63

TESTS & ALIGNMENTS

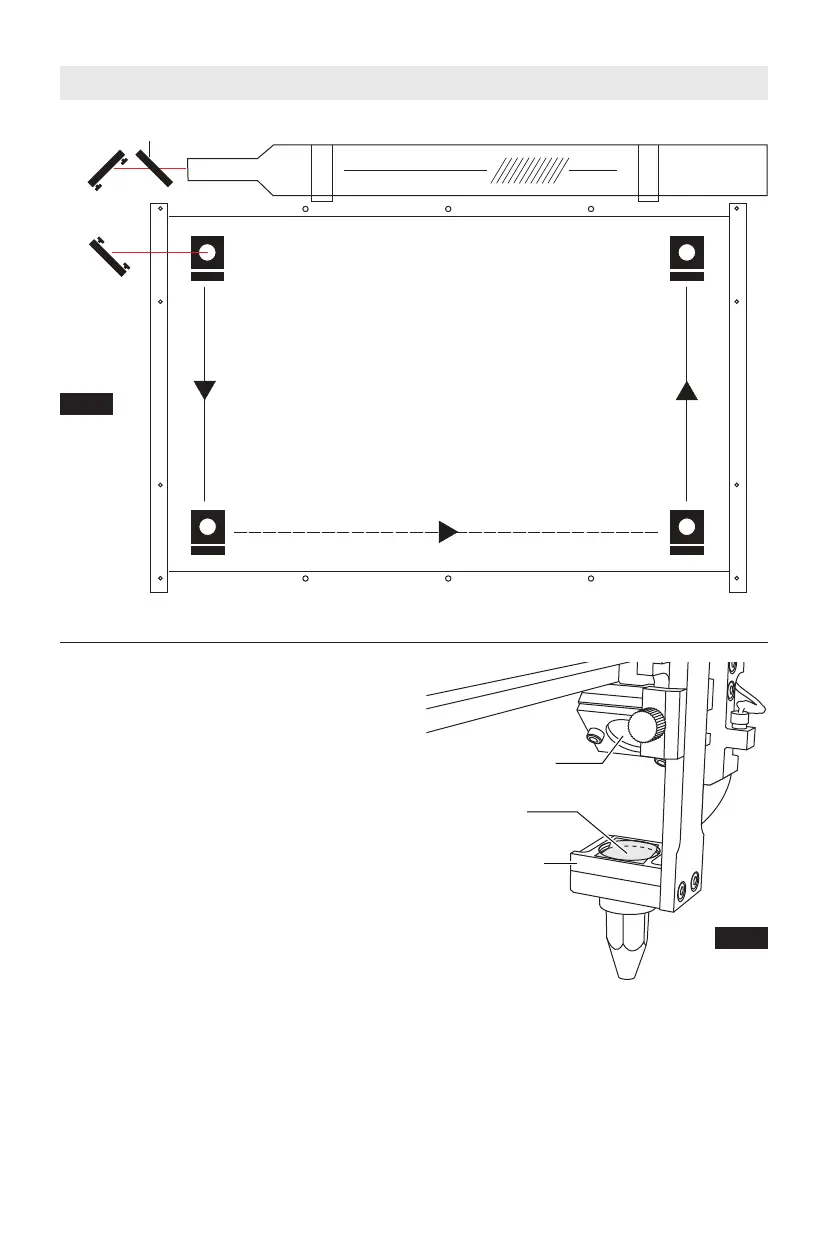

4 Corner Mirror Alignment Test

Before running the first job, check to

make sure that the mirrors are properly

aligned. This test should also be

performed as a troubleshooting measure

for power loss, clipping, or incomplete

cutting. For this alignment test the laser

must be “test fired” once in each corner

of the machine. This is done to make sure

the laser beam is following the correct

path to the mirrors, to the focus head,

and ultimately through the lens to the

material. Figure 32, Mirror Alignment

Layout.

Note: Laser lid must be closed for each

test fire.

Materials needed:

• Thermal paper (supplied).

• 2.5mm hex wrench (supplied).

