Repair

Change Pump Lu

bricant

Check the condition of the ISO pump lubricant daily.

Change the lubricant if it becomes a gel, its color

darkens, or it becomes diluted with isocyanate.

Gel formatio

n is due to moisture absorption by the

pump lubrica

nt. The interval between changes

depends on th

e environment in which the equipment

is operatin

g. The pump lubrication system minimizes

exposure to

moisture, but some contamination is still

possible.

Lubricant discoloration is due to continual seepage of

small amounts of isocyanate past the pump packings

during operation. If the packings are operating

properly, lubricant replacement due to discoloration

should not be necessary more often than every 3 or

4weeks.

To change pump lubricant:

1. Follow Pr

essure Relief Procedure, page 49.

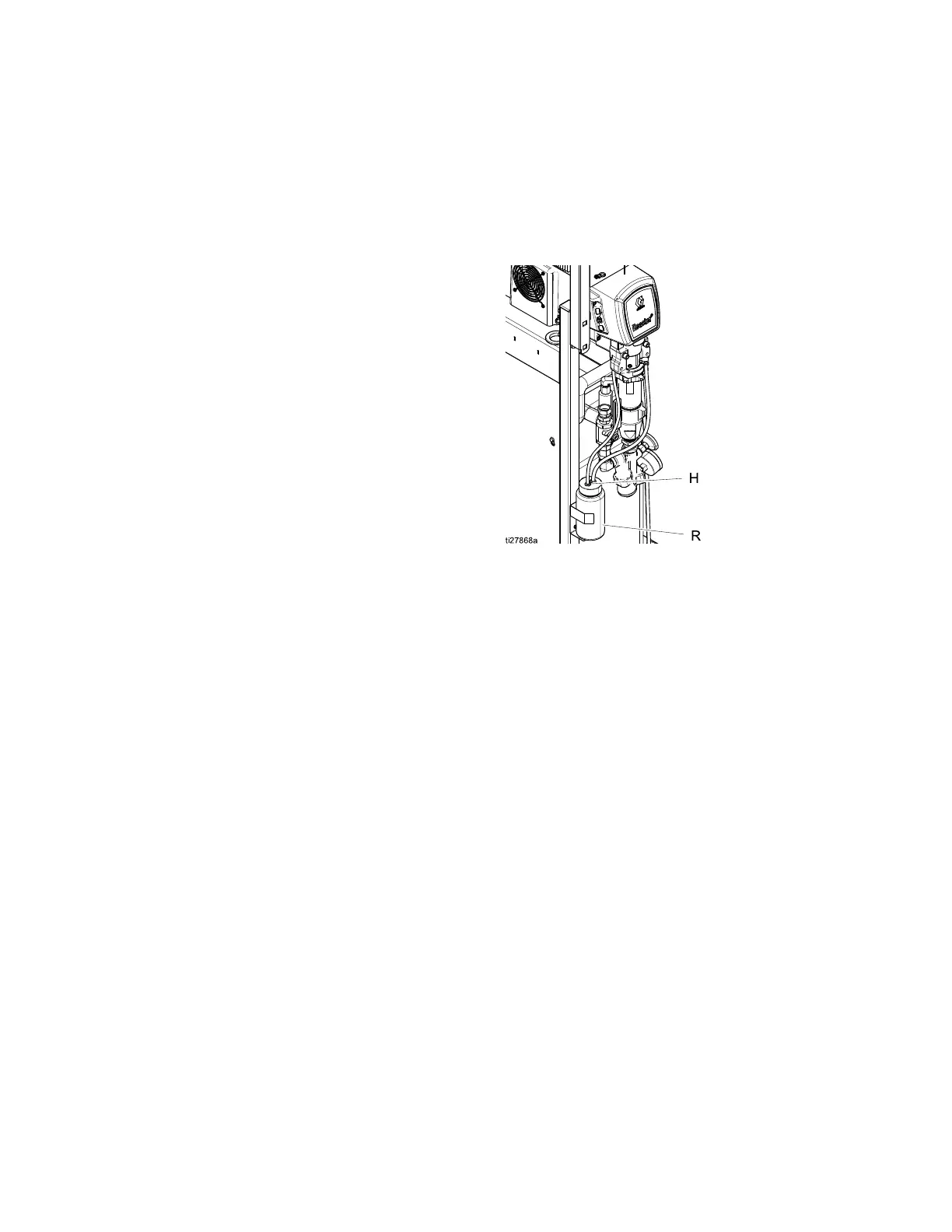

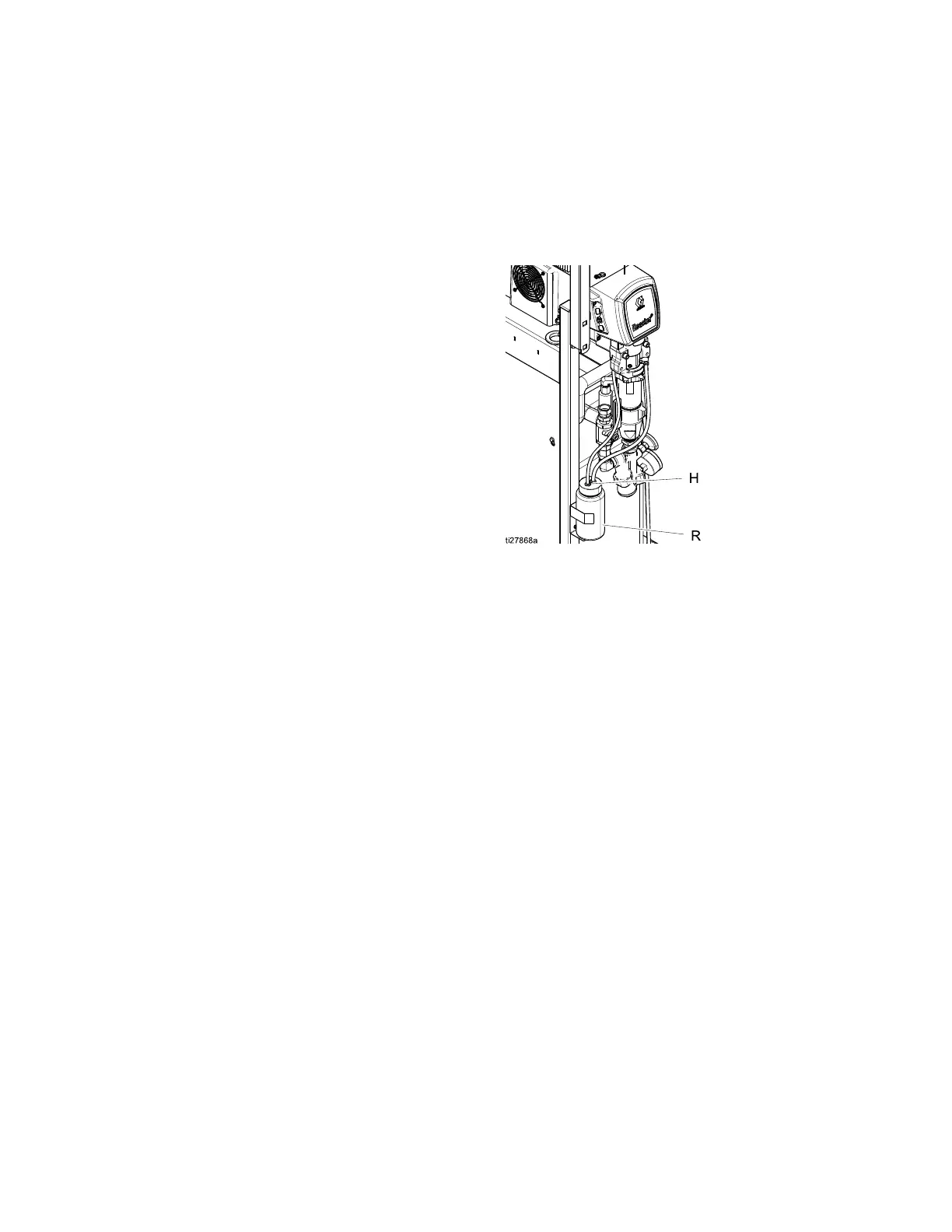

2. Lift the

lubricant reservoir (R) out of the bracket

and remo

ve the container from the cap. Holding

the cap o

ver a suitable container, remove the

check va

lve and allow the lubricant to drain.

Reattac

h the check valve to the inlet hose.

3. Drain t

he reservoir and flush it with clean

lubric

ant.

4. When th

e reservoir is flushed clean, fill with fresh

lubric

ant.

5. Thread the reservoir onto the cap assembly and

place it in the bracket.

6. Manually prime the ISO pump. Plug the small

vent hole (H) between the tube grommets while

squeezing the bottle to force the lubricant up the

feed tube. Repeat until the fluid level reaches the

ISOpumptoforcetheairout.

7. Verify that the ISO pump is operating correctly

by feeling the pulsation in the return tube during

normal proportioner pump operation.

8. Ensure the vent hole stays open.

54 333024N

Loading...

Loading...