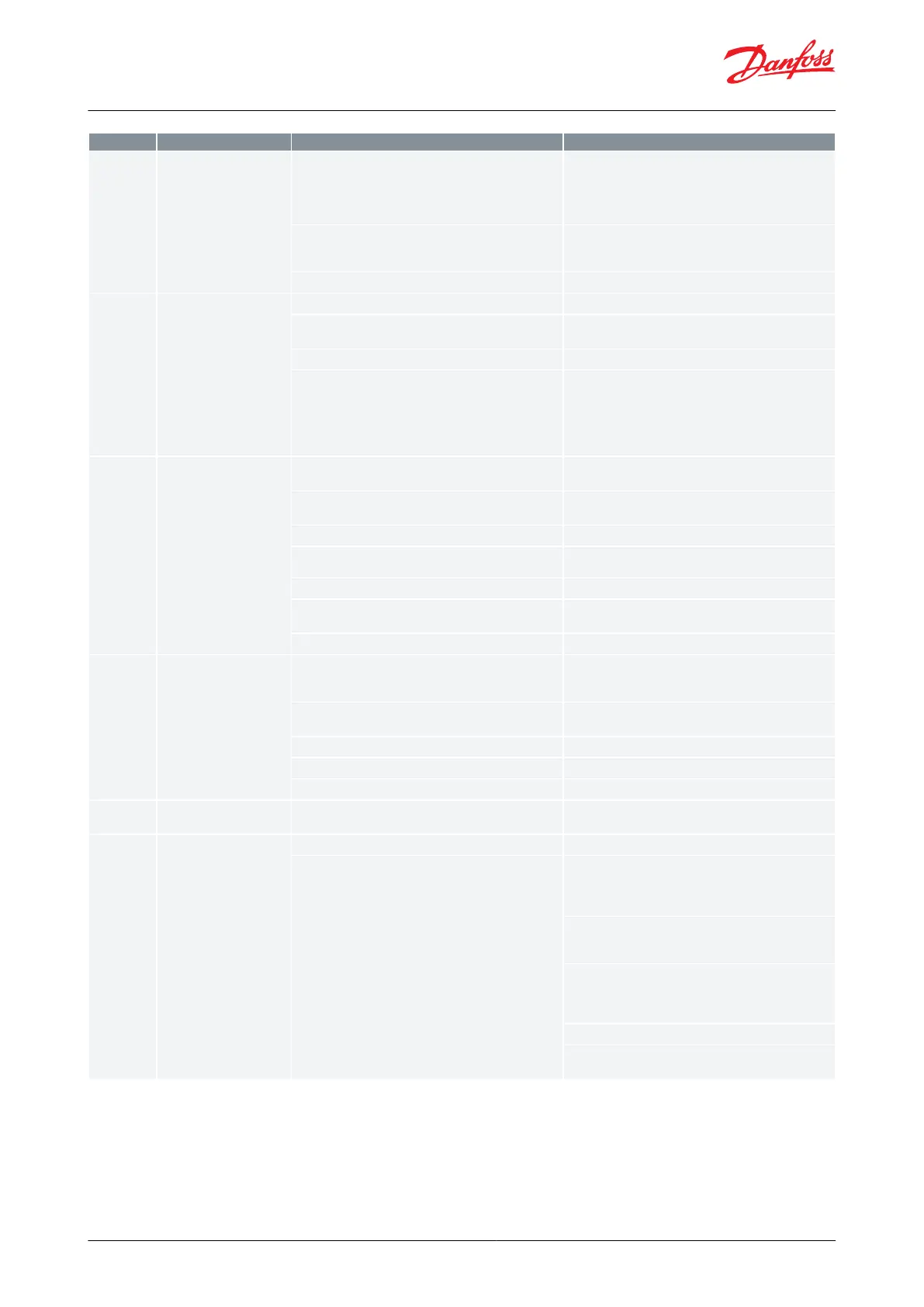

Loud refrigerant or undercharged refrigerant.

• Charge the system with appropriate refrigerant capaci-

ty.

• Check for leakage is the system.

• If the valve is placed much higher than condenser

tweet check pressure dierence.

Flash gas can lead to high SH or low suction pressure

• Use the right valve size.

• Also refer to section “High Superheat” and “Suction

pressure too low”

Pressure drops across lter.

• Check and replace the Stet.

Steppe valves open/ close

too slow

Incorrect selection of valve type.

• Dane the correct valve type.

Incorrect valve installation.

• Check the physical vale and cable and intake in light

way.

MOPD is higher than valve specication.

• Check the valve spec and choose the correct vane.

Check valve speed setting.

• Drive the stepper valve with the recommended Speed.

• Too high or too low speed could result in loss step in

the valve.

• For the user dened valves, check the other valve set-

tings such as current, duty cycle, holding current and

other relevant parameter.

