22

Step 5 — Field Fabricate Ductwork

Cabinet return-air static pressure (a negative condition) shall not

exceed 0.5 in. wg (87 Pa) with economizer or without economizer.

For vertical ducted applications, secure all ducts to roof curb and

building structure. Do not connect ductwork to unit.

Fabricate supply ductwork so that the cross sectional dimensions

are equal to or greater than the unit supply duct opening dimen-

sions for the first 18-in. (458 mm) of duct length from the unit

basepan.

Insulate and weatherproof all external ductwork, joints, and roof

openings with counter flashing and mastic in accordance with ap-

plicable codes.

Ducts passing through unconditioned spaces must be insulated

and covered with a vapor barrier.

If a plenum return is used on a vertical unit, the return should be

ducted through the roof deck to comply with applicable fire codes.

A minimum clearance is not required around ductwork.

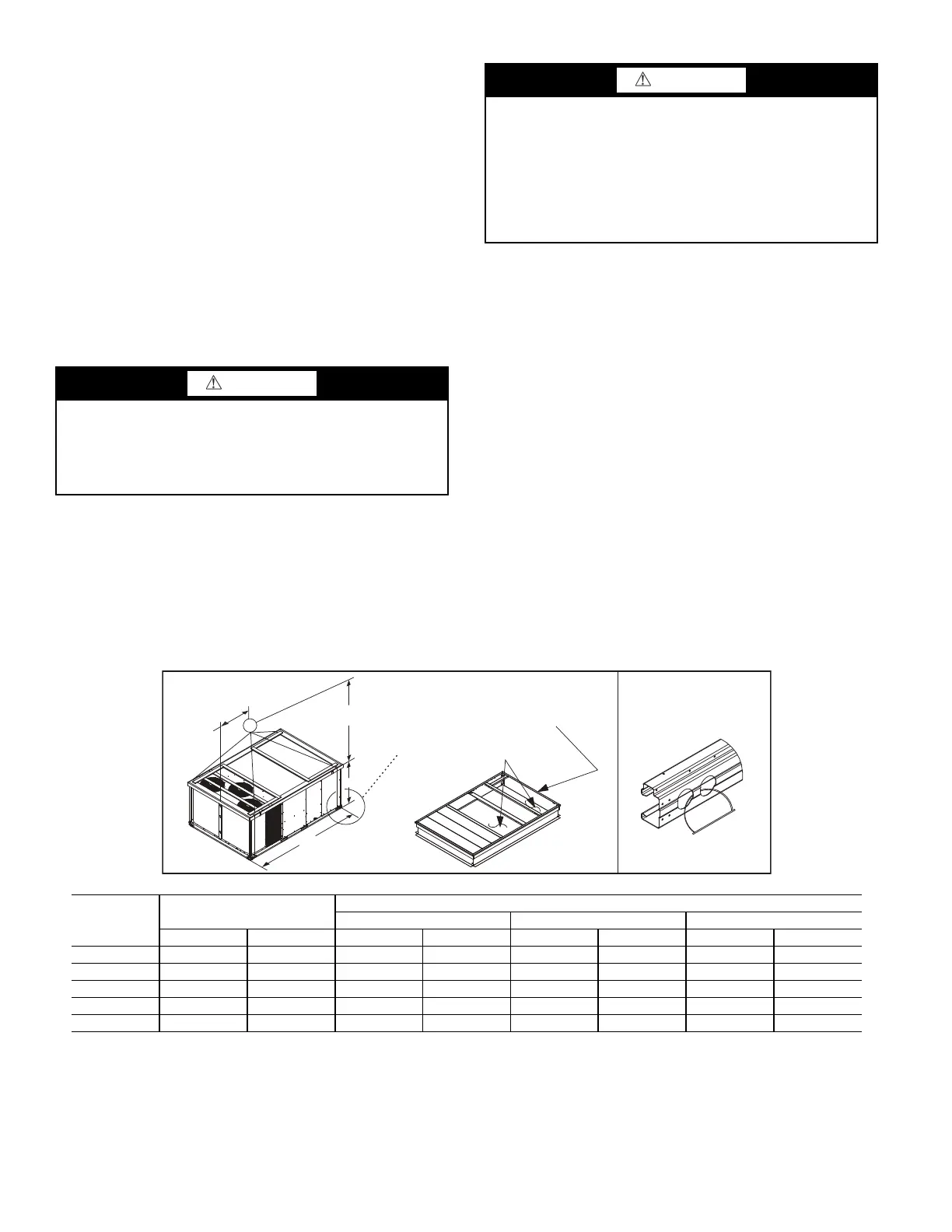

Step 6 — Rig and Place Unit

Keep unit upright and do not drop. Spreader bars are not required

if top crating is left on the unit. Rollers may be used to move unit

across a roof. Level by using unit frame as a reference. See Table 2

and Fig. 19 for additional information.

Lifting holes are provided in base rails as shown in Fig. 19. Refer

to rigging instructions on the unit.

Before setting the unit onto the curb, recheck gasketing on curb.

POSITIONING ON CURB

Position unit on roof curb so that the following clearances are

maintained:

1

/

4

-in. (6 mm) clearance between the roof curb and the

base rail inside the right and left,

1

/

2

-in. (12 mm) clearance be-

tween the roof curb and the base rail inside the front and back.

This will result in the distance between the roof curb and the base

rail inside on the condenser end of the unit being approximately

equal to Details A and B in Fig. 16-18.

Do not attempt to slide unit on curb after unit is set. Doing so will

result in damage to the roof curb seal.

Although unit is weatherproof, guard against water from higher

level runoff and overhangs.

Flue vent discharge must have a minimum horizontal clearance of

48-in. (1220 mm) from electric and gas meters, gas regulators, and

gas relief equipment. Minimum distance between unit and other

electrically live parts is 48-in. (1220 mm).

Flue gas can deteriorate building materials. Orient unit such that

flue gas will not affect building materials. Locate mechanical draft

system flue assembly at least 48-in. (1220 mm) from an adjacent

building or combustible material.

After unit is in position, remove rigging skids and shipping

materials.

Fig. 19 — Rigging Details

CAUTION

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in damage to roofing

materials.

Membrane roofs can be cut by sharp sheet metal edges. Be

careful when placing any sheet metal parts on such roof.

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage.

All panels must be in place when rigging. Unit is not designed

for handling by fork truck when packaging is removed.

If using top crate as spreader bar, once unit is set, carefully

lower wooden crate off building roof top to ground. Ensure

that no people or obstructions are below prior to lowering the

crate.

NOTES:

1. Dimensions in ( ) are in inches.

2. Hook rigging shackles through holes in base rail, as shown in detail “A.” Holes in base rails are centered around the unit center of gravity.

3. Use wooden top skid, when rigging, to prevent rigging straps from damaging the unit.

UNIT

MAX WEIGHT

DIMENSIONS

ABC

LB KG in. mm in. mm in. mm

48TC**17 2355 1068 127.8 3249 58.7 1491 52.3 1328

48TC**20 2370 1075 127.8 3249 58.7 1491 52.3 1328

48TC**24 2516 1141 141.5 3595 71.5 1816 52.3 1328

48TC**28 2652 1203 141.5 3595 71.5 1816 60.3 1532

48TC**30 2976 1353 157.8 4007 80.3 2040 60.3 1532

B

C

A

(914-1371)

36"-54"

DETAIL A

SEE DETAIL A

PLACE ALL SEAL STRIPS

IN PLACE BEFORE PLACING

UNIT ON ROOF CURB.

DUCT END

Loading...

Loading...