critical for a

watertight seal. Install gasket supplied with the roof curb as shown

in Fig. 16-18. Improperly applied gasket can also result in air leaks

and poor unit performance.

ALTERNATE UNIT SUPPORT (IN LIEU OF CURB OR

SLAB MOUNT)

A non-combustible sleeper rail can be used in the unit curb sup-

port area. If sleeper rails cannot be used, support the long sides of

the unit with a minimum of 4 equally spaced 4-in. x 4-in. (102 mm

x 102 mm) pads on each side. Locate pads so that they support the

rails. Make sure to avoid the fork openings.

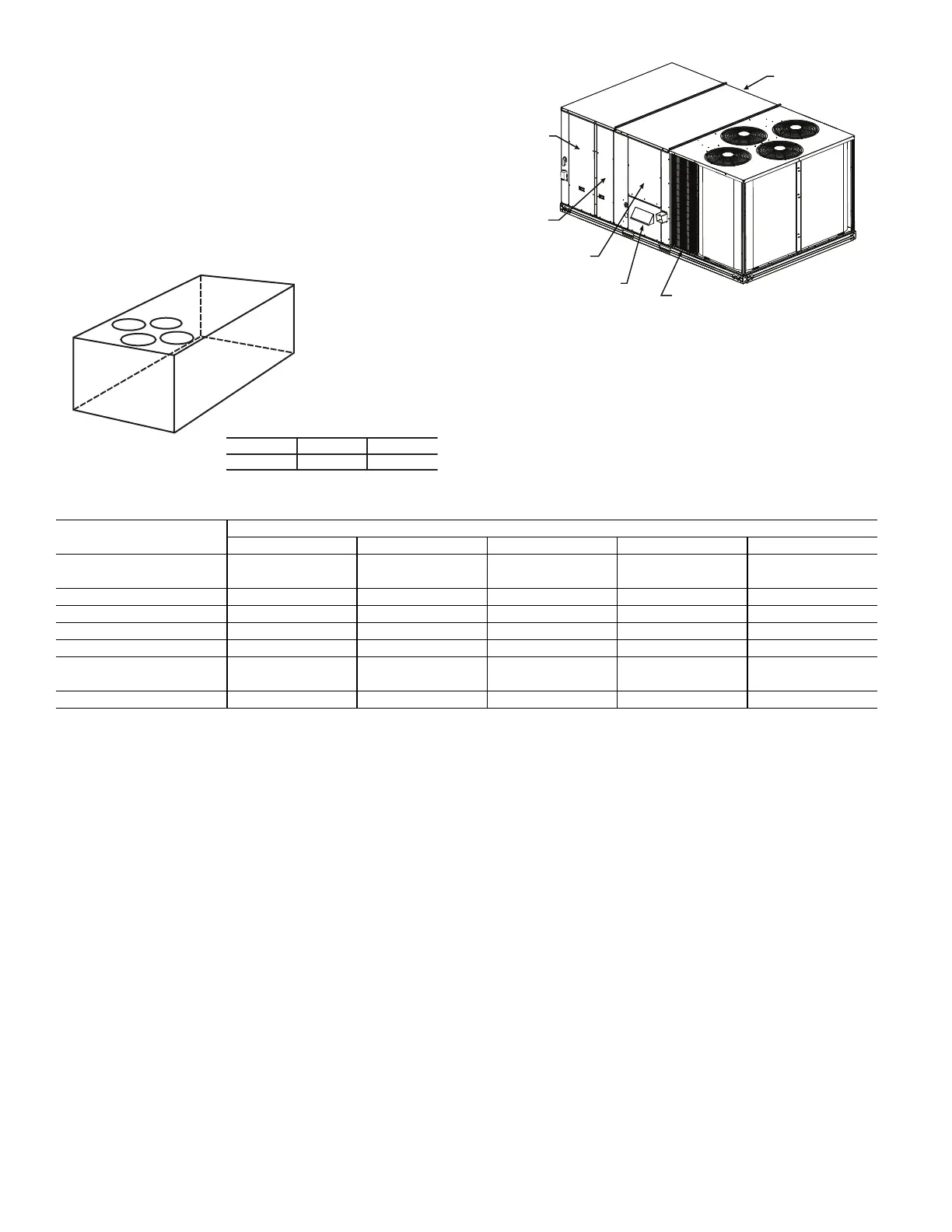

Fig. 14 — Unit Leveling Tolerances

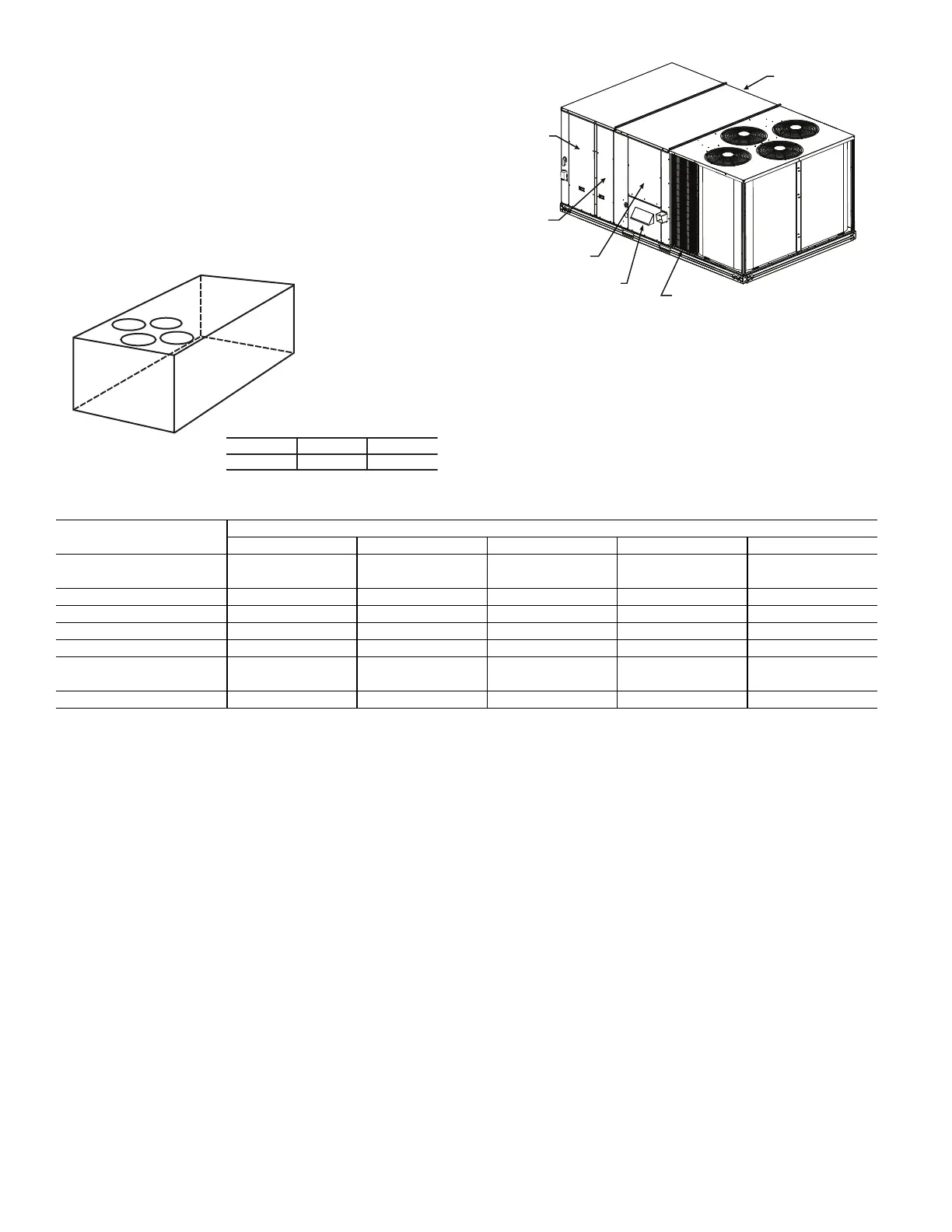

Fig. 15 — Typical Access Panel and Compressor

Locations

Table 2 — Operating Weights

A-B

0.25 (6)

B-C

