Loading...

Loading...

Do you have a question about the Daikin RMXS-L Series and is the answer not in the manual?

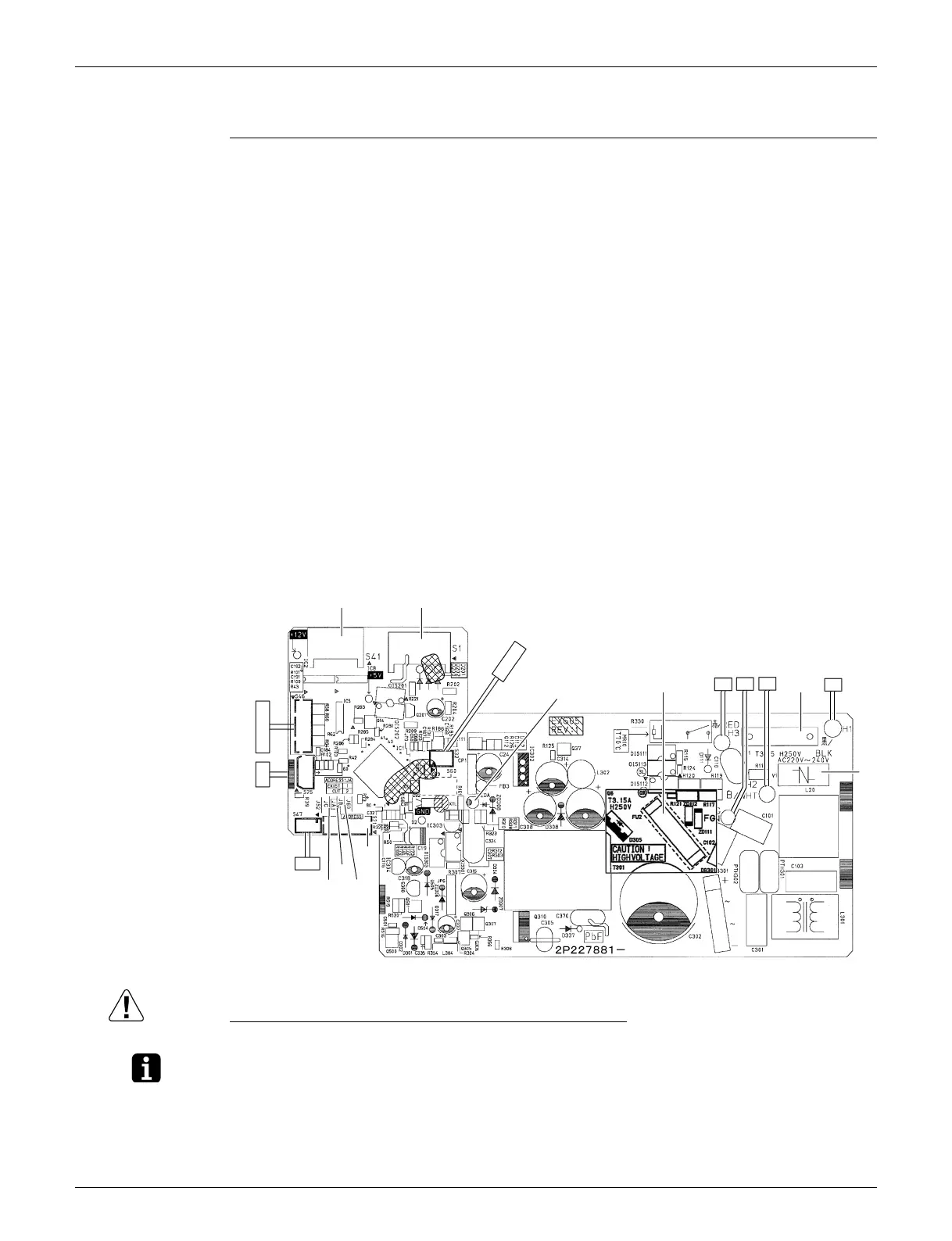

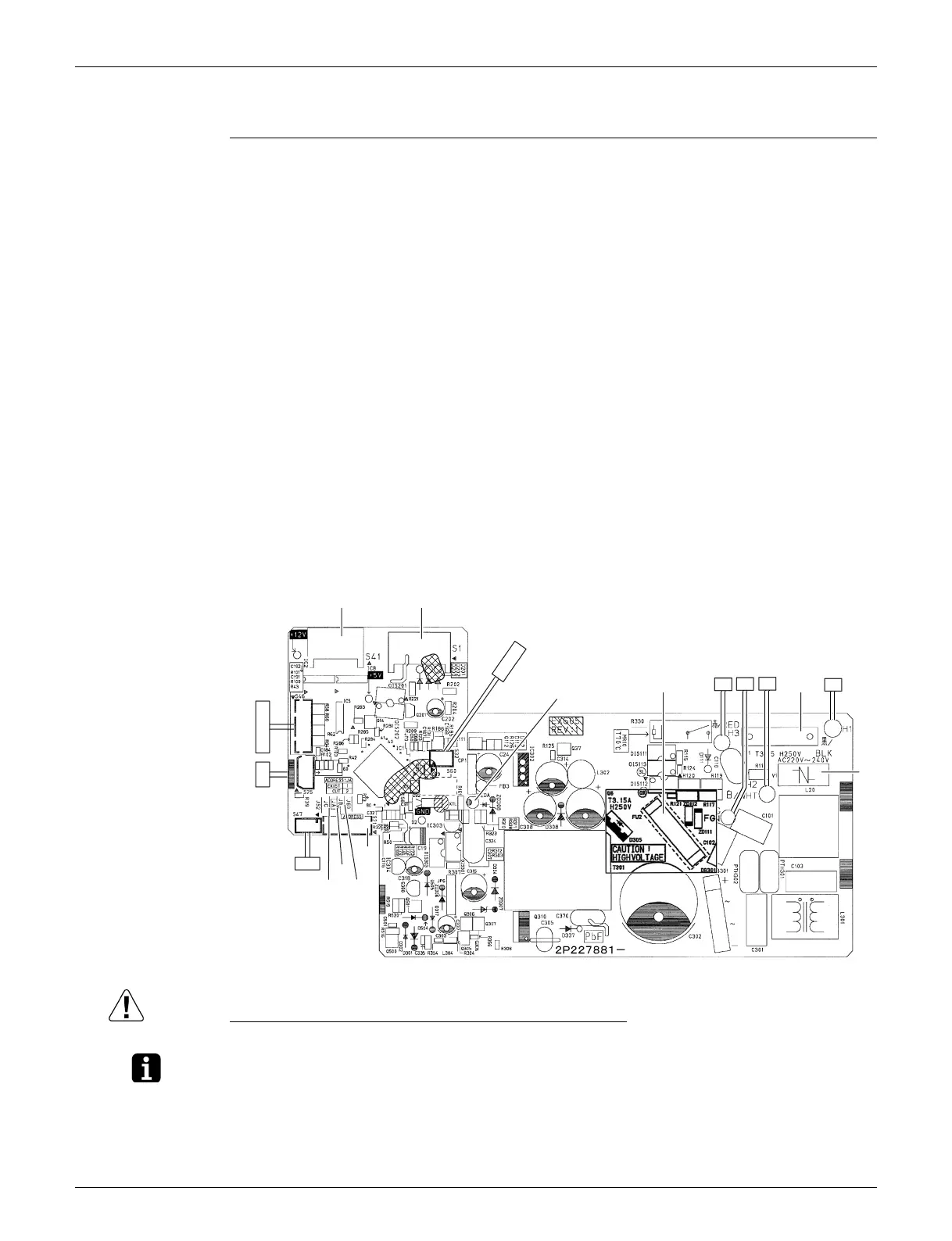

Provides detailed specifications for the outdoor unit, including capacity, dimensions, and electrical data.

Diagrams illustrating refrigerant flow during cooling, heating, and oil return operations.

Covers critical protection controls for high/low pressure, temperature, inverter, freeze-up, and condensation.

Provides procedures for initial test operation, including power checks and operation verification.

Details procedures for configuring field settings on outdoor units and remote controllers.

Guides troubleshooting using LED indicators on outdoor unit and service PCBs for error identification.

Outlines service diagnosis procedures for various indoor unit series using remote controllers and error codes.

Comprehensive list of error codes with descriptions and reference pages for troubleshooting specific issues.

Provides specific troubleshooting steps for errors found in CTXG, CTXS, FTXS, CDXS, FDXS, FVXS series.

Offers troubleshooting steps for errors specific to FFQ Series indoor units, covering PCB, motor, and sensor issues.

Details troubleshooting procedures for the Branch Provider (BP) unit, including expansion valve and PCB abnormalities.

Covers troubleshooting for outdoor unit issues like PCB abnormalities, sensors, compressor, and fan motor problems.