6

1. Unscrew the 10 bolts holding the coverplate to the reservoir

and lift the pump unit out of the reservoir. Be careful not to

damage the filter screen.

2. Pour all oil out of the reservoir.

3. Thoroughly clean the reservoir with a suitable cleaning agent.

4. Remove the pick-up filter for cleaning. Clean the screen with

solvent and a soft brush. Reinstall the filter.

5. Reassemble the pump and reservoir, installing a new

reservoir gasket.

6. Fill the reservoir with clean Enerpac hydraulic oil. The

reservoir is full when oil level is at the top mark (full mark) of

the sight gauge.

6.3 Changing the (optional) Filter Element

A return line filter may be ordered as an accessory to the pump.

The filter element should be replaced every 250 hours, or more

frequently in dirty environments. The filter manifold is equipped

with a 25 psi (1,7 bar) bypass to prevent over pressure rupture if

filter plugging occurs. Filter element replacement part number is

PF-25.

7.0 TROUBLESHOOTING (see Trouble-shooting

Guide)

Only qualified hydraulic technicians should service the pump or

system components. A system failure may or may not be the result

of a pump malfunction. To determine the cause of the problem, the

complete system must be included in any diagnostic procedure.

The following information is intended to be used only as an aid in

determining if a problem exists. For repair service, contact your

local Authorized Enerpac Service Center.

