Required tools

The service procedures described in this manual can be performed using common mechanic’s hand

tools. Special tools, if required are shown. Calibrate pressure gauges frequently to ensure accuracy. Use

snubbers to protect gauges.

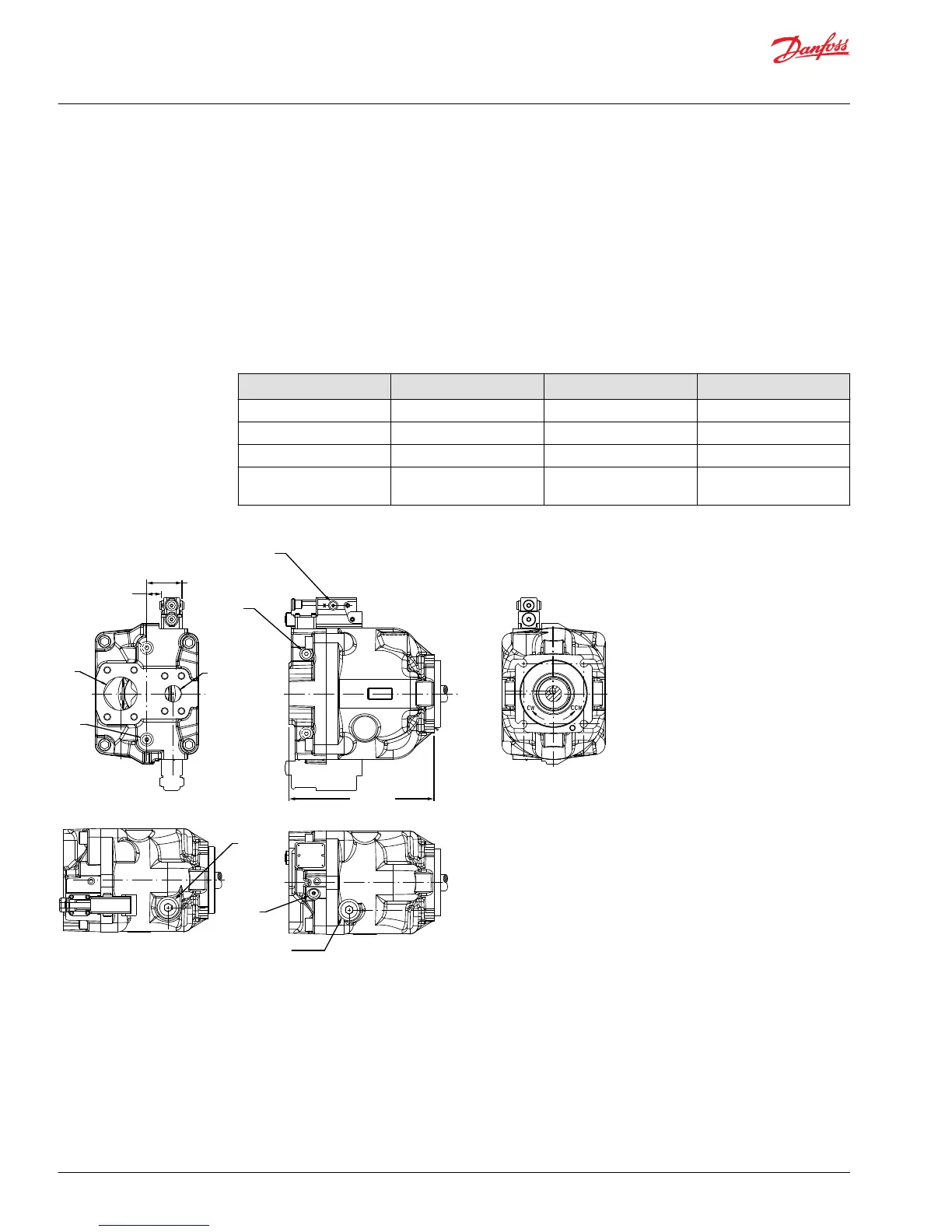

Port locations and gauge installation

The illustration below shows gauge port locations. Recommended pressure gauges and fittings are in the

table.

Gauge and port information

Port Purpose Range of gauge Fitting

M1, M2 System pressure 0-300 bar [0-5000 psi] 9/16 - 18 O-ring fitting

M4 Servo pressure 0-300 bar [0-5000 psi] 9/16 - 18 O-ring fitting

L1, L2 Case drain 0-300 bar [0-5000 psi] 1-1/16 - 12 O-ring fitting

X1 LS signal 0-300 bar [0-5000 psi] 7/16 - 20 O-ring fitting (tee

into LS signal line)

Gauge port locations

L1

X

M4

X

B

X

S

M2

S & B

L2

M1

Legend

B = Main pressure line

S = Suction line

L1, L2 = Case drain lines

X = Load sensing pressure port

M1 = CW endcap system pressure gauge*

M2 = Gauge port for port B*

M4 = Gauge port — servo pressure

*Same pressure

P104 052

Loading...

Loading...