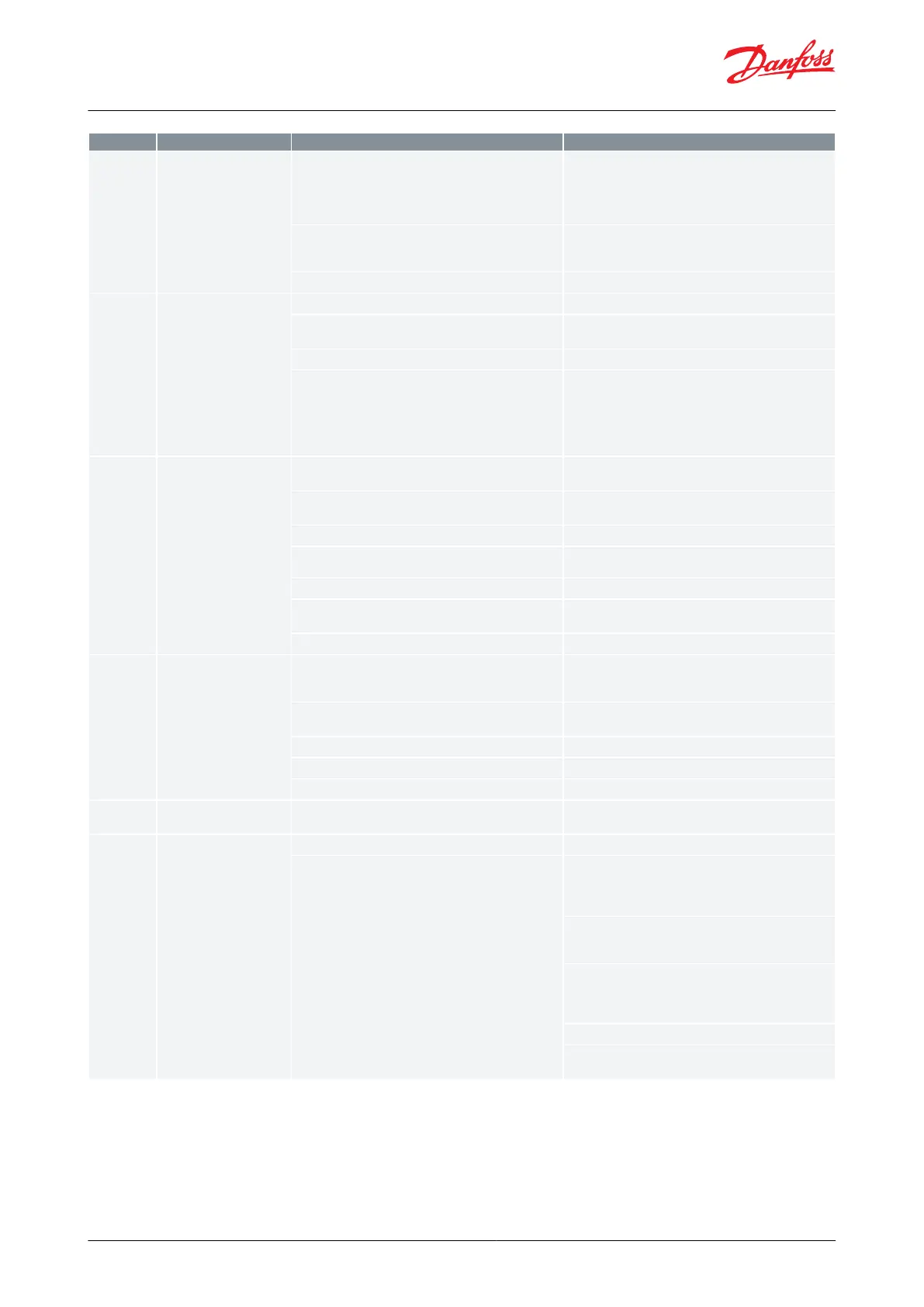

Opening degree of valve at

maximum OD for longer

time period

Lack of cooling capacity.

• Check the cooling capacity in the system Also check

section, expansion valve too small

The condenser pressure is too low.

• Check the ambient temperature.

• Adjust the condenser controller.

The lter drier is blocked by dirt

• Replacement Filter drier.

Flash gas in liquid line due to loss of refrigerant or under-

charge of refrigerant.

• Check section ash gas.

• Check valor setting matching installed valve.

Pressure transmitter is wrongly dened.

• Oita pressure range and correct pressure transmitter

type.

Wrong refrigerant selected

• Choose the correct refrigerant in the controller.

Hunting or uctuation valve

position

Too high gain (Kp and KpTe) or too low integration time

(Tn).

• Decrease Kp by factor of 1.5%

• Increase Tn 25% of the set value.

• Perform 1 and 2 in loop if needed.

• Check mounting of S2 sensor, Check the installation

guide section temperature sensor mounting.

Fluctuating Al signal for SH reference.

• Check Al signal quality.

Fluctuating pressure signal.

• Check section Fluctuating pressure signal.

• Check section Fluctuating Superheat.

Unstable OD on driving the

valve in Valve driver mode

• Check the Al signal quality.

• Use the Valve neutral zone feature.

Internal Leakage in the valve

Wrong selection of the valve.

• Check the valve type and its setting.

Step loss in stepper motor valve.

• Power cycle the controller.

• Enable the step loss feature i.e. overdriving. choose the

recommended overdrive value with respect to the in-

stalled valve.

• Drive the stepper valve with the recommended speed.

• Too high or too low speed could result in loss step in

the valve.

• Longer cables mounted than specied for the control-

ler.

• Separate Valve cable from other high-power cables and

do not bundle the cables.

• Blockage in the valve or high friction in the valve.

• MOM, exceeded than specied in the valve specica-

tion.

© Danfoss | Climate Solutions | 2022.06 BC398828796060en-000101 | 79

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Loading...

Loading...