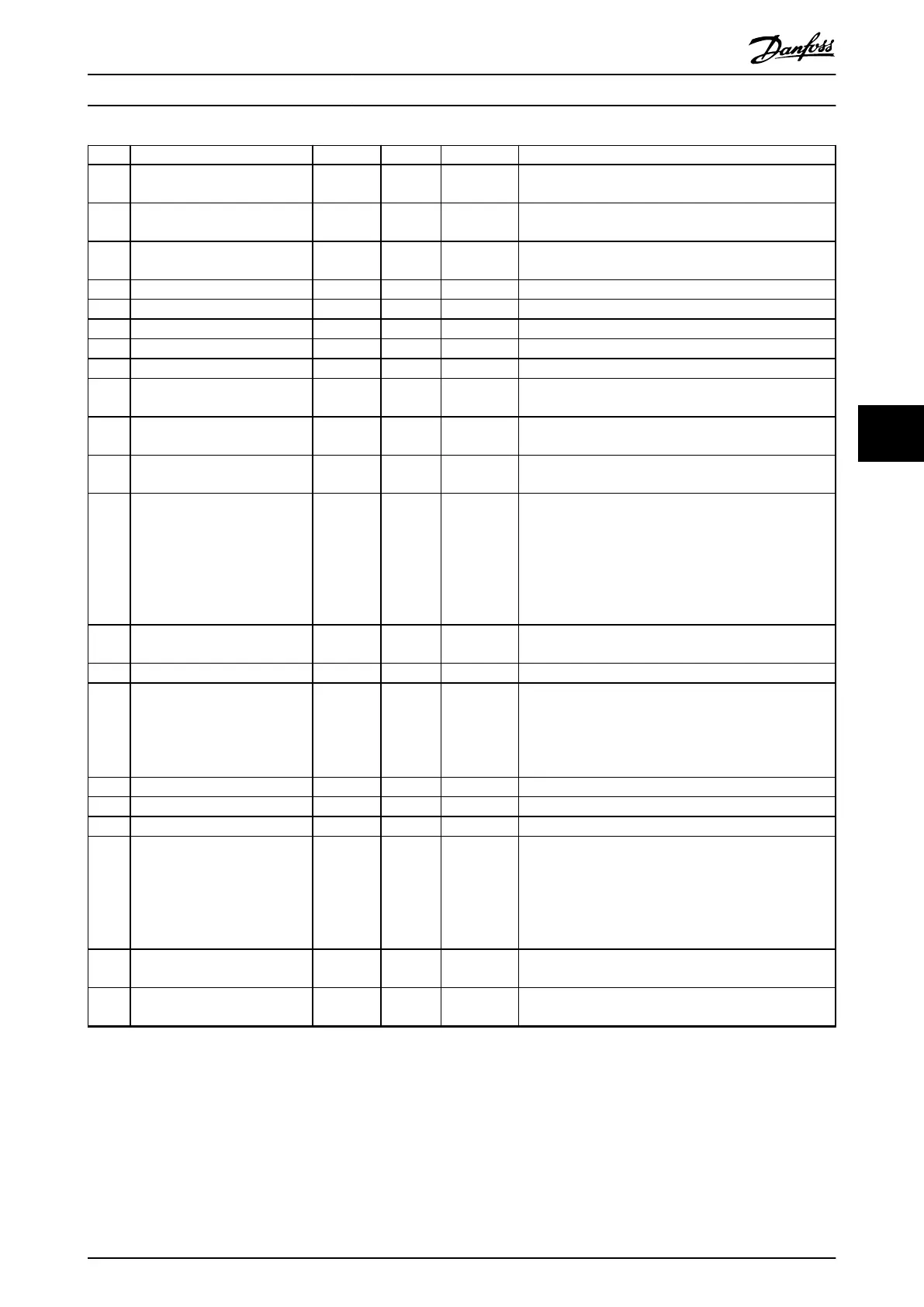

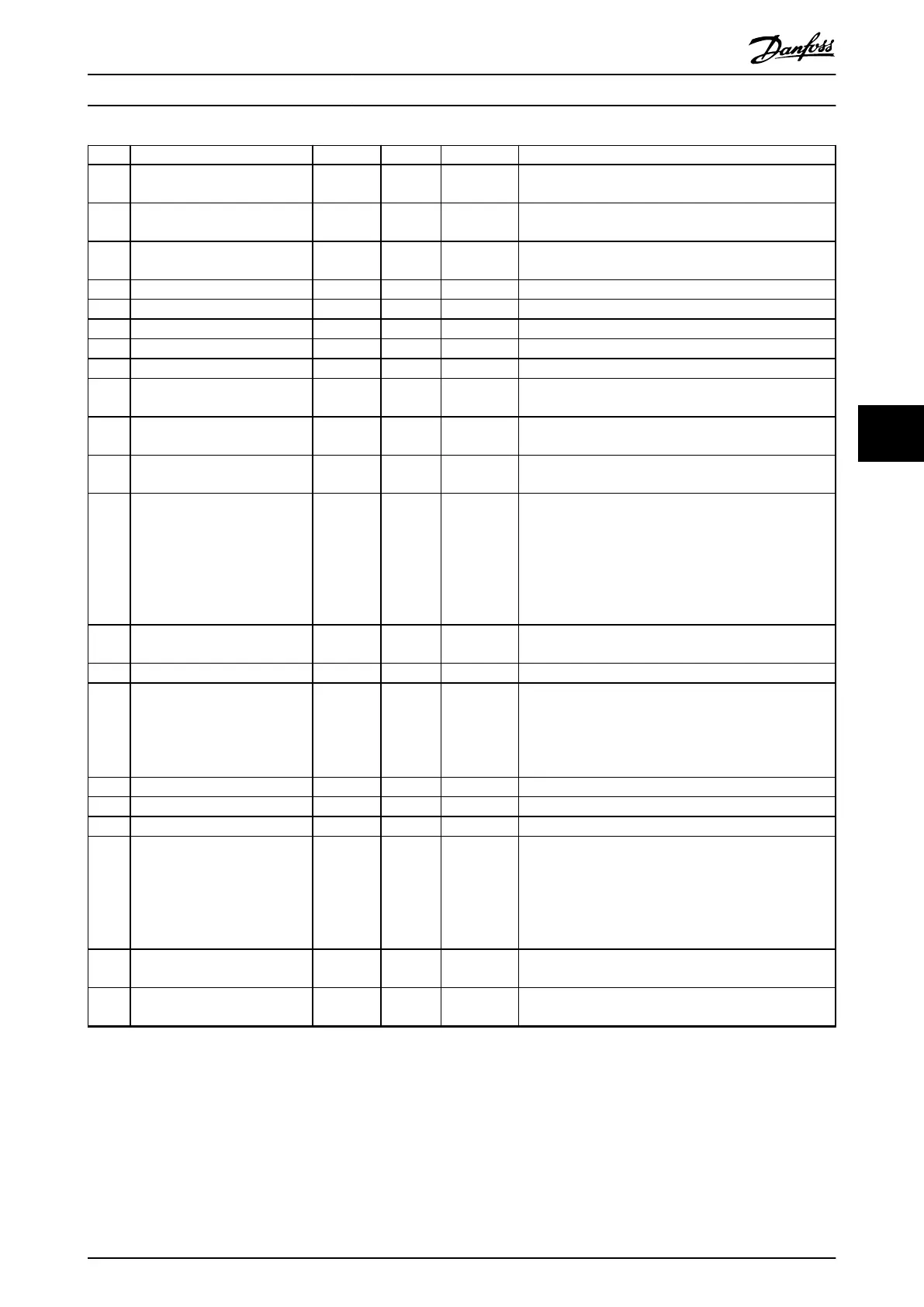

No. Description Warning Alarm Trip lock Cause

53 AMA big motor

– X –

The power size of the motor is too large for the AMA to

operate.

54 AMA small motor

– X –

The power size of the motor is too small for the AMA to

operate.

55 AMA parameter range – X –

The parameter values of the motor are outside of the

acceptable range. AMA does not run.

56 AMA interrupt – X – The AMA is interrupted.

57 AMA timeout – X – –

58 AMA internal – X – Contact Danfoss.

59 Current limit X X – Frequency converter overload.

61 Encoder loss X X – –

63 Mechanical brake low – X –

Actual motor current has not exceeded release brake-

current within start delay-time window.

65 Control card temp

X X X

The cut-out temperature of the control card has

exceeded the upper limit.

67 Option change

– X –

A new option is detected or a mounted option is

removed.

68 Safe Stop

X X –

STO is activated. If STO is in manual restart mode

(default), to resume normal operation, apply 24 V DC to

terminals 37 and 38, and initiate a reset signal (via

eldbus, digital I/O, or [Reset]/[O Reset] key). If STO is in

automatic restart mode, applying 24 V DC to terminals 37

and 38 automatically resumes the frequency converter to

normal operation.

69 Power card temp

X X X

The cut-out temperature of the power card has exceeded

the upper limit.

