FORMATTING MESSAGES

77091 Issue 2 November 2003 79

example, is always day 365, whether it is a leap year or not. To follow this system,

use the UVW code.

After the 29th of February in leap years, the KLM code will print a value one day

ahead of the value printed by UVW.

A full list of the available formatting letters is given below.

For example:

In this example, the brackets frame the letters AB and CD separated by a colon.

This code prints the current time in hours and minutes, using the colon to separate

the two numbers - 12:15, for example. AB represents hours (in the twenty-four

hour clock 00 to 23) and CD represents minutes (00 to 59).

Here the punctuation mark / has been used to separate the three sets of code

letters EF, GH and IJ. It prints the current date in day, month and year order - 25/

01/01, for example.

When printed, day of the year (either code) always pads out values under 100 with

zeros - for instance 001 or 023. Numerical day of week (P) can have the value 1 to

7, and alphabetical day of week (X) the corresponding letter A to G.

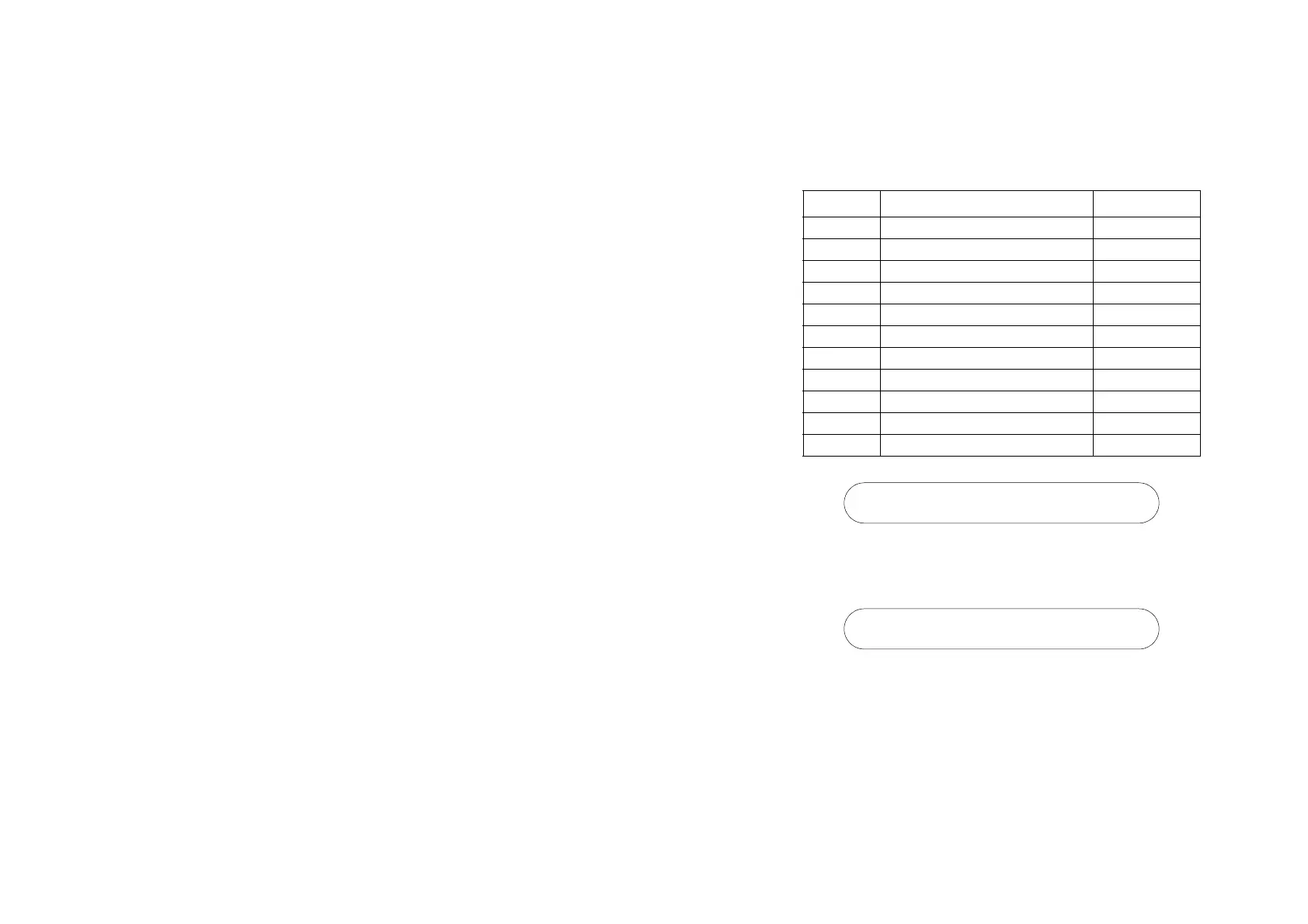

Code Meaning Example

AB Hours 23

CD Minutes 59

EF Day 31

GH Month 12

IJ Year 01

KLM Day of the year 366

NO Week number 52

P Day of week (number) 7

RST Month in words DEC

UVW Julian day of the year 365

X Day of week (letter) G

[AB:CD]

[EF/GH/IJ]

Loading...

Loading...