Loading...

Loading...

Do you have a question about the Craftsman 113.197250 and is the answer not in the manual?

Details major hazards like kickback, wrong way feed, and thrown workpieces, with signal words.

Covers personal safety, work area safety, and general saw safety rules for safe operation.

Locates and explains safety labels on the radial arm saw for user awareness.

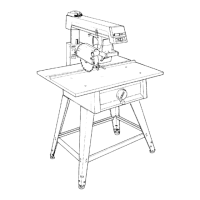

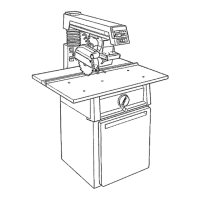

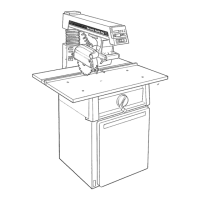

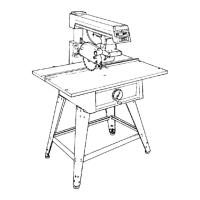

Instructions for unpacking, identifying parts for models 113.197210 and 113.197250.

Steps for attaching the handwheel and mounting the motor securely.

Detailed instructions for assembling the 23" cabinet or the leg set for the saw.

Procedure for securely mounting the saw assembly onto the cabinet or leg set.

Operation of the power switch, including safety precautions with the yellow key.