80 Drive initialised to default value – X – All parameter settings are initialized to default settings.

87 Auto DC braking X – –

Occurs in IT mains when the frequency converter coasts,

and the DC voltage is higher than 830 V for 400 V units,

and 425 V for 200 V units. The motor consumes energy

on the DC link. This function can be enabled/disabled in

parameter 0-07 Auto DC Braking.

88 Option detection – X X The option is removed successfully.

95 Broken belt X X – –

120 Position control fault – X – –

188 STO internal fault

– X –

24 V DC supply is connected to only 1 of the 2 STO

terminals (37 and 38), or a failure in STO channels is

detected. Ensure that both terminals are connected to

24 V DC supply, and that the discrepancy between the

signals at the 2 terminals is less than 12 ms. If the fault

still occurs, contact the local Danfoss supplier.

nw

run

Not while running – – –

Parameter can only be changed when the motor is

stopped.

Err. A wrong password was entered – – –

Occurs when using a wrong password for changing a

password-protected parameter.

Table 6.2 Warnings and Alarms Code List

1) Mains distortions may cause these faults. Installing a Danfoss line lter may rectify this problem.

For diagnosis, read out the alarm words, warning words, and extended status words.

Troubleshooting Programming Guide

MG07C102 Danfoss A/S © 12/2015 All rights reserved. 135

6

6

Loading...

Loading...