0.5 (12)

A-C

0.5 (12)

MAXIMUM ALLOWABLE

DIFFERENCE IN. (MM)

A

B

C

CONTROL BOX

ACCESS PANEL

FILTER AND

INDOOR COIL

ACCESS PANEL

INDOOR BLOWER

ACCESS PANEL

GAS HEAT

ACCESS PANEL

COMPRESSOR

(EACH SIDE)

HOOD CARTON LOCATION

(REAR ACCESS PANEL)

48TC

UNITS — lb (kg)

17 20 24 28 30

Base Unit

Novation

®

Coil 1824 (829) 1839 (836) 1989 (904) 2118 (963) N/A

RTPF Coil 1907 (867) 1922 (874) 2072 (942) 2197 (999) 2640 (1200)

Economizer 246 (112) 246 (112) 246 (112) 246 (112) 246 (112)

Powered Outlet 35 (16) 35 (16) 35 (16) 35 (16) 35 (16)

Humidi-MiZer

®

System 110 (50) 110 (50) 120 (54) 120 (54) N/A

Curb

14-in. (356 mm) 240 (109) 240 (109) 255 (116) 255 (116) 255 (116)

24-in. (610 mm) 340 (154) 340 (154) 355 (161) 355 (161) 355 (161)

Loading...

Loading...