Maintenance

Technical Catalogue

TCGB0051 rev 0 - 09/2009

68

Components

The unit should be periodically inspected according to the same items as those described in

the paragraph titled

“Test Running“. In order to ensure dependable performance and long life operation, the

following additional items should be given for particular attention.

11.1. Components

¡ Compressor

The semi-hermetic screw compressor requires periodic maintenance, including

replacement of parts. See the HITACHI Service Handbook for Screw Compressors, for

details.

¡ Electrical Equipment

Always pay careful attention to working voltage, amperage and phase balance. Check for

faulty contact caused by loosened terminal connections, oxidised contacts, foreign matter,

and others.

¡ Control and Protective Devices

Do not readjust the settings in the eld unless the setting is maintained at the point other

than the point listed in the table on chapter 8..

11.2. Lubrication

¡ Compressor

The compressors are charged at the factory with the correct oil listed in “Component

Data” and the compressor nameplate. It is not necessary to add oil, if the refrigerant cycle

remains sealed.

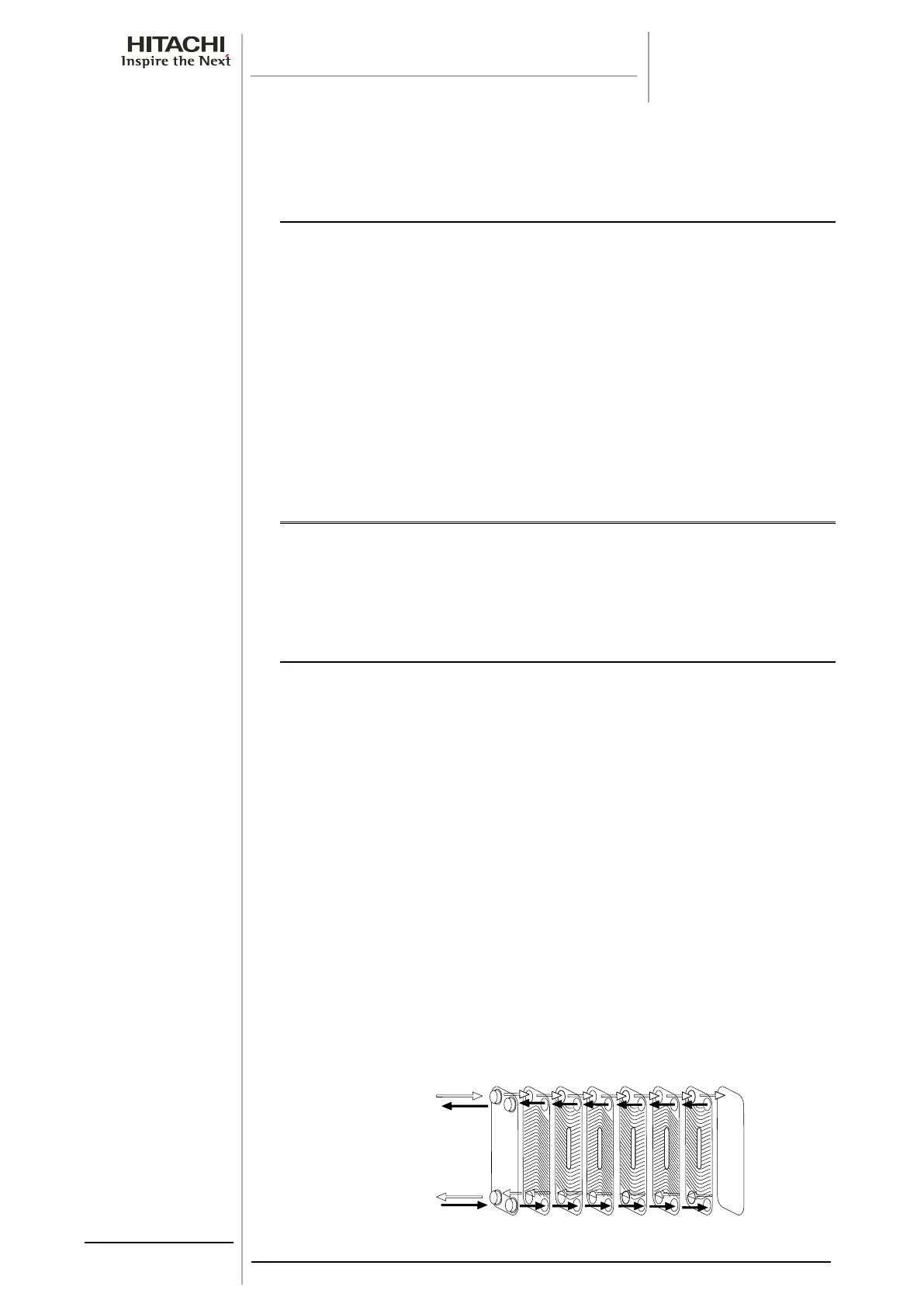

11.3. Deposits

Lime and other minerals in the condenser water or chilled water tend to deposit on

inside surfaces of plates over a long period of operation. As deposits of these minerals

increase, excessive high discharge pressure or lower operation pressure are detected,

indicating evidence of deposits on the condenser or the water cooler. The gure in page

31 indicates the range where cleaning is required.

(Condenser: In the case of water-cooled type)

CAUTION:

- Cleaning of plate type heat exchangers shall be performed by specialists. Please contact your

contractor or dealer of HITACHI.

- Clean the water strainer lter periodically according to its clogging degree. If not cleaned

periodically, the water strainer will be broken due to an excessive pressure to the strainer

screen.

WARNING:

- This product is equipped with plate type heat exchangers. In the plate type heat exchanger,

water ows through a narrow space between plates. Therefore, there is a possibility that freezing

may occur if foreign particles or dusts are clogged. In order to avoid this clogging, provide a

20 mesh water strainer at the inlef of the chilled water piping near the product. If clogging in

the plate type heat exchanger occurs seriously, this will cause insufcient cooling performance

or local freezing in the plate type heat exchanger. It is strongly recommended that the heat

exchanger be cleaned at the same time when the lter is cleaned.

- Pay attention to the following caution and normal cleaning method. For details, contact your

Hitachi installer.

WARNING:

If a re accidentally

occurs, turn OFF the

main switch and use an

extinguisher for an oil

re and an electric re.

Do not operate the unit

near ammable gases

such lacquer, paint oil,

etc. to avoid a re or an

explosion.

Turn OFF the main

switch when electrical

box covers are

removed for setting the

temperature. Do not

operate the unit without

xing panels.

DANGER:

Switch OFF main

interruptor (M.I.) for any

work inside electrical

box.

CAUTION:

Perform periodical

maintenance

according to the

“INSTRUCTIONS“ to

maintain the unit in a

good condition.

Do not touch the parts

at the discharge gas

side by hand, since the

pipes at the discharge

side are heated by

refrigerant and the

temperature becomes

higher than 100 °C.

Do not utilize this unit

for cooling or heating of

drinking water or food.

Comply with local codes

and regulations.

Turn OFF all the main

switches if refrigerant

leakage or chilled / hot

water leakage occurs.

Also, if the unit can

not be stopped by the

control switch, turn

OFF all the switches for

power source.

Refrigerant

Water

Loading...

Loading...