AGL_Sol_EV3_E_Rev_02 7

3.3 Mounting

The drive should be located as close to the compressor as possible, preferably within 1 metre of the

compressor. To avoid electromagnetic interference please ensure that the motor cables do not cross

or attach to any other connecting cables.

There should be at least a natural air stream inside the cabinet and around the drive to keep the

temperature below 60 °C.

There are holes in the drive mounting flange for mounting purposes. These holes will accommodate

M6 sized screws.

The panel on which the EV3 drive is mounted must be able to support its weight, ie, 17 kg.

The drive should be positioned in such a way that the input and output terminals are on the bottom

side. After connecting the input and output cables, one must not forget to place back the protection

cover for the terminals.

Caution: Respect the maximum screw torques to avoid any damage to the frame:

▪ M5 screws: 3.9 Nm

▪ M6 screws: 6.7 Nm

To achieve better cooling it is recommended to mount the drive in the lower or middle part of the

cabinet. Ensure that the drive is mounted in such a way that good natural convection is possible.

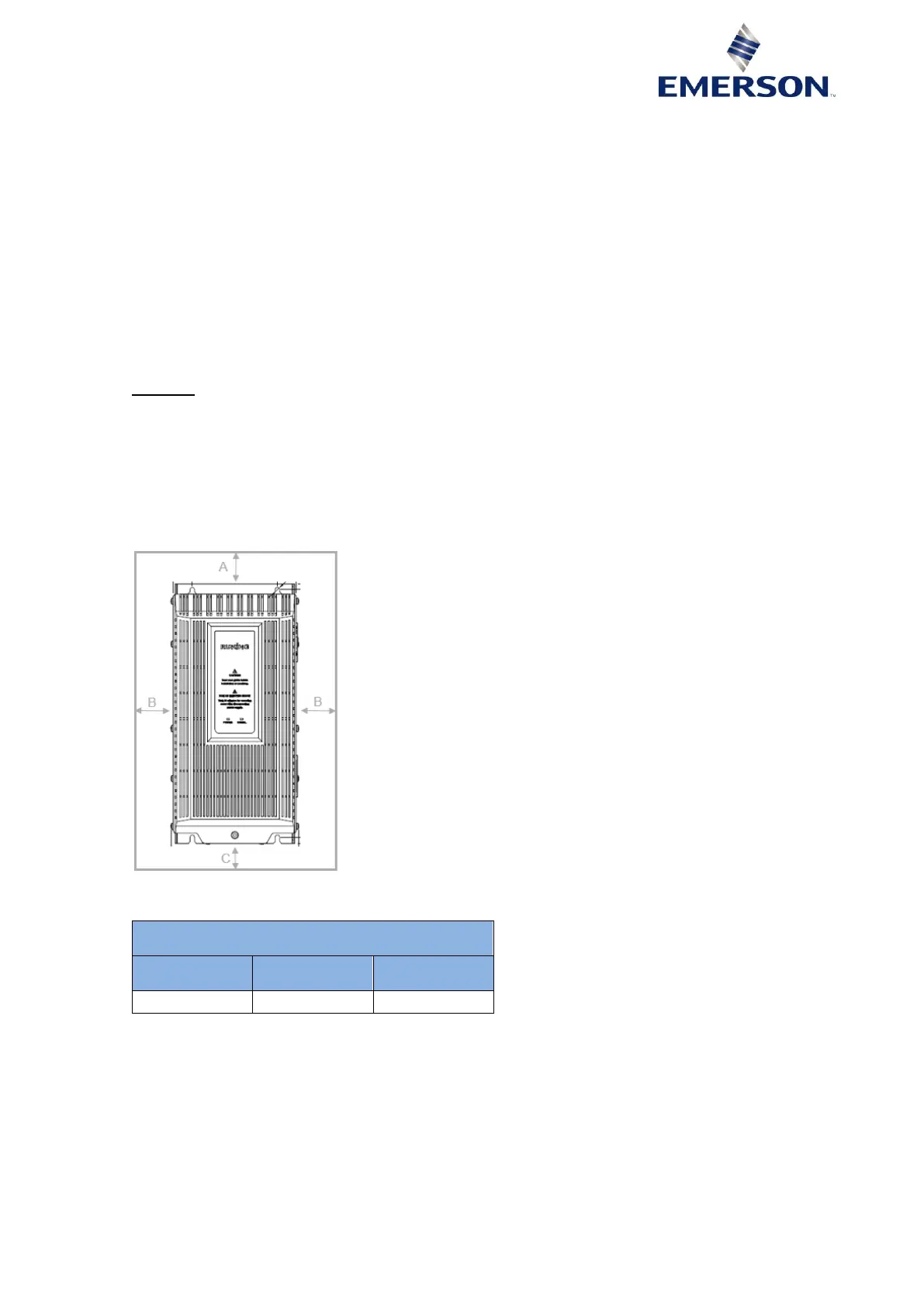

Figure 3 and Table 7 below show the minimum clearance spaces to other components and devices

near the drive. In addition to those requirements, a decent height between the case and other

components and devices is needed.

Figure 3: Minimum mounting clearances

Recommended minimum clearance space

on the top, bottom, left and right sides

Table 7: Clearance to other components and devices

NOTE: The clearance spaces provided in Table 7 should be used only for space to other

components/devices and not as a reference for the cabinet dimensions in which the EV3 drive

will be placed.

NOTE: For more information about drive dimensions and mounting please refer to

Appendix 1.

Loading...

Loading...