Instruction Manual

D103175X012

GX Valve and Actuator

July 2017

7

Actuator Disassembly (For Air‐to‐Close Constructions ‐ see figure 20 or 21)

1. Remove the stem connector nut half (key 23), stem connector bolt half (key 24), and travel indicator (key 26).

WARNING

To avoid personal injury or property damage due to actuator springs (key 12) being under compression, remove the long

cap screws (key 16) last.

The upper actuator casing may remain fixed to the diaphragm and lower casing during disassembly, even if the casing cap

screws have been loosened. If this happens, the actuator springs are still under compression. The upper casing could

suddenly come loose and jump, due to the compressed energy of the springs. If the upper casing is stuck to the diaphragm

and lower casing when you begin loosening the casing cap screws, pry the casings apart with a prying tool. Always ensure

that the springs are dispersing energy and the upper casing is moving against the long bolts during disassembly.

2. Remove the short actuator casing cap screws and hex nuts (keys 17 and 18) first. Once these have been removed

from the actuator assembly, carefully remove the long actuator cap screws and hex nuts (keys 16 and 18),

alternating between them to gradually release the spring energy (compression).

3. Remove the upper diaphragm casing (key 9).

4. Lift off the actuator stem/diaphragm assembly (includes keys 22, 11, 10, 14, 13, 109, and 15) and remove the cap

screw (key 14), actuator spacer (key 13), actuator rod (key 22), and washer (key 15).

5. Remove the actuator springs (key 12 and/or 82).

6. Replace the diaphragm (key 10), diaphragm O-ring (key 109), actuator rod bushing (key 19), and actuator rod seal

(key 20), as needed.