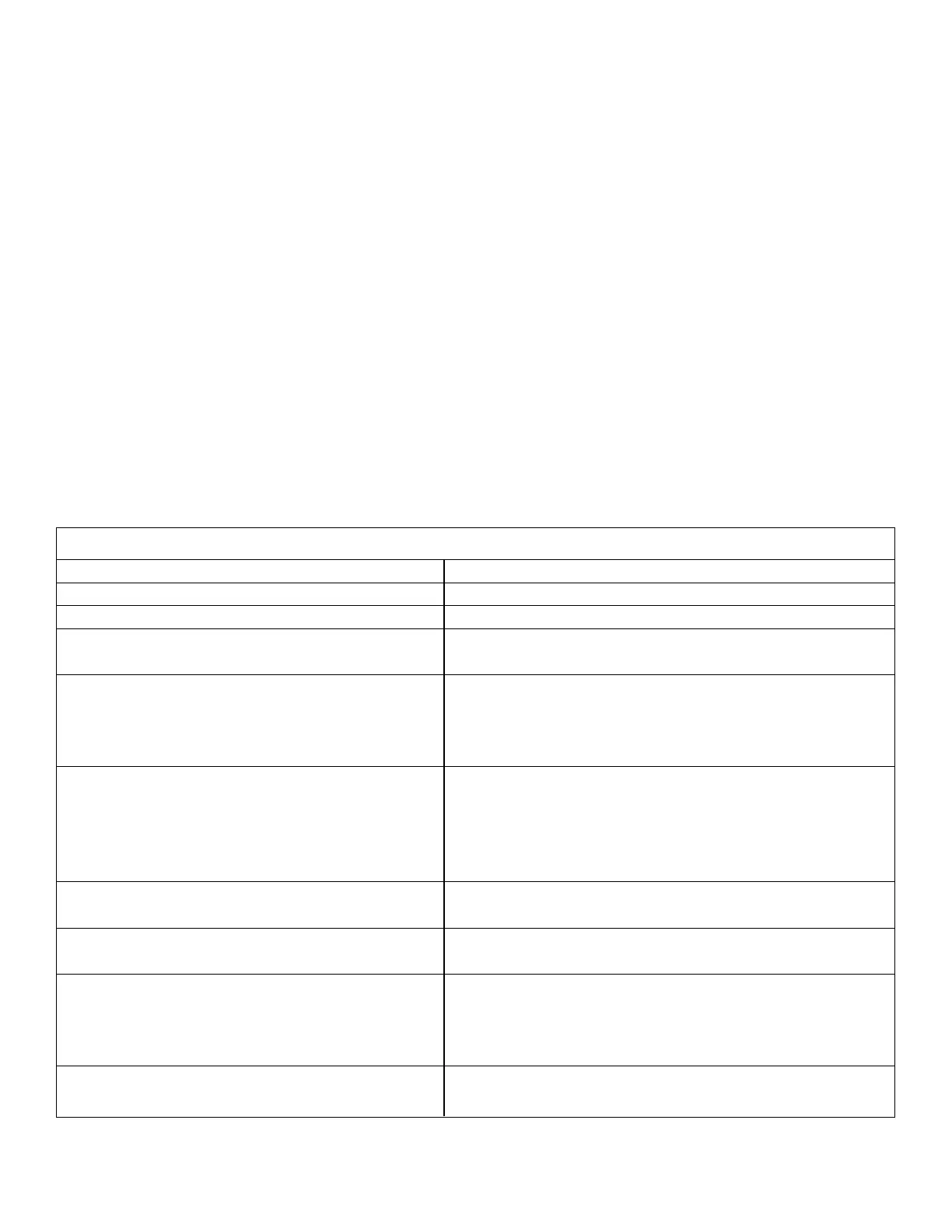

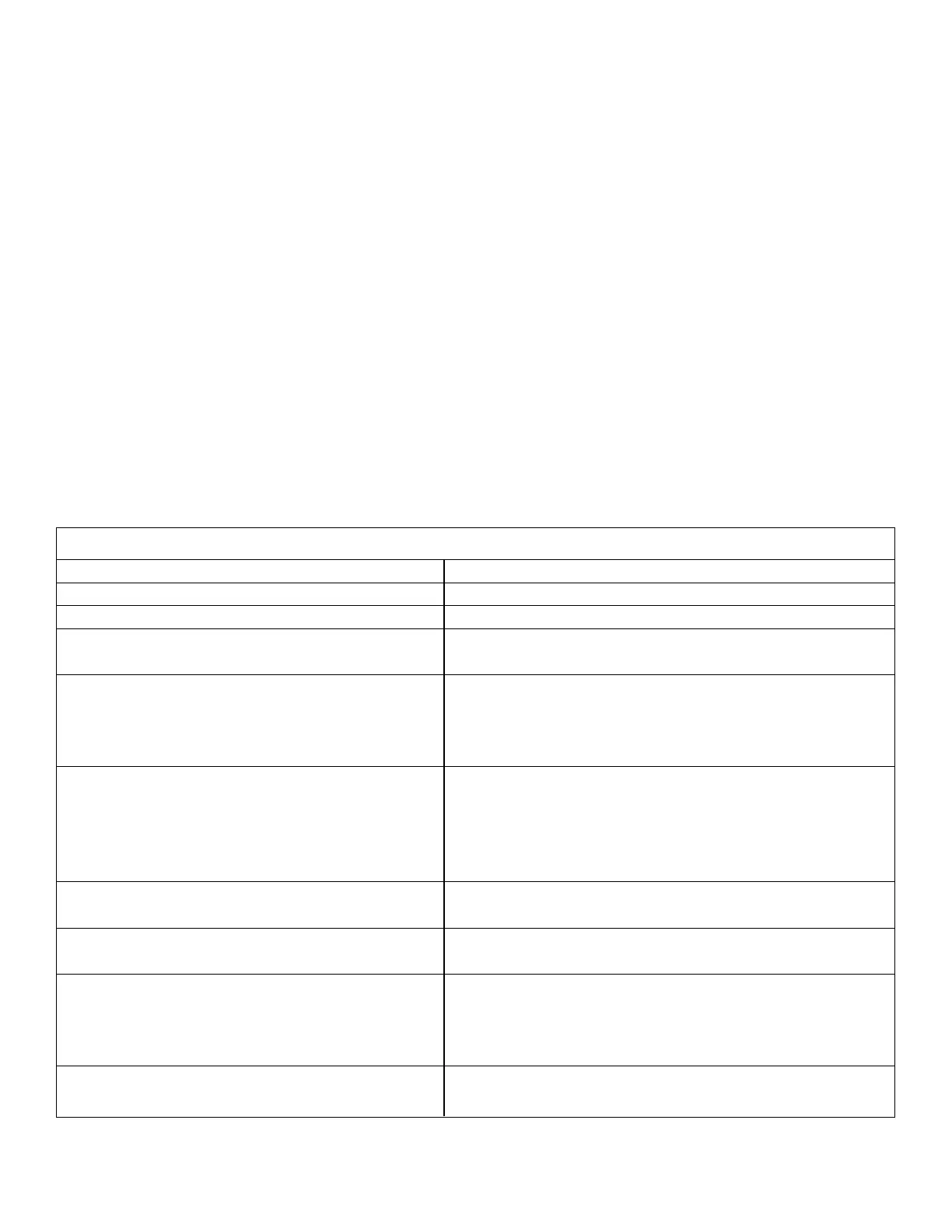

Trouble-shooting Guide

Problem Possible Cause

Pump will not start No power or wrong voltage

Motor stalls under load Low voltage

Electric valve will not operate No power or wrong voltage

Valve out of adjustment

Pump fails to build pressure External system leak

Internal leak in pump

Internal leak in valve

Internal leak in system component

Pump builds less than full pressure Relief valve set too low

External system leak

Internal leak in pump

Internal leak in valve

Internal leak in system component

Pump builds full pressure, but load does not move Load greater than cylinder capacity at full pressure

Flow to cylinder blocked

Cylinder drifts back on its own External system leak

Internal leak in a system component

Single-acting cylinder will not return Valve malfunction

Cylinder return spring broken

Return flow restricted or blocked

No load on a "load return" cylinder

Double-acting cylinder will not return Valve malfunction

Return flow restricted or blocked

Loading...

Loading...