Chapter 12 Descriptions of Parameter SettingsC2000 Plus

12.1-08-3

00-20

Master Frequency Command Source (AUTO) / Source Selection of The

PID Target

Default: 0

Settings 0: Digital keypad

1: RS-485 communication input

2: External analog input (Refer to Pr.03-00–03-02)

3: External UP / DOWN terminal (multi-function input terminals)

4: Pulse input without direction command (refer to Pr.10-16 without

considering direction), use with PG card

5: Pulse input with direction command (refer to Pr.10-16), use with PG card

6: CANopen communication card

8: Communication card (does not include CANopen card)

03-00

AVI Analog Input Selection

Default: 1

03-01

ACI Analog Input Selection

Default: 0

03-02

AUI Analog Input Selection

Default: 0

Settings 0: No function

1: Frequency command (speed limit under torque control mode)

4: PID target value

5: PID feedback signal

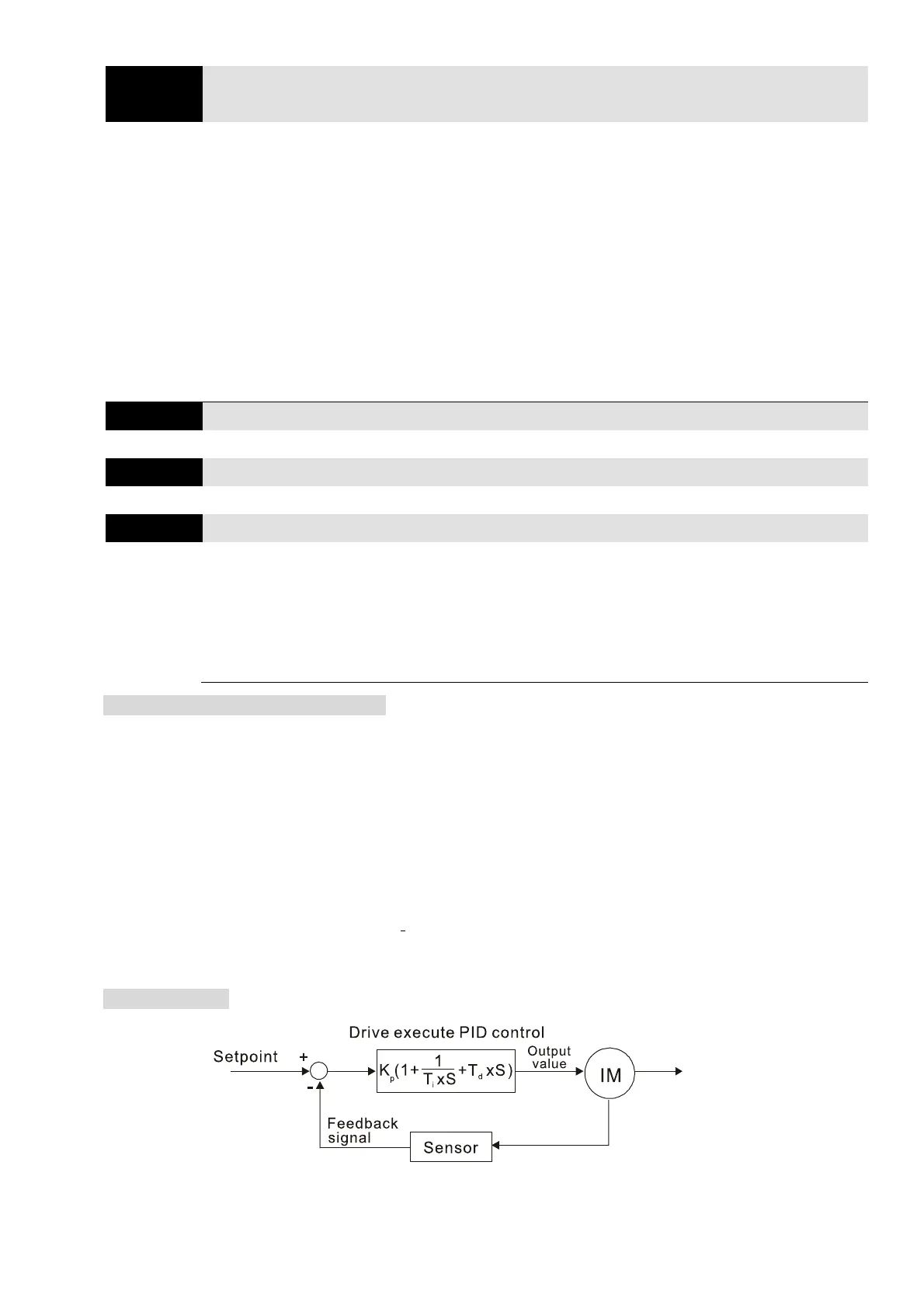

Common applications for PID control:

Flow control: Use a flow sensor to feedback the flow data and perform accurate flow control.

Pressure control: Use a pressure sensor to feedback the pressure data and perform precise

pressure control.

Air volume control: Use an air volume sensor to feedback the air volume data to achieve

excellent air volume regulation.

Temperature control: Use a thermocouple or thermistor to feedback temperature data for

comfortable temperature control.

Speed control: Use a speed sensor to feedback motor shaft speed or input another machine

speed as a target value for synchronous control.

PID control loop:

K

P

Proportional Gain (P), T

i

Integral Time (I), T

d

Differential Time (D), S Calculation

Loading...

Loading...