VLT

®

5000 FLUX

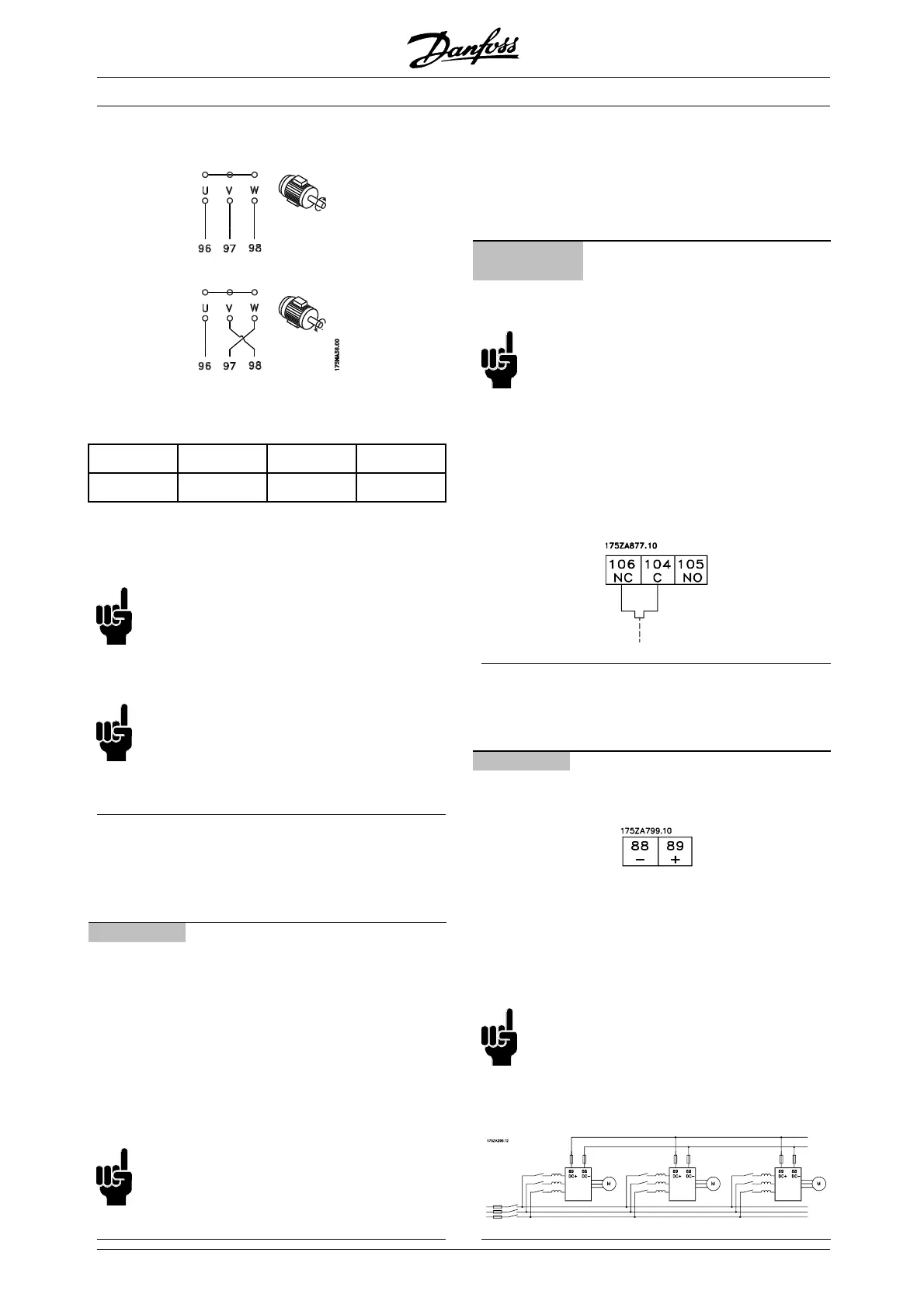

■ Motor shaft direction

The factory setting is for clockwise rotation with the

frequency converter output connected as follows:

CW U ⇒ 96 V ⇒ 97 W ⇒ 98

CCW U ⇒ 96 V ⇒ 98 W ⇒ 97

The direction of rotation can be changed by switching

two phases in the motor cable.

NB!:

If the application is running in closed loop with

an encoder as feedback signal, the encoder

signal A,A/B,B/ wires must be swopped or the

encoder direction must be changed in parameter 351.

NB!:

Flux vector drives can operate with one

motor only. It is not possible to run

parallel-connected motors on the output

side of the frequency converter.

■ Electrical installation - brake cable

(Only standard with brake and extended with

brake. Typecode: SB, EB, DE, PB).

No. Function

81, 82 Brake resistor terminals

The connection cable to the brake resistor must be

screened. Connect the screen by means of cable

clamps to the conductive back plate at the frequency

converter and to the metal cabinet of the brake resistor.

Size the brake cable cross-section to match

the brake torque. See also Brake instructions,

MI.90.FX.YY and MI.50.SX.YY for further information

regarding safe installation.

NB!:

Please note that voltages up to 960 V DC,

depending on the supply voltage, may

occur on the terminals.

