35

10 Twin Flue - Length, Preparation and Installation

10.15 Twin ue

The twin ue system is available as an option when the top

horizontal or vertical ue system is not appropriate.

The system can provide an independent horizontal air inlet

and ue outlet, horizontal air inlet and vertical ue outlet or

vertical air inlet and ue outlet via a concentric terminal.

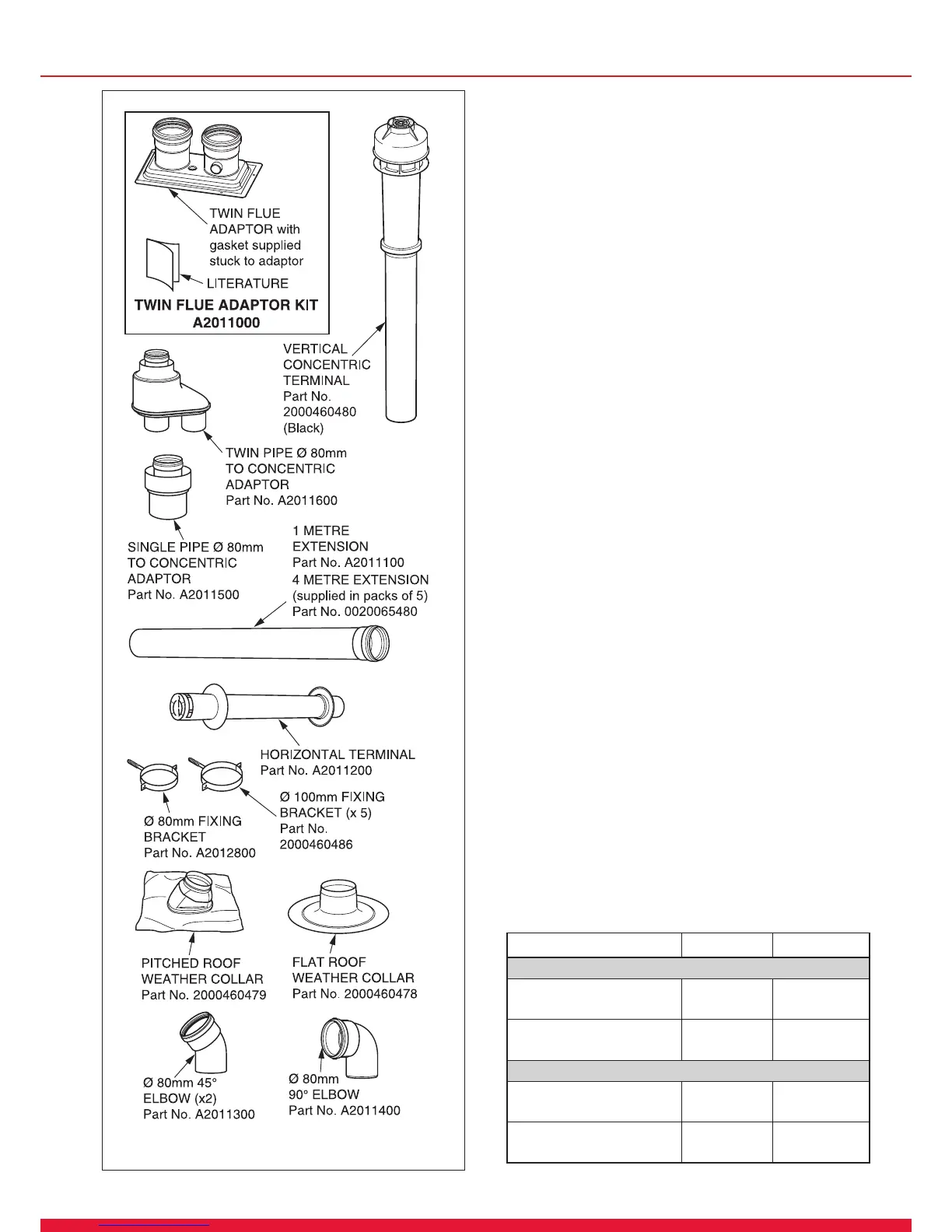

The system is made up from accessories, see diagram 10.30.

NOTE: The air and ue outlets do not have to be equal

lengths. 2x45° bends can replace 1x90° bend if necessary.

The maximum permitted combined (air inlet + ue outlet) ue

length is 20 metres plus terminal assemblies. For each 90°

or

45°

x 2 bends tted, the maximum ue length must be reduced

by 1 metre, see diagram 10.29.

NOTE: When using 90° bends any horizontal run should be

inclined by a minimum of 44mm/metre (2.5°) towards the

boiler to facilitate condense removal.

Alternatively use 45° bends to avoid horizontal runs in the ue

pipe.

