PID for torque controller (open loop)

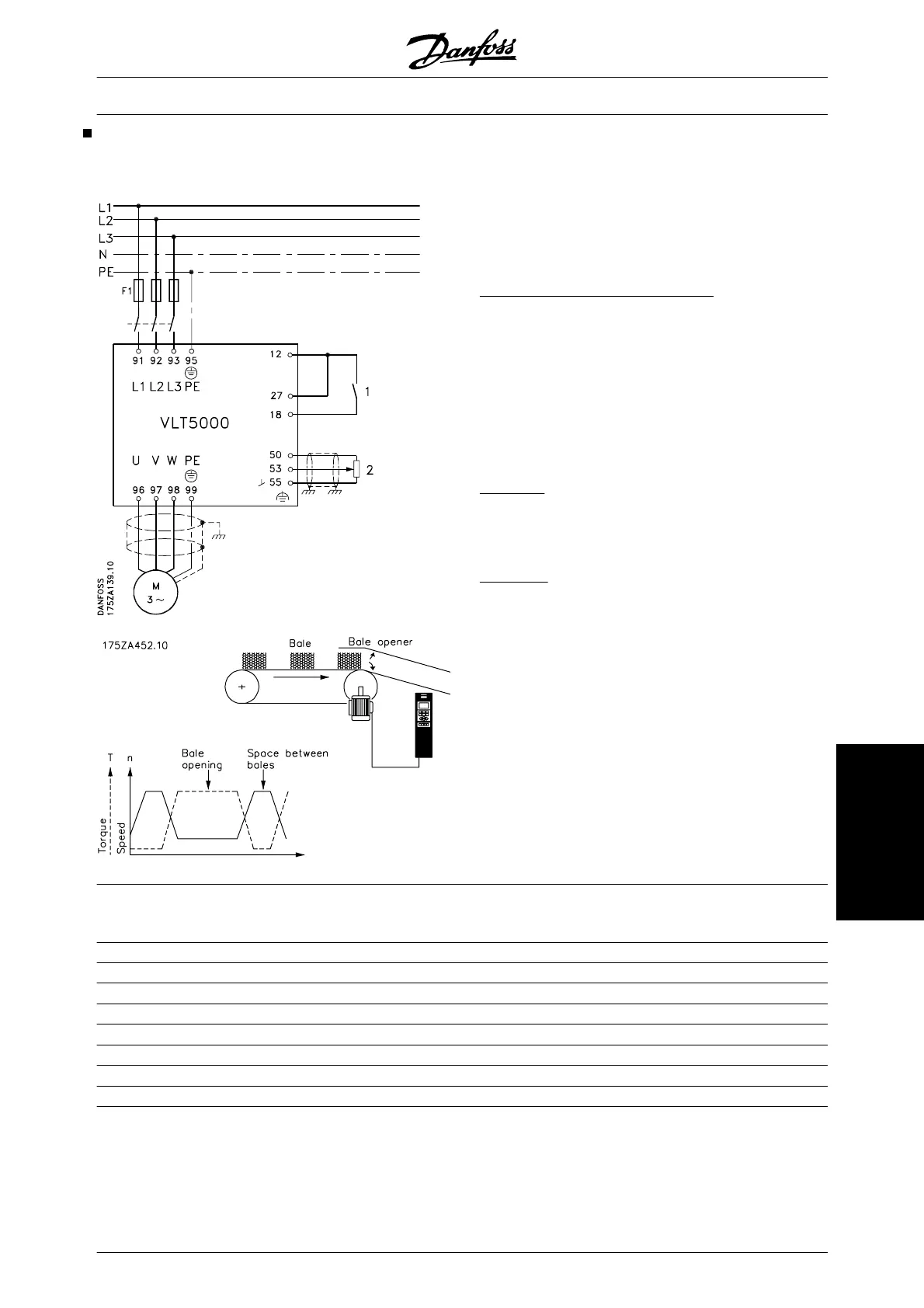

Below is given an example of programming of VLT

5000 torque controller.

