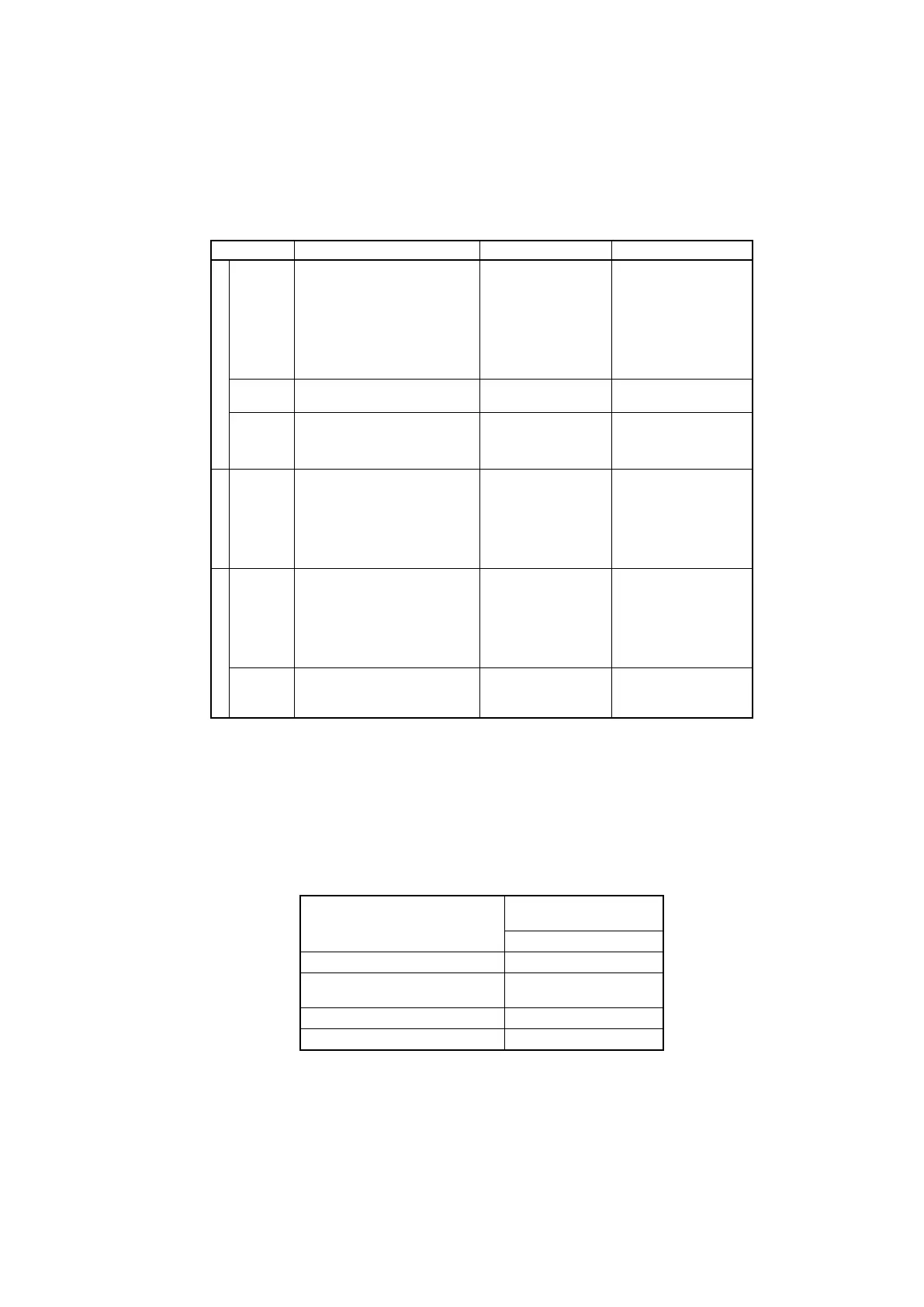

6-3

Table 6.1 List of Periodic Inspections (Continued)

1) Check for electrolyte leakage,

discoloration, cracks and swelling

of the casing.

2) Check that the safety valve is not

protruding remarkably.

3) Measure the capacitance if

necessary.

1), 2)

Visual inspection

3) Measure the discharge

time with capacitance

probe.

1), 2)

No abnormalities

3) The discharge time

should not be shorter

than the one specified by

the replacement manual.

Check for abnormal roaring noise

and odor.

Auditory, visual, and

olfactory inspection

Magnetic

contactor

and relay

1) Check for chatters during

operation.

2) Check that contact surface is not

rough.

1) Auditory inspection

2) Visual inspection

1) Check for loose screws and

connectors.

2) Check for odor and discoloration.

3) Check for cracks, breakage,

deformation and rust.

4) Check the capacitors for

electrolyte leaks and deformation.

1) Retighten.

2) Olfactory and visual

inspection

3), 4)

Visual inspection

1), 2), 3), 4)

No abnormalities

1) Check for abnormal noise and

excessive vibration.

