INSTALLATION

32 77091 Issue 2 November 2003

Avoid locations where operators or machinery moving close to the printer are

likely to trigger the photocell. Do not place the printer opposite a large reflective

area as this may also trigger the photocell. When printing on both sides of

product, never place the two printers exactly opposite - the photocells will trigger

each other.

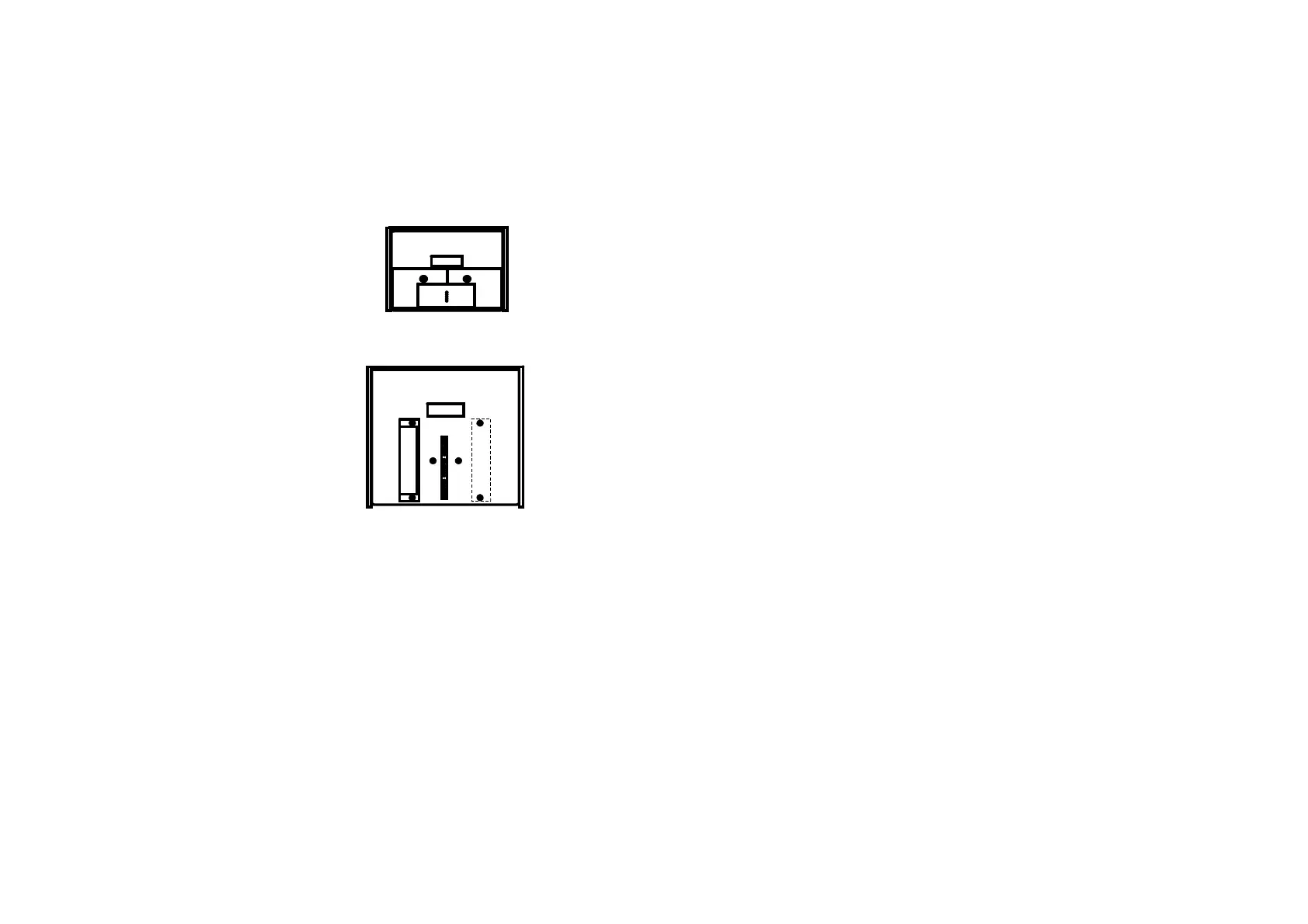

Buffer plate

Each printer incorporates a buffer plate to

afford some protection to the nozzle plate, to

provide a degree of print-head-to-product

spacing for correct character generation and

to help prevent smearing before the ink

dries. In the C16, this is built into the nozzle

plate itself.

In all other models, the buffer plate is

separate to the nozzle plate and is bolted in

place. The position of the buffer plate may

need to be changed to correspond with the

direction of product movement on the

conveyor - make sure that the product

reaches the buffer plate before it reaches the

nozzle plate. This involves removing the

print head cover, which is explained in the

MAINTENANCE chapter of this manual.

Mounting the printer

The exploded diagram (below) shows the arrangement of components used in the

mounting of a printer with a one litre base. Items A and B are not required when

installing a three litre base as they are built into the base unit.

Combined Buffer and

Nozzle Plate

Separate Buffer Plate

- Position as Required

Loading...

Loading...