1. Open the lid.

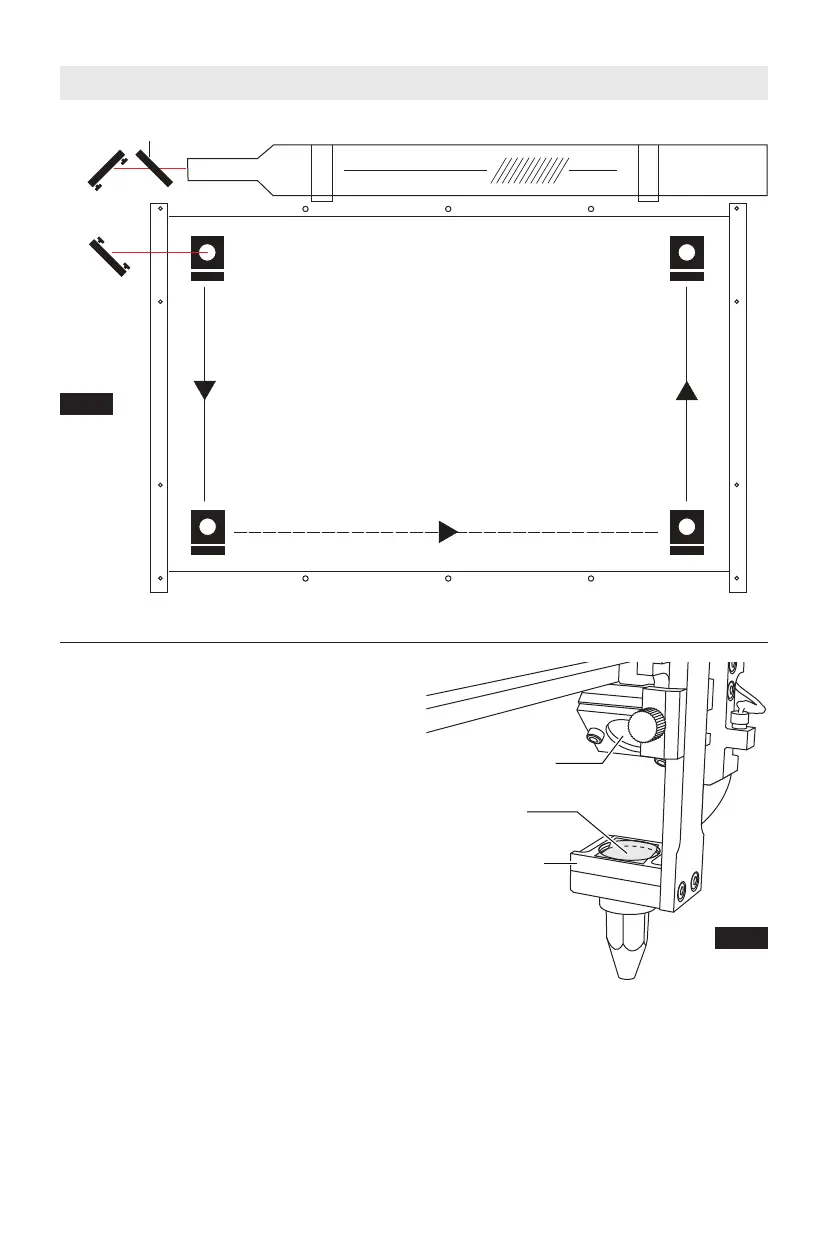

2. Place the thermal paper: Take a small

piece of thermal paper approximately

the same size as the face of the lens

and place it over the focus lens under

Mirror #3. See figure 33.

3. Press the paper down with a finger so

that a circle appears that

demonstrates the outer rim of the

lens. Sometimes pencil lead or crayon

will help to show the edges of the lens

and mirrors.

Test Fire

Test Fire

Test Fire

Test Fire

A

BC

D

Mirror 1

M

irror 2

Laser Head

Mirror 3

Axis A-B

Axis B-C

A

xis C-D

Beam Combiner

L

ens

Focus Lens

Mirror 3

Fig. 33

Fig. 32

Mirror

Alignment

Layout

Thermal

Paper

Loading...

Loading...