4-2

4.3 Configuring the Function Code Data Before Test Run

Configure the function codes listed below according to the motor ratings and your machinery design values. For

the motor ratings, check the ratings printed on the motor's nameplate. For your machinery design values, ask

system designers about them.

!

To set up function code, you need to use the keypad (option) or to access their data via communications

link. For details, refer to the FRENIC-Lift LM2A series Reference Manual.

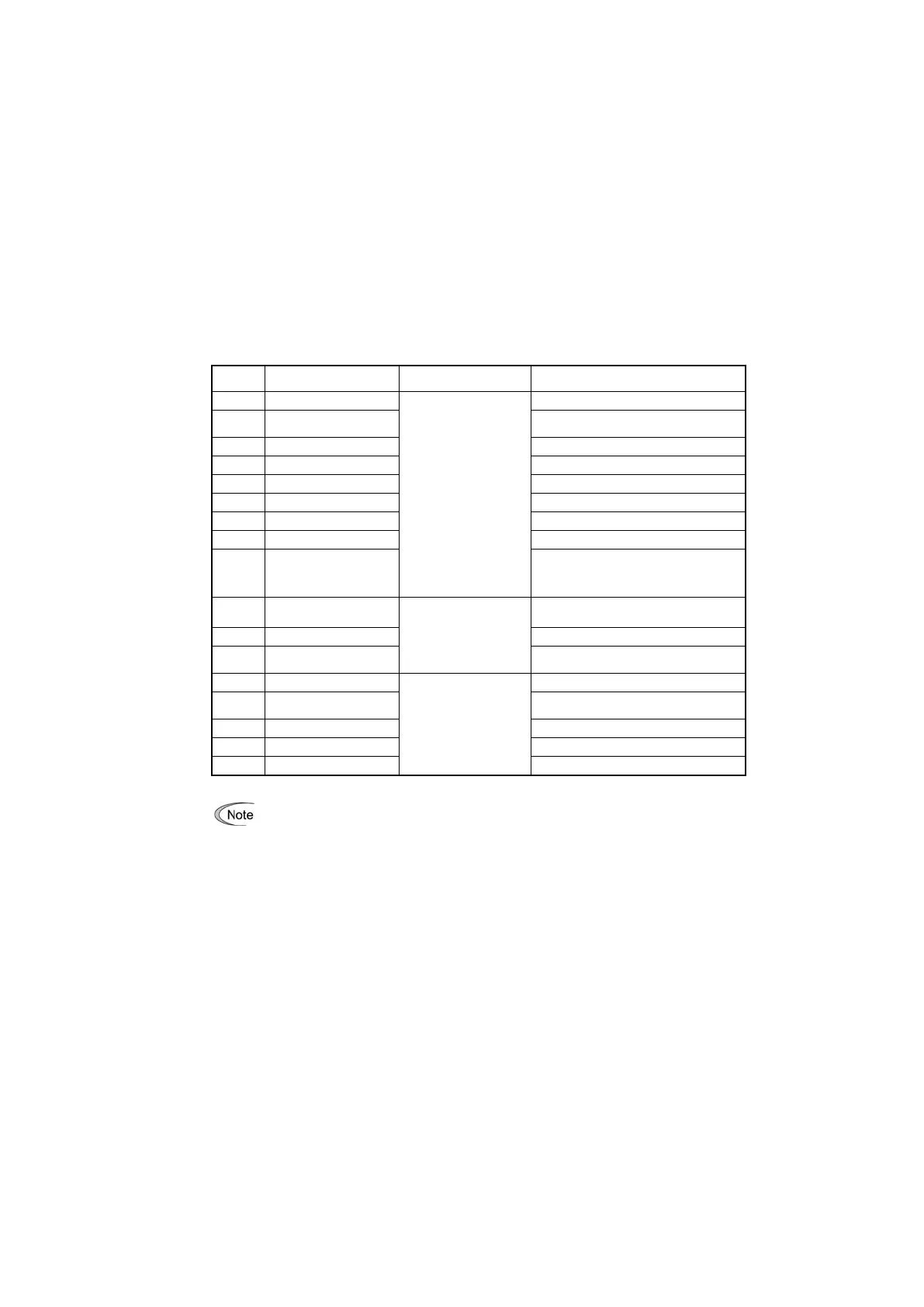

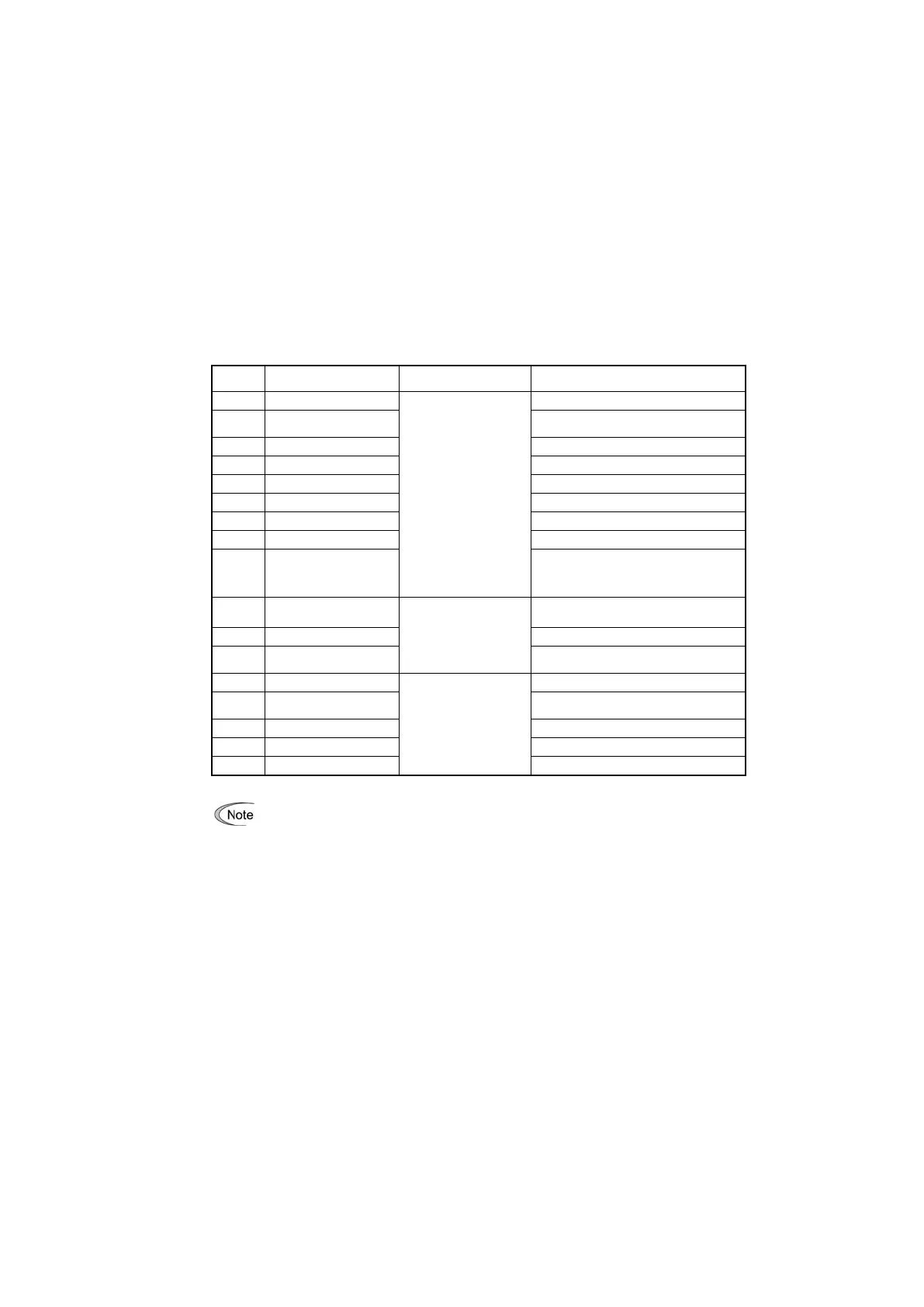

Table 4.1 Configuring Function Code Data

Motor ratings

(printed on the nameplate

of the motor)

Rated Voltage at Base

Speed

Nominal applied motor capacity.

Rated current of nominal applied motor.

No load current of the standard motor.

Primary resistance of the standard motor.

Leakage reactance of the standard motor.

0.00 (Hz)

*1

*1 The rated slip of the standard motor is

applied.

Pulse Encoder (Selection)

Depending on data sheet

of the pulse encoder.

0 : 12V/15V complementary, open collector

output circuit or 5V line driver.

Pulse Encoder (Resolution)

Magnetic pole position

Offset (Offset angle)

Motor Control Mode

Selection 1

0 : Vector control with PG

(Asynchronous motor)

0 : r/min (Speed data format)

Elevator Parameter (Speed)

1 : Motor rotates in CW(Clockwise) direction

*

Recommend to start the setting by the following order C21, P01, F03 and L31, etc.

・In any of the following cases, motor auto-tuning (P04) is necessary because the standard settings of

motor parameters for Fuji motors are not applicable:

- The motor to be driven is not a Fuji product or is a non-standard product.

- The cabling between the motor and the inverter is long.

- A reactor is inserted between the motor and inverter.

・To drive a synchronous motor, you need to tune the inverter for the offset angle of magnet pole before

running the motor. (L03)

・To drive a motor with encoder, an option card should be used which has to be ordered separately.

!

For details of motor tuning procedure refer to the FRENIC-Lift LM2A series Reference Manual.

Loading...

Loading...