1.3 Product Features

1.3.1 General

It‘s a kind of integrated DC inverter unit that comprises cooling, heating and water heating functions,

and up to 5.0 energy efficiency. It adopts R32 refrigerant and two-stage compressor. For heating,

ambient temperature range is -25~35

℃

while the leaving water temperature range is 25~60

℃

.

The Versati

Ⅲ

unit is designed specially for the European market where there is a demand for

high-temperature water. Thanks to the dual-stage compression and enthalpy gain through gas injection,

the heating energy efficiency at low temperature will rise up greatly with the leaving water temperature

up to 60°C. The whole series of products strictly comply with EN14511,EUROVENT energy efficiency

Class A and SCOP class A+++(35

℃

), SCOP class A++(55

℃

) with EN14825. Their COP can reach up to

5.0. This unit can realize space heating and sanitary hot water supply through terminal units, like the fan

coil unit, floor coil and radiator. Environment-friendly refrigerant R32 is adopted for the unit, with ODP of

0 and quite low GWP (=675). Besides, the adopted heat pump technologies will reduce consumption of

coal and other energy source and lower greatly CO2 emission. Ranged from 4.0kW~16kW, it is widely

applicable to small and medium-sized apartment, large-sized villa etc.

1.3.2 Features

Wide Operation Range

Heating: -25~35°C; Cooling: 10~48°C; Water Heating: -25~45°C

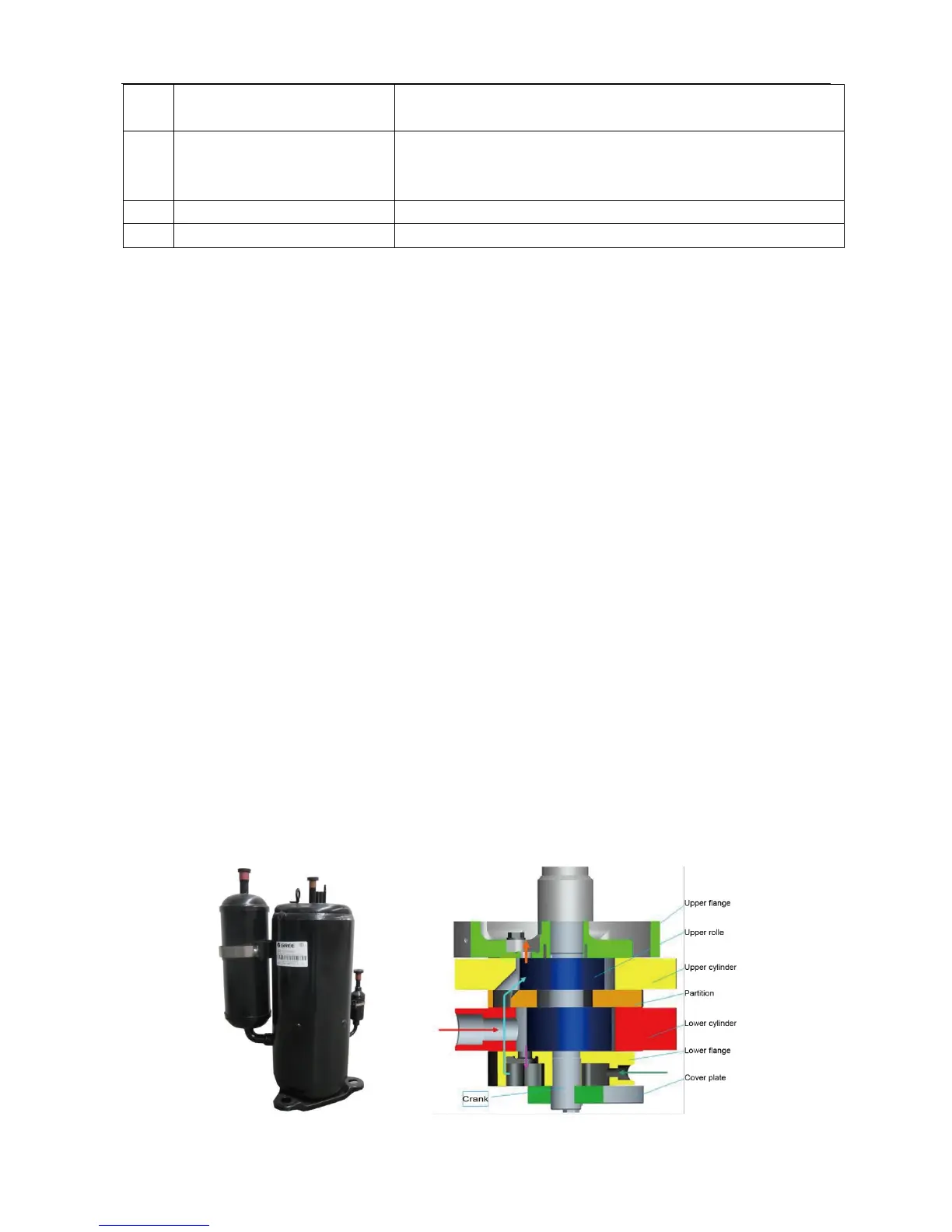

Unique Low-Temp Hi-heat Dual-stage Compressor

1. Under low-temperature conditions, compared with the conventional compressor, the dual-stage

low-temp hi-heat compressor will generate less loss of heat capacity and get higher energy efficiency.

2. Floodback, high discharge temperature and other problems can be completely avoided under

low-temp conditions and the compressor‘s reliability will be enhanced greatly.

3. Dual-stage compression, dual-stage throttling and intermediate enthalpy adding through gas

injection will raise the leaving water temperature and improve the control accuracy.

High-efficiency Component(Inverter pump, Inverter fan, Plate heat exchanger)

Loading...

Loading...