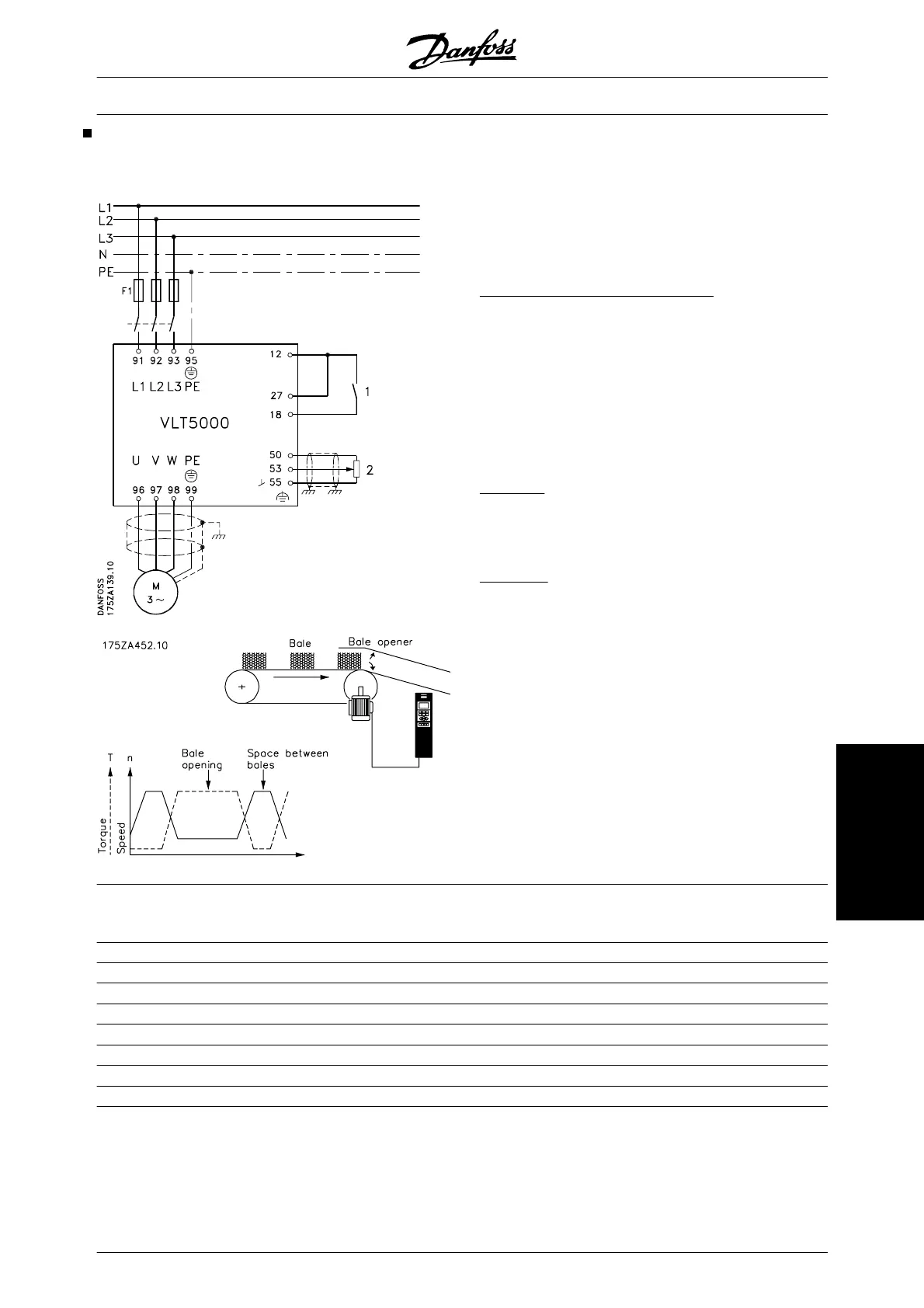

A conveyor belt is used for carrying bales forward to a

shredder at constant force, regardless of the conveyor

belt speed. If there is a space between bales, the con-

veyor belt must move the next bale to the shredder as

quickly as possible.

1. Start/stop.

2. Reference [Nm]

Optimisation of the torque controller

The basic settings have now been made and the fac-

tory setting has been optimised for most processes. It

is rarely necessary to optimize the torque proportional

gain in parameter 433 and the torque integration time

in parameter 434.

In the cases where the factory setting has to be

changed, it is recommended to change this setting by

a maximum factor of +/- 2.

Feedback

The feedback signal is an estimated torque, calculated

by the VLT frequency converter on the basis of the

current values measured.

Reference

The reference is always in Nm.

A minimum and a maximum reference can be set (204

and 205) which limit the sum of all references. The

reference range cannot go beyond the feedback

range.

The following must be programmed in order shown:

Function:

Parameter no. Setting Data value no.

Activation of process controller 100

Torque control, open loop

[4]

Torque proportional gain 433 100% (factory setting)

Torque integration time 434 0.02 sec (factory setting)

Reference 308

Reference (factory setting)

[1]

Terminal 53, min. scale 309 0 volt (factory setting)

Terminal 53, max. scale 310 10 volt (factory setting)

Min. speed 201 0 Hz

Max. speed 202 50 Hz

VLT

®

5000 Design Guide

MG.52.B2.02 - VLT

®

is a registered Danfoss trademark 109

Connection example

Loading...

Loading...