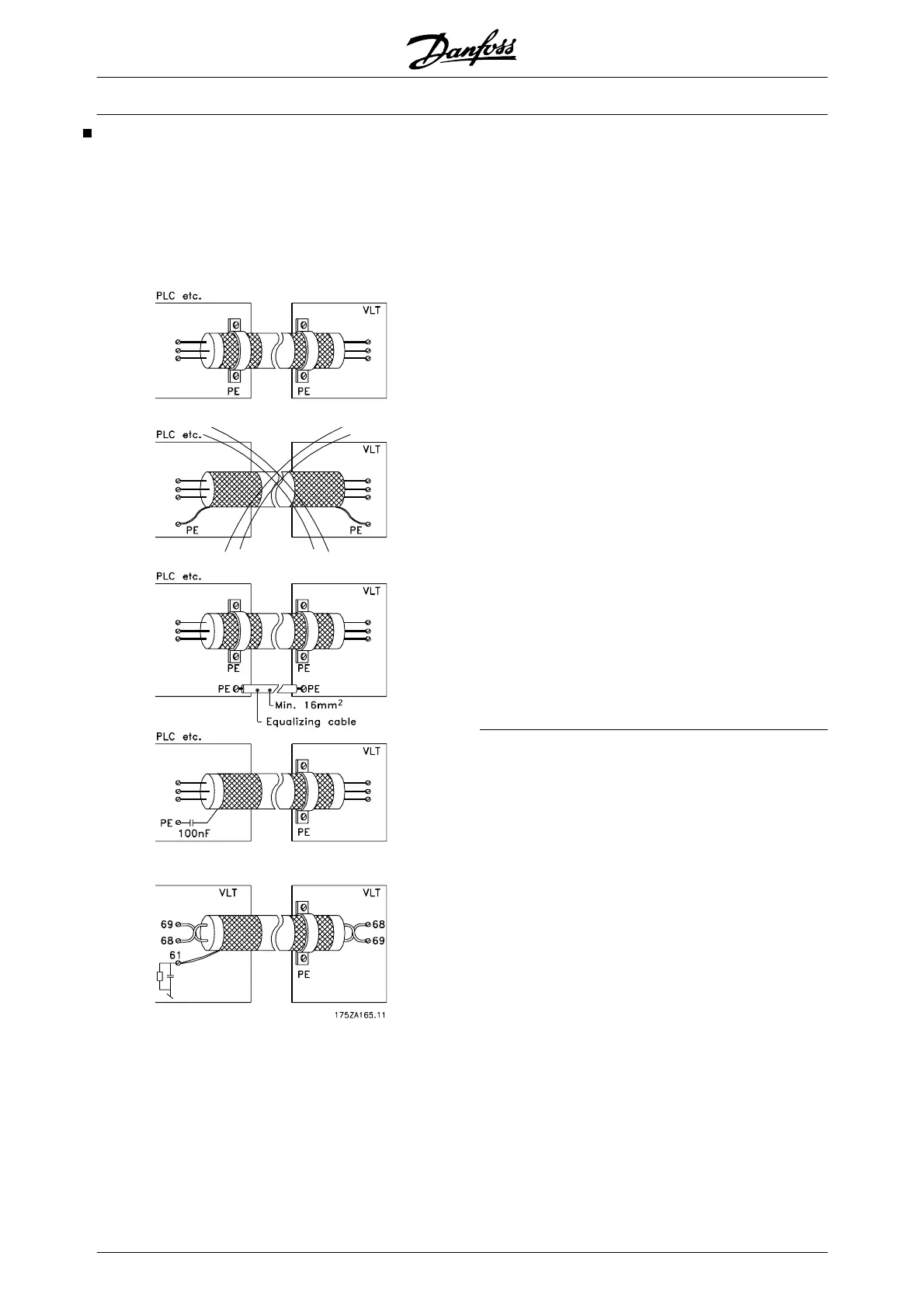

Electrical installation - earthing of control cables

Generally speaking, control cables must be braided

screened/armoured and the screen must be connec-

ted by means of a cable clampat both ends to the metal

cabinet of the unit.

The drawing below indicates how correct earthing is

carried out and what to be done if in doubt.

Correct earthing

Control cables and cables for serial communication

must be fitted with cable clamps at both ends to ensure

the best possible electrical contact

Wrong earthing

Do not use twisted cable ends (pigtails), since these

increase the screen impedance at high frequencies.

Protection with respect to earth potential between

PLC and VLT

If the earth potential between the frequency converter

and the PLC (etc.) is different, electric noise may occur

that will disturb the whole system. This problem can be

solved by fitting an equalising cable, to be placed next

to the control cable. Minimum cable cross-section: 16

mm

2

.

For 50/60 Hz earth loops

If very long control cables are used, 50/60 Hz earth

loops may occur. This problem can be solved by con-

necting one end of the screen to earth via a 100nF

capacitor (keeping leads short).

Cables for serial communication

Low-frequency noise currents between two frequency

converters can be eliminated by connecting one end

of the screen to terminal 61. This terminal is connected

to earth via an internal RC link. It is recommended to

use twisted-pair cables to reduce the differential mode

interference between the conductors.

VLT

®

5000 Design Guide

80 MG.52.B2.02 - VLT

®

is a registered Danfoss trademark

Loading...

Loading...