8-6

8.6 Compliance with Functional Safety Standard

8.6.1 General

In FRENIC-Lift series of inverters, opening the hardware circuit between terminals [EN1]-[PLC] or between

terminals [EN2]-[PLC] stops the output transistor, coasting the motor to a stop (EN: Enable input). This is the

Safe Torque Off (STO) compliant with Functional Safety Standard EN/IEC 61800-5-2.

Using the Safe Torque Off (STO) function eliminates the need of external safety circuit breakers (i.e. magnetic

contactors) while conventional inverters need those breakers to set up the system compliant to Functional

Safety Standard.

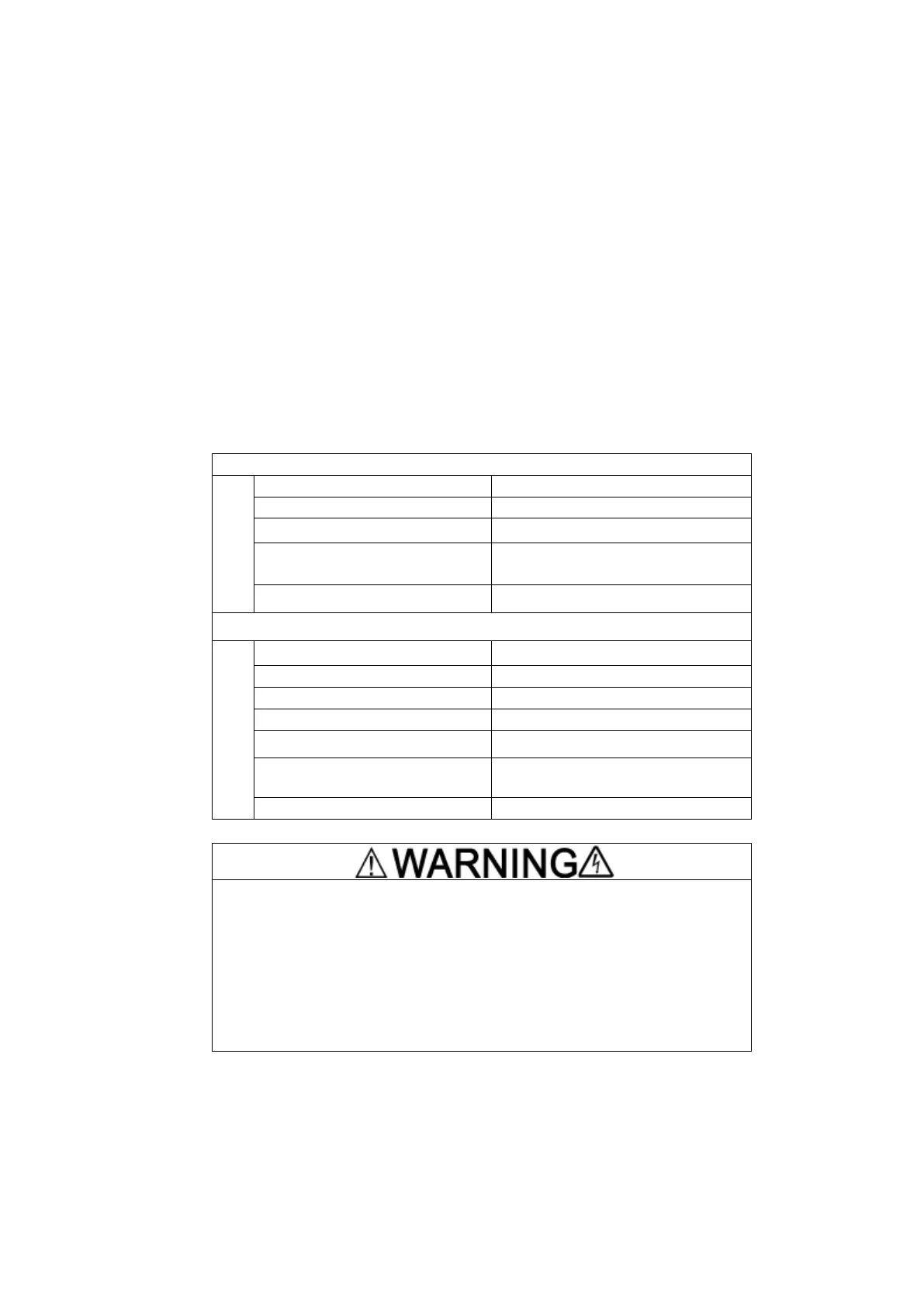

Table 8.3 shows the functional safety function performance.

Table 8.3 Functional Safety Function Performance

Response time

(Safety reaction time)

<= 50 ms

(Delay time from when either of terminals [EN1]

and [EN2] comes OFF to STO)

EN 61508-1 to -7

EN 61800-5-2

Safety Function (Stop function)

SIL (Safety integrity level)

HFT (Hardware Fault Tolerance)

SFF (Safe Failure Fraction)

< 1.0 ☓ 10

-3

(Average of Probability of Failure on Demand)

< 1.0 ☓ 10

-7

(Probability of a dangerous random hardware

failure per hour)

Proof test interval (Lift time)

• The output shutdown function of this inverter uses the Safe Torque Off (STO) function prescribed in IEC/EN

61800-5-2 so that it does not completely shut off the power supply to the motor electrically. Depending upon

applications, therefore, additional measures are necessary for safety of end-users, e.g., brake function that locks

the machinery and motor terminal protection that prevents possible electrical hazard(s).

• The output shutdown function does not completely shut off the power supply to the motor electrically. Before

starting wiring or maintenance jobs, therefore, be sure to disconnect the input power to the inverter and wait at

least five minutes.

• When a permanent magnet synchronous motor (PMSM) is coasting to a stop caused by the output shutdown

function, voltage is applied to its terminals. Before starting maintenance, inspection or wiring, therefore, be sure

to check that the PMSM is completely stopped.

An electric shock could occur.

Loading...

Loading...