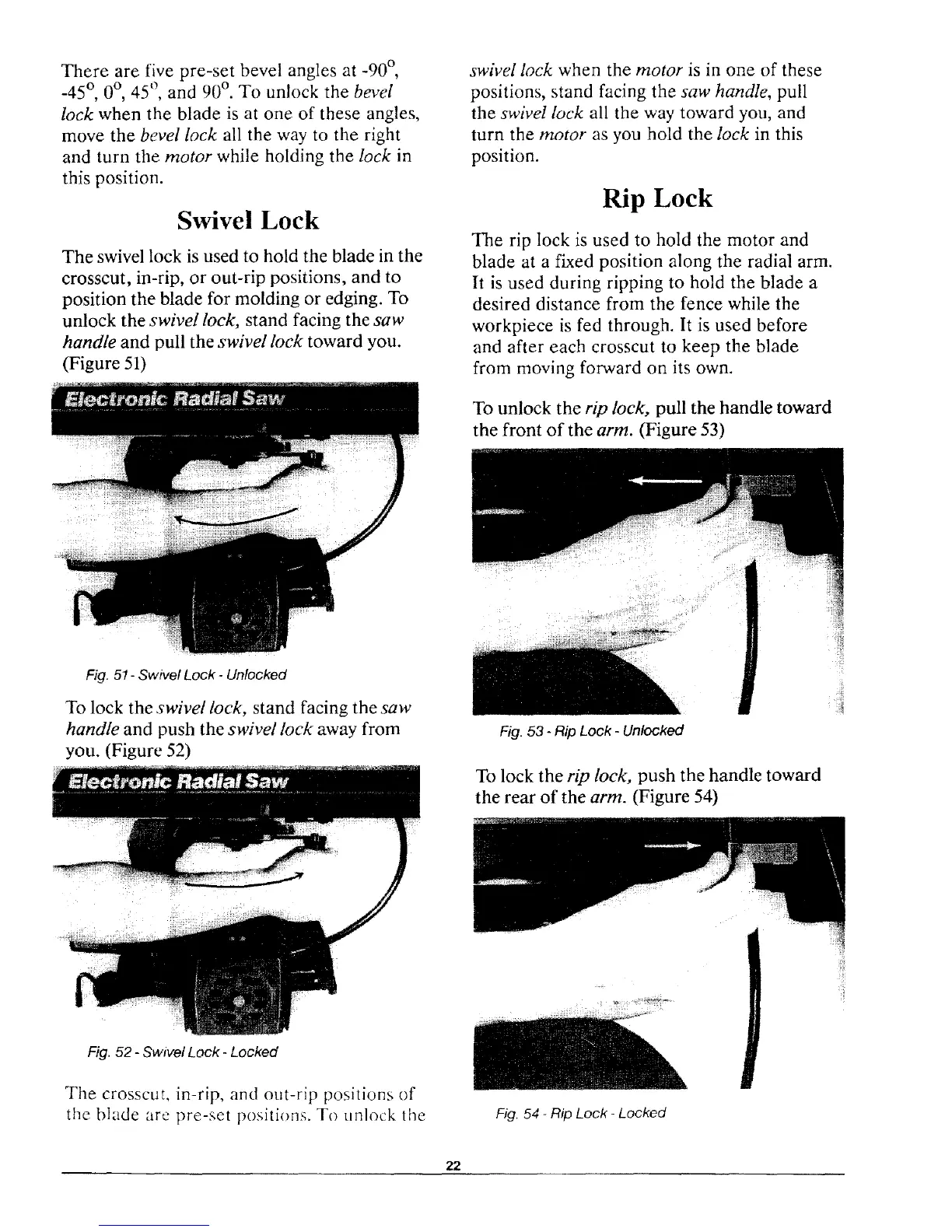

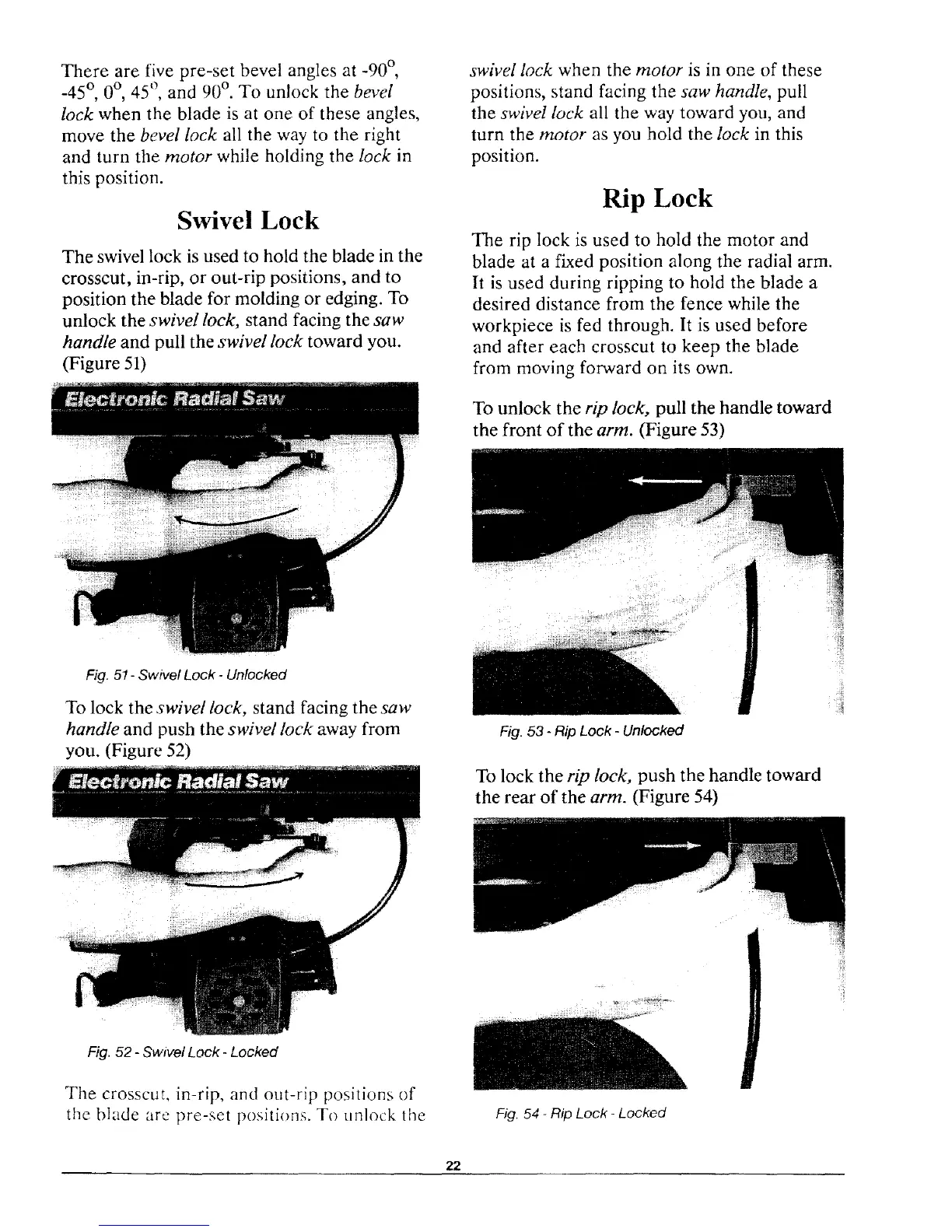

How to use and adjust locks for miter, bevel, and swivel positions for accurate cuts.

Explanation of digital display buttons (BEVEL, MITER, ELEV, RIP) and setting references.

Steps to ensure smooth arm movement and level table supports for accurate cuts.

Procedures for squaring the blade to the table and fence for precise crosscuts and rips.

Instructions for setting the blade parallel to the table for edging and preventing workpiece damage.

Overview of crosscut types and essential safety information for performing them.

Guidance on rip cuts, saw positions, workpiece handling, and safety precautions.

Information on using fences, push sticks, and auxiliary fences for various cutting tasks.

Procedures for cleaning, lubrication, and replacing parts to keep the saw in working order.

Guides for diagnosing and resolving problems with electronics, motor, and saw operations.

How to adjust bevel lock, swivel lock, miter lock, and rip lock for proper function.