WARNING

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the

frequency converter properly could result in death or

serious injury.

•

Ensure correct grounding of the equipment by

a certified electrical installer.

9.2 Cables

NOTICE

Cables General

All cabling must comply with national and local

regulations on cable cross-sections and ambient

temperature. Copper (75 °C) conductors are

recommended.

Aluminium Conductors

Terminals can accept aluminium conductors, but the

conductor surface has to be clean and the oxidation must

be removed and sealed by neutral acid-free Vaseline

grease before the conductor is connected.

Furthermore, the terminal screw must be retightened after

2 days due to softness of the aluminium. It is crucial to

keep the connection a gas tight joint, otherwise the

aluminium surface oxidises again.

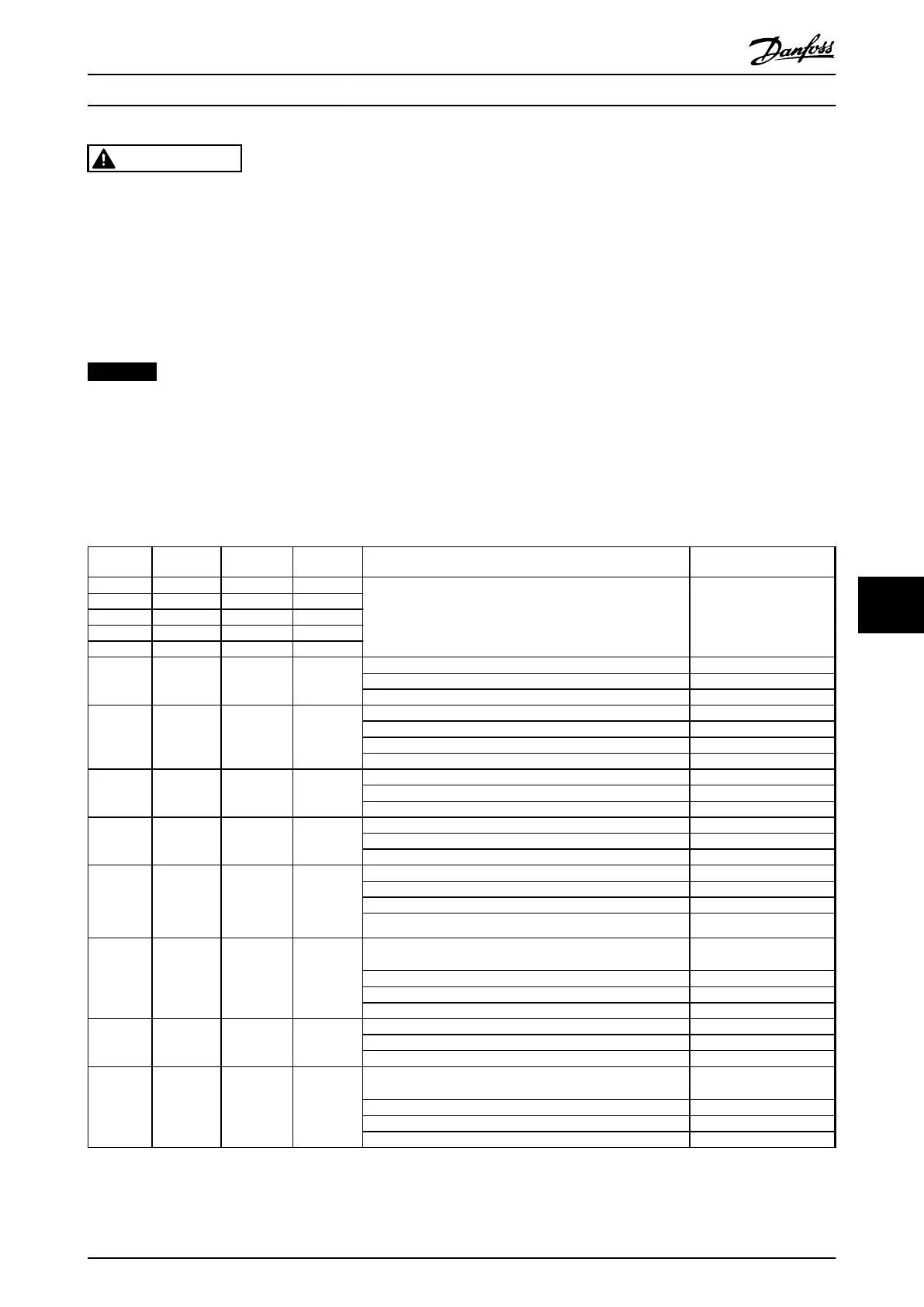

9.2.1 Tightening Torque

Enclosure

Type

200-240 V

[kW]

380-500 V

[kW]

525-690 V

[kW]

Cable for Tightening-up torque

[Nm]

A1 0.25-1.5 0.37-1.5 -

Mains, Brake resistor, load sharing, Motor cables 0.5-0.6

A2 0.25-2.2 0.37-4 -

A3 3-3.7 5.5-7.5 1.1-7.5

A4 0.25-2.2 0.37-4

A5 3-3.7 5.5-7.5 -

B1 5.5-7.5 11-15 -

Mains, Brake resistor, load sharing, Motor cables 1.8

Relay 0.5-0.6

Ground 2-3

B2 11 18.5-22 11-22

Mains, Brake resistor, load sharing cables 4.5

Motor cables 4.5

Relay 0.5-0.6

Ground 2-3

B3 5.5-7.5 11-15 -

Mains, Brake resistor, load sharing, Motor cables 1.8

Relay 0.5-0.6

Ground 2-3

B4 11-15 18.5-30 11-30

Mains, Brake resistor, load sharing, Motor cables 4.5

Relay 0.5-0.6

Ground 2-3

C1 15-22 30-45 -

Mains, Brake resistor, load sharing cables 10

Motor cables 10

Relay 0.5-0.6

Ground 2-3

C2 30-37 55-75 30-75

Mains, motor cables

14 (up to 9 5mm

2

)

24 (over 95 mm

2

)

Load Sharing, brake cables 14

Relay 0.5-0.6

Ground 2-3

C3 18.5-22 30-37 37-45

Mains, Brake resistor, load sharing, Motor cables 10

Relay 0.5-0.6

Ground 2-3

C4 37-45 55-75 -

Mains, motor cables

14 (up to 95 mm

2

)

24 (over 95 mm

2

)

Load Sharing, brake cables 14

Relay 0.5-0.6

Ground 2-3

Table 9.1 Tightening Torque for Cables

Electrical Installation

VLT

®

AutomationDrive FC 301/FC 302 Design Guide, 0.25-75 kW

MG33BF02 - Rev. 2013-12-20 113

9 9

Loading...

Loading...