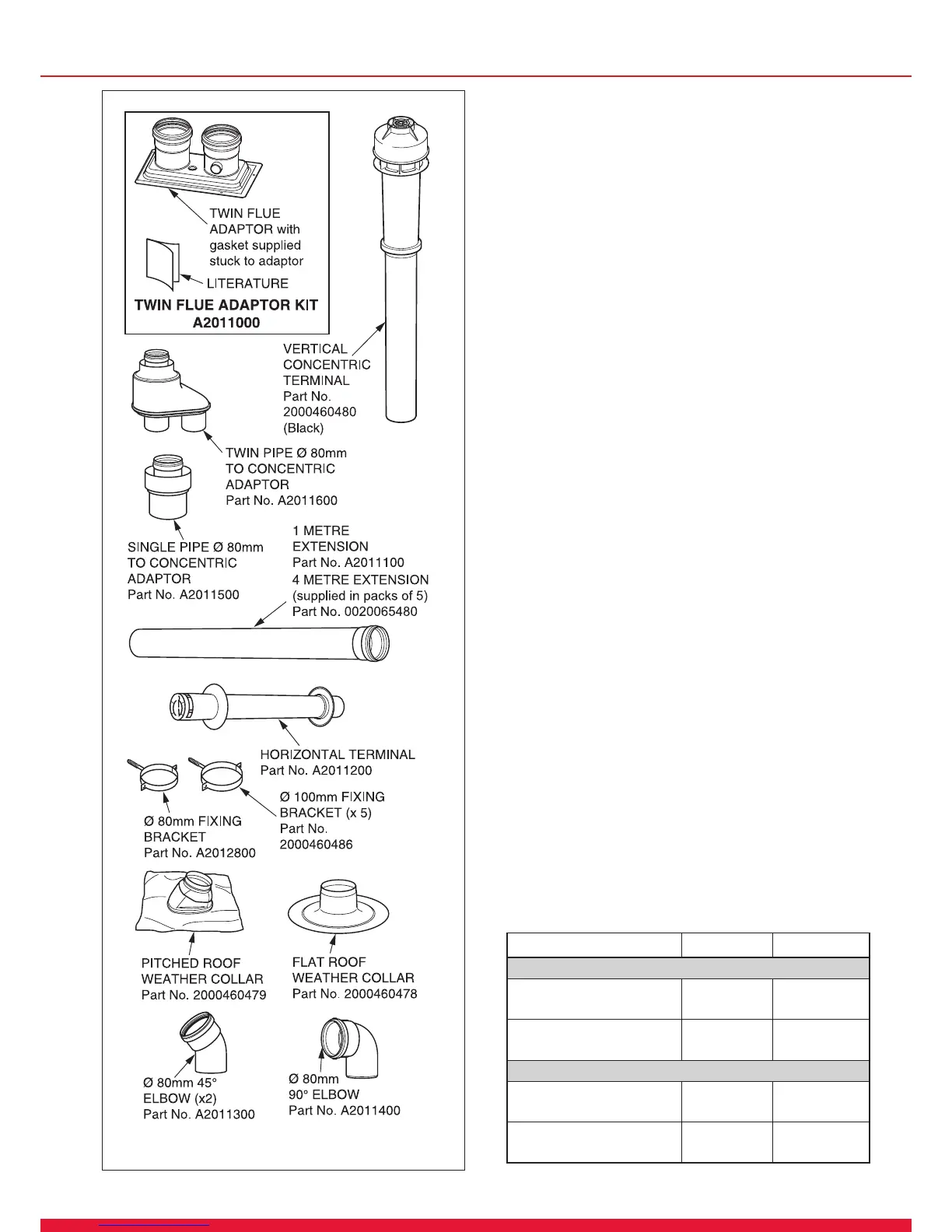

Multiple Boiler Chimney Flue Length

The ue length must be calculated and installed according to

the relevant standards EN 13384-1 and 2 (C43 ue systems

only) with reference to the table below and the manufacturers

instructions supplied.

The appliance maximum ue length must be included when

calculating the overall design of the ue system.

Terminal Position

The clearances for a ue outlet are given in the "Flue Location

and Ventilation" section.

In addition the horizontal air inlet must not be closer than 300

mm from a ue outlet on the same wall or 1200mm from an

opposing ue outlet.

Installation Details

The parts available for a twin ue system installation are

shown in diagram 10.30.

Diagram 10.30

14869

MODEL 18sx 30sx

Exhaust mass rate (g/s)

At Min Thermal

Load (40C°/30°C)

4.26 4.26

At Max Thermal

Load (80C°/60°C)

8.24 13.95

Exhaust temperature (ºC)

At Min Thermal

Load (40C°/30°C)

33.2 33.2

At Max Thermal

Load (80C°/60°C)

63.0 87.4

Loading...

Loading...