2) Check for loose bolts.

3) Check for discoloration caused by

overheat.

1) Auditory and visual

inspection, or turn

manually (be sure to

turn the power OFF).

2) Retighten.

3) Visual inspection

1) Smooth rotation

2), 3)

No abnormalities

Check the heat sink, intake and

exhaust ports for clogging and

foreign materials.

Remove dust accumulating on the inverter with a vacuum cleaner. If the inverter is stained, wipe it off with a

chemically neutral cloth.

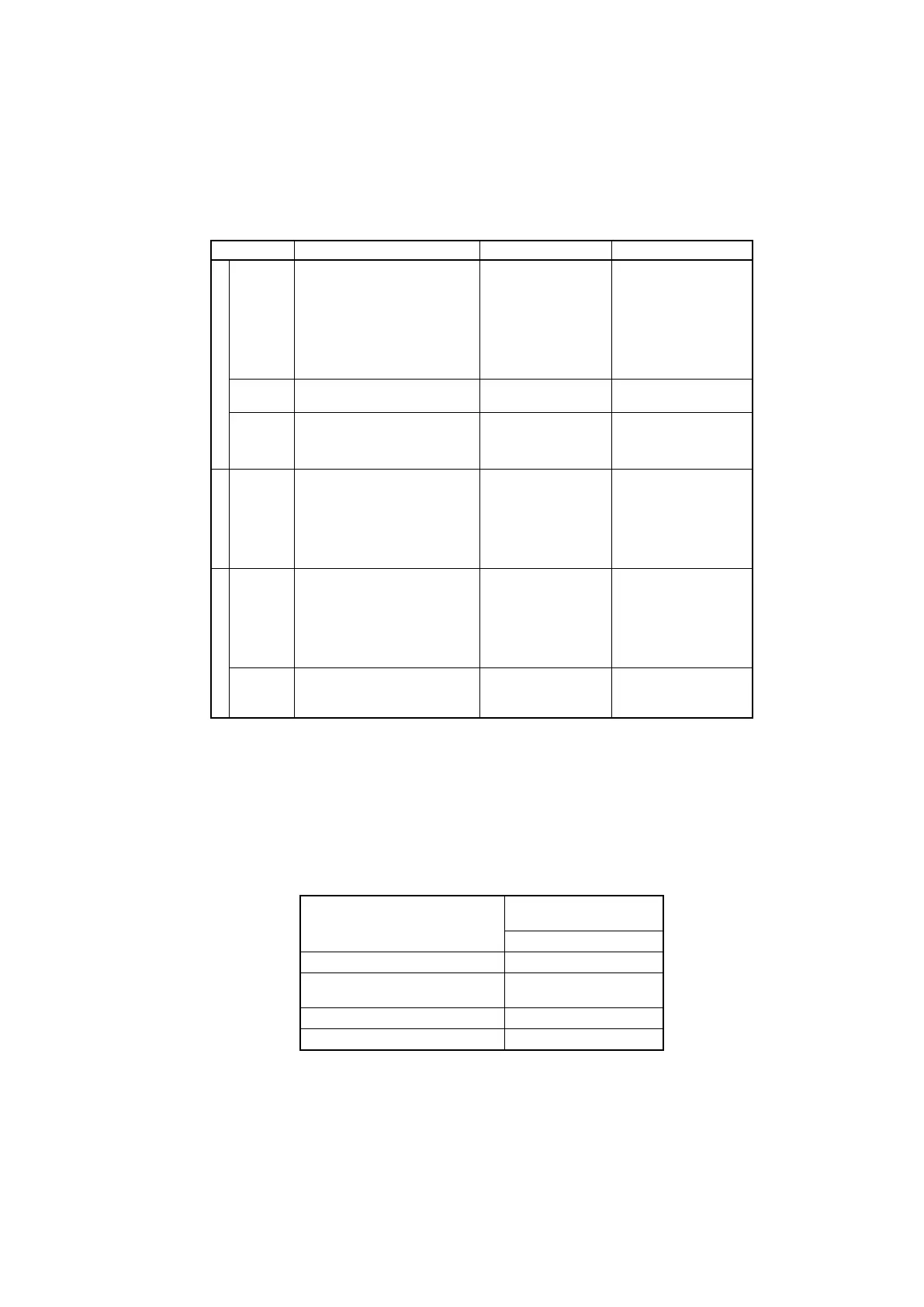

6.3 List of Periodic Replacement Parts

The inverter consists of many electronic parts including semiconductor devices. Table 6.2 lists replacement parts

that should be periodically replaced for preventive maintenance (use the lifetime judgment function as a guide).

These parts are likely to deteriorate with age due to their construction and properties, leading to the decreased

performance or failure of the inverter.

When the replacement is necessary, consult your Fuji Electric representative.

Table 6.2 Replacement Parts

Standard replacement intervals

(See Notes below.)

Electrolytic capacitors on printed circuit

boards

Relay output of control circuit terminals

Loading...

Loading...