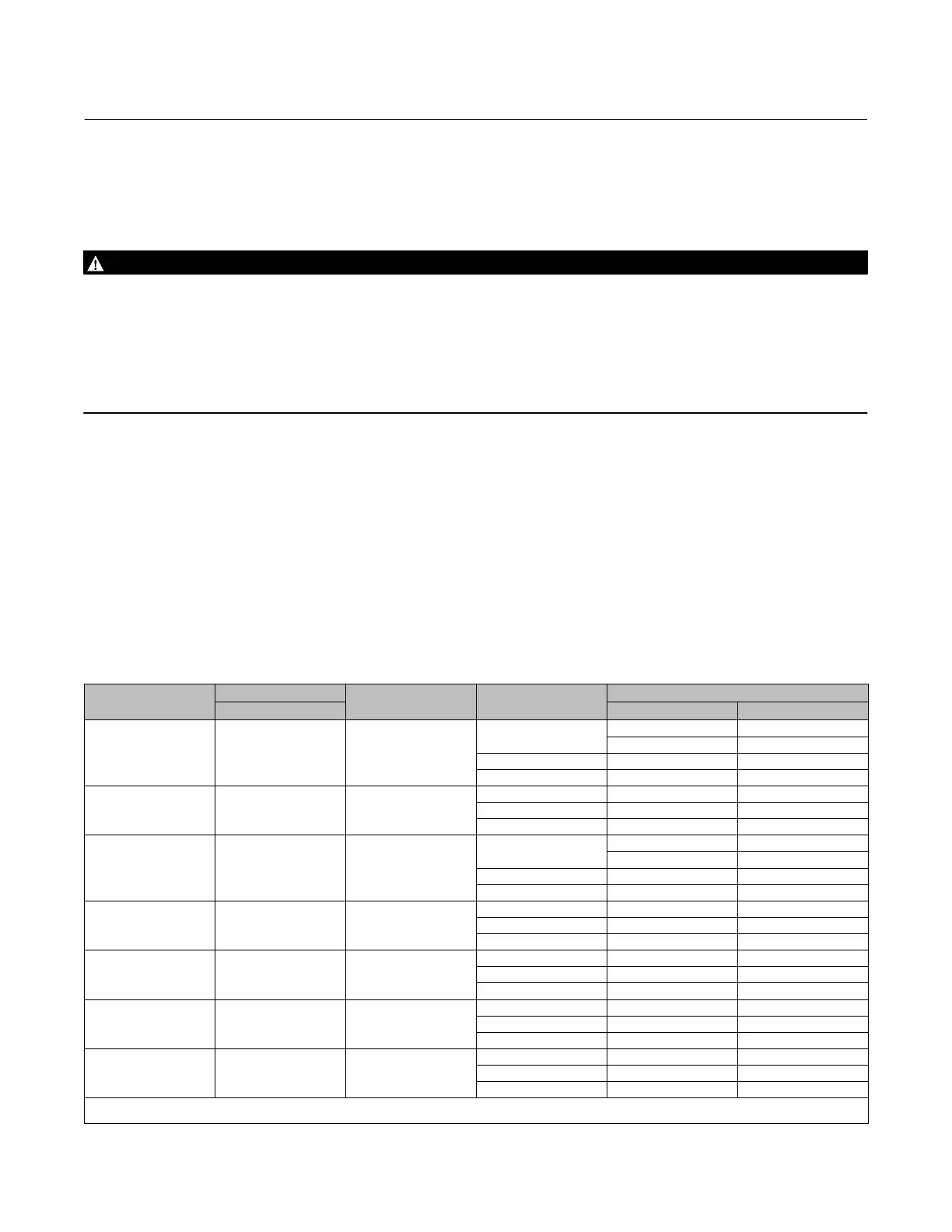

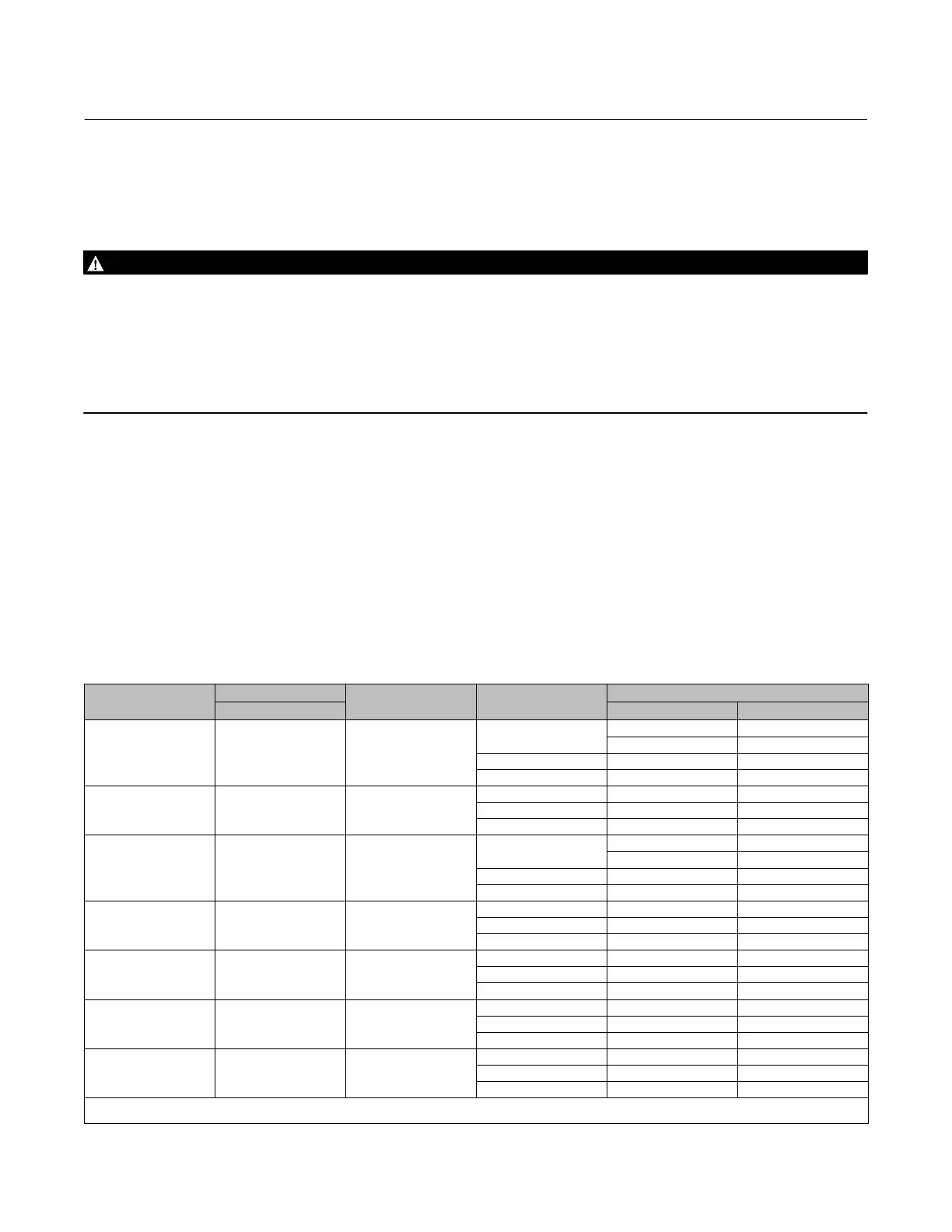

Table 2. Actuator Spring Configuration Based on Minimum Supply Pressure

(1)

ACTUATOR SIZE

TRAVEL

STEM MATERIAL

MINIMUM SUPPLY

PRESSURE

SPRING CONFIGURATION

mm Air‐to‐Open Air‐to‐Close

225 20

S20910, N05500

S31603

4 bar (58 psi)

A6 A3

A4

(2)

A4

(2)

3 bar (44 psi) A4 A3

2 bar (29 psi) A3 A2

225 20

S31803, N10675,

N06022

4 bar (58 psi) A6 A3

3 bar (44 psi) A4 A3

2 bar (29 psi) A3 A2

750 20

S20910, N05500

S31603

4 bar (58 psi)

B6 B4

B6

(2)

B6

(2)

3 bar (44 psi) B6 B4

2 bar (29 psi) B4 B4

750 20

S31803, N10675,

N06022

4 bar (58 psi) B4 B4

3 bar (44 psi) B4 B4

2 bar (29 psi) B4 B4

750 40

S20910, N05500

S31603

4 bar (58 psi) C12 C6

3 bar (44 psi) C8 C3

2 bar (29 psi) C4 C3

750 40

S31803, N10675,

N06022

4 bar (58 psi) C8 C6

3 bar (44 psi) C8 C3

2 bar (29 psi) C4 C3

1200 40 or 60

S20910, N05500

S31603

4 bar (58 psi) D15 D15

3 bar (44 psi) D15 D15

2 bar (29 psi) N/A N/A

1. Only applicable to actuators with spring information on the nameplate (see figure 2).

2. Only applicable to Cavitrol III constructions.

Loading...

Loading...