11.2.2

VLT

®

Encoder Option MCB 102

The encoder module can be used as feedback source for

closed loop Flux control (1-02 Flux Motor Feedback Source)

as well as closed loop speed control (7-00 Speed PID

Feedback Source). Configure encoder option in parameter

group 17-** Feedback Option.

Used for

•

VVC

+

closed loop

•

Flux Vector Speed control

•

Flux Vector Torque control

•

Permanent magnet motor

Supported encoder types:

Incremental encoder: 5 V TTL type, RS-422, max. frequency:

410 kHz

Incremental encoder: 1 Vpp, sine-cosine

Hiperface

®

Encoder: Absolute and Sine-Cosine (Stegmann/

SICK)

EnDat encoder: Absolute and Sine-Cosine (Heidenhain)

Supports version 2.1

SSI encoder: Absolute

NOTICE

Incremental encoders are not recommended for use with

PM motors due to risk of wrong polarity.

NOTICE

It is strongly recommended to always supply the

encoder through the MCB 102. It shall be avoided to use

external power supply for the encoder.

Encoder monitor:

The 4 encoder channels (A, B, Z and D) are monitored,

open and short circuit can be detected. There is a green

LED for each channel which lights up when the channel is

OK.

NOTICE

The LEDs are only visible when removing the LCP.

Reaction in case of an encoder error can be selected in

17-61 Feedback Signal Monitoring: [0] Disabled, [1]

Warning or [2] Trip.

When the encoder option kit is ordered separately, the

kit includes

•

Encoder Option MCB 102

•

Enlarged LCP fixture and enlarged terminal cover

The encoder option does not support FC 302 frequency

converters manufactured before week 50/2004.

Min. software version: 2.03 (15-43 Software Version)

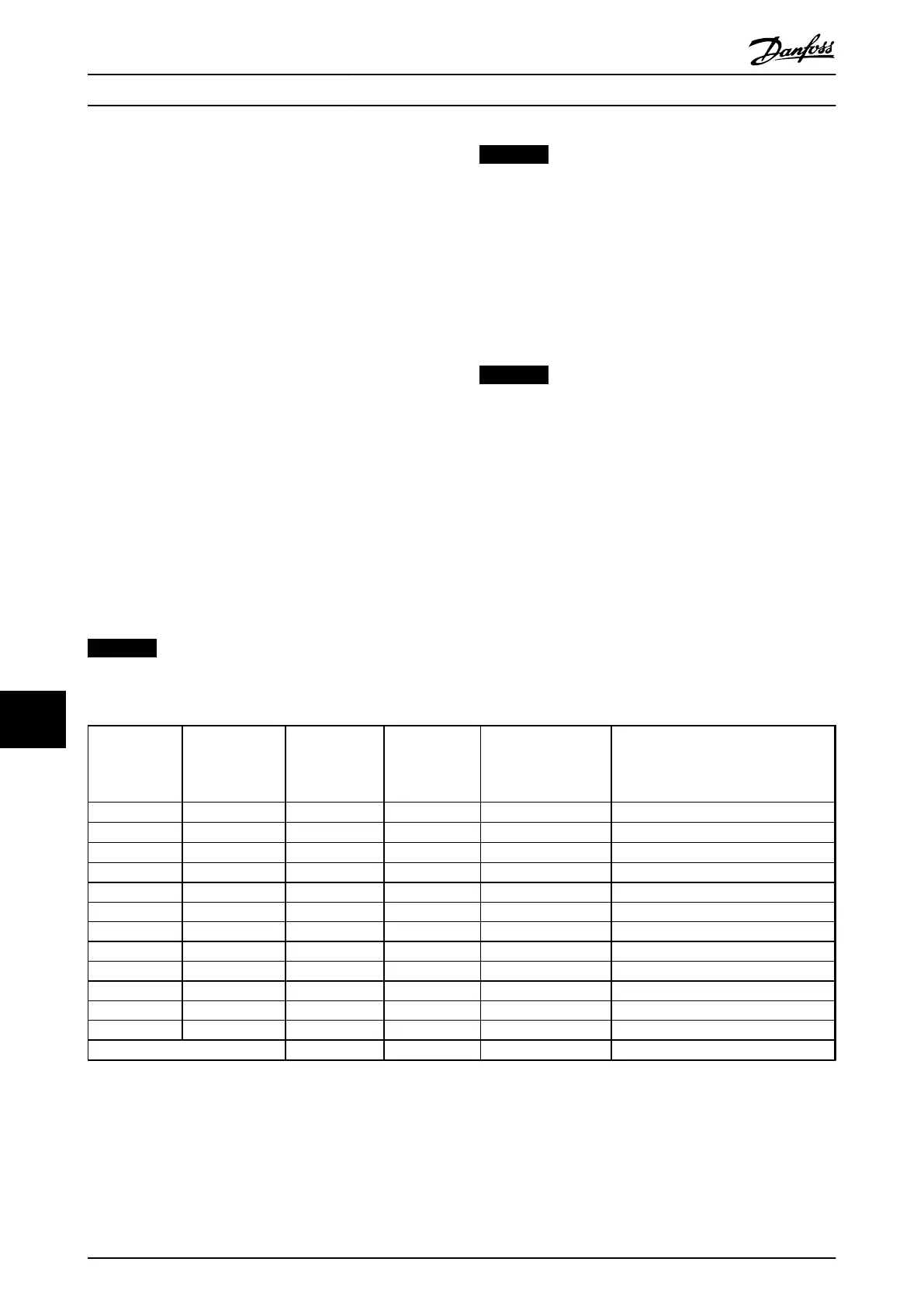

Connector

Designation

X31

Incremental

Encoder (refer to

Illustration 11.3)

SinCos Encoder

Hiperface

®

(refer to

Illustration 11.4)

EnDat Encoder SSI Encoder Description

1 NC 24 V* 24 V Output (21-25 V, I

max

:125 mA)

2 NC 8 VCC 8V Output (7-12V, I

max

: 200mA)

3 5 VCC 5 VCC 5 V* 5 V Output (5 V ± 5%, I

max

: 200 mA)

4 GND GND GND GND

5 A input +COS +COS A input

6 A inv input REFCOS REFCOS A inv input

7 B input +SIN +SIN B input

8 B inv input REFSIN REFSIN B inv input

9 Z input +Data RS-485 Clock out Clock out Z input OR +Data RS-485

10 Z inv input -Data RS-485 Clock out inv. Clock out inv. Z input OR -Data RS-485

11 NC NC Data in Data in Future use

12 NC NC Data in inv. Data in inv. Future use

Max. 5 V on X31.5-12

Table 11.1 Encoder Connections

* Supply for encoder: see data on encoder

Options and Accessories

VLT

®

AutomationDrive FC 301/FC 302 Design Guide, 0.25-75 kW

154 MG33BF02 - Rev. 2013-12-20

1111

Loading...

Loading...