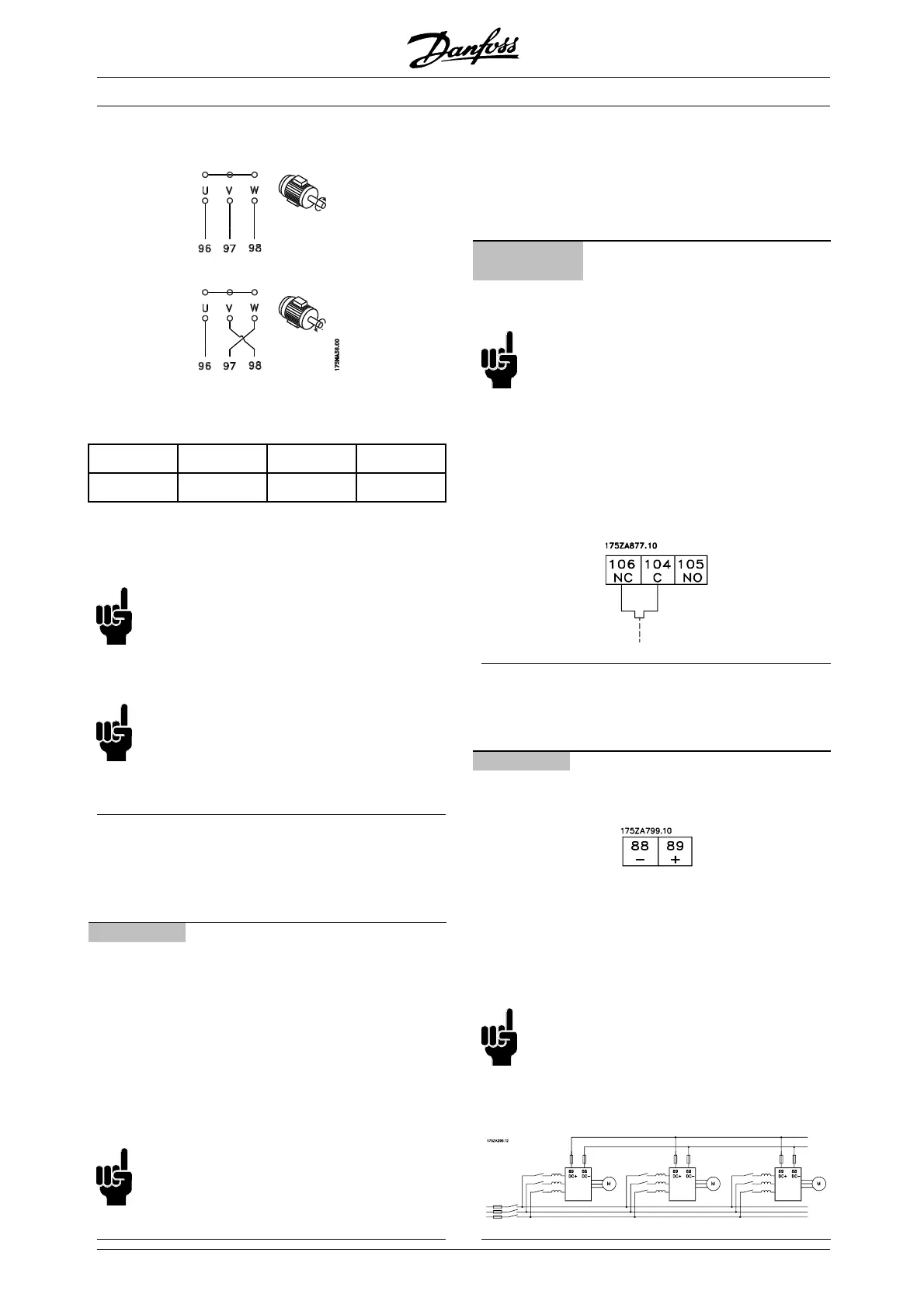

■ Electrical installation - brake resistor

temperature switch

Torque: 0.5-0.6 Nm

Screw size: M3

No. Function

106, 104,

105

Brake resistor temperature switch.

NB!:

This function is only available on VLT 5032-50

52

200-240 V and VLT 5125-5500 380-500 V.

If the temperature of the brake resistor

gets too high and the thermal switch d

rops

out, the frequency converter will stop braking.

The motor will start coasting.

A KLIXON switch must be installed t

hat is ‘normally

closed’. If this function is not used, 106 and 104

must be short-circuited together.

■ Electrical installation - loadsharing

(Only extended with typecode EB, EX, DE, DX).

No. Function

88, 89 Loadsharing

Terminals for loadsharing

The connection cable must be screened and

the max. length from the frequency converter

to the DC bar is 25 metres.

Load sharing enables linking of the DC intermediate

circuits of several frequency converters.

NB!:

Please note that voltages up to 960 V DC

may occur on the terminals.

Load sharing calls for extra equipment. For

further information please consult Loadsharing

Instructions MI.50.NX.XX.

MG.55.A6.02 - VLT is a registered Danfoss trademark

20

Loading...

Loading...