BF15D-BF20D

2.

FRICTION

ADJUSTING

LEVER

a.

DISASSEMBLY

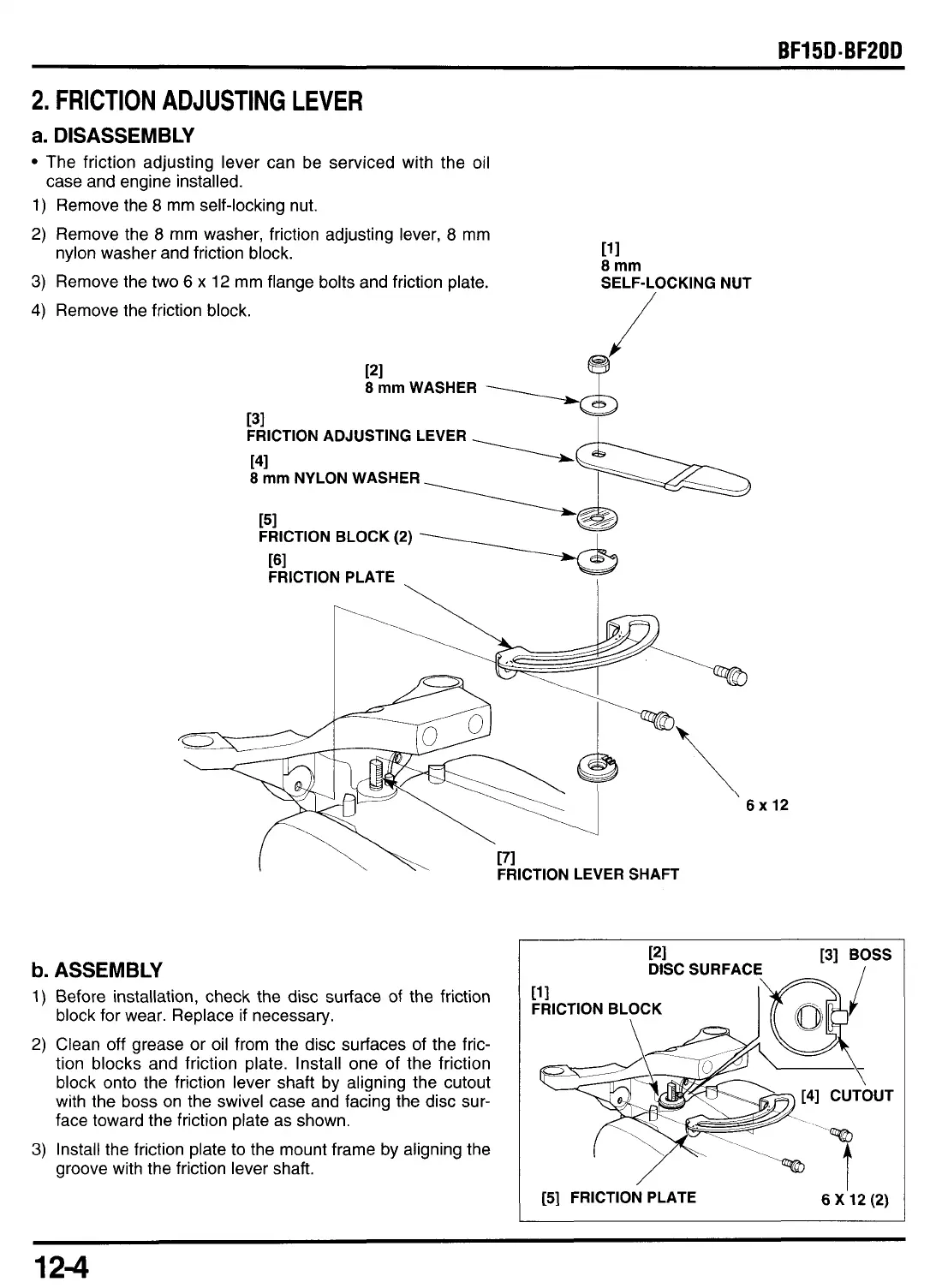

The friction adjusting lever can be serviced with the oil

1) Remove the

8

mm self-locking nut.

2) Remove the

8

mm washer, friction adjusting lever,

8

mm

nylon washer and friction block.

3)

Remove the two

6

x

12 mm flange bolts and friction plate.

case and engine installed.

111

8

mm

SELF-LOCKING NUT

4)

Remove the friction block.

121

8

mm

WASHER

r3i

I

~RICTION

ADJUSTING

LEVER

141

8

mm

NYLON WASHER

151

FRICTION BLOCK (2)

[GI

FRICTION PLATE

.

FRICTION LEVER SHAFT

b.

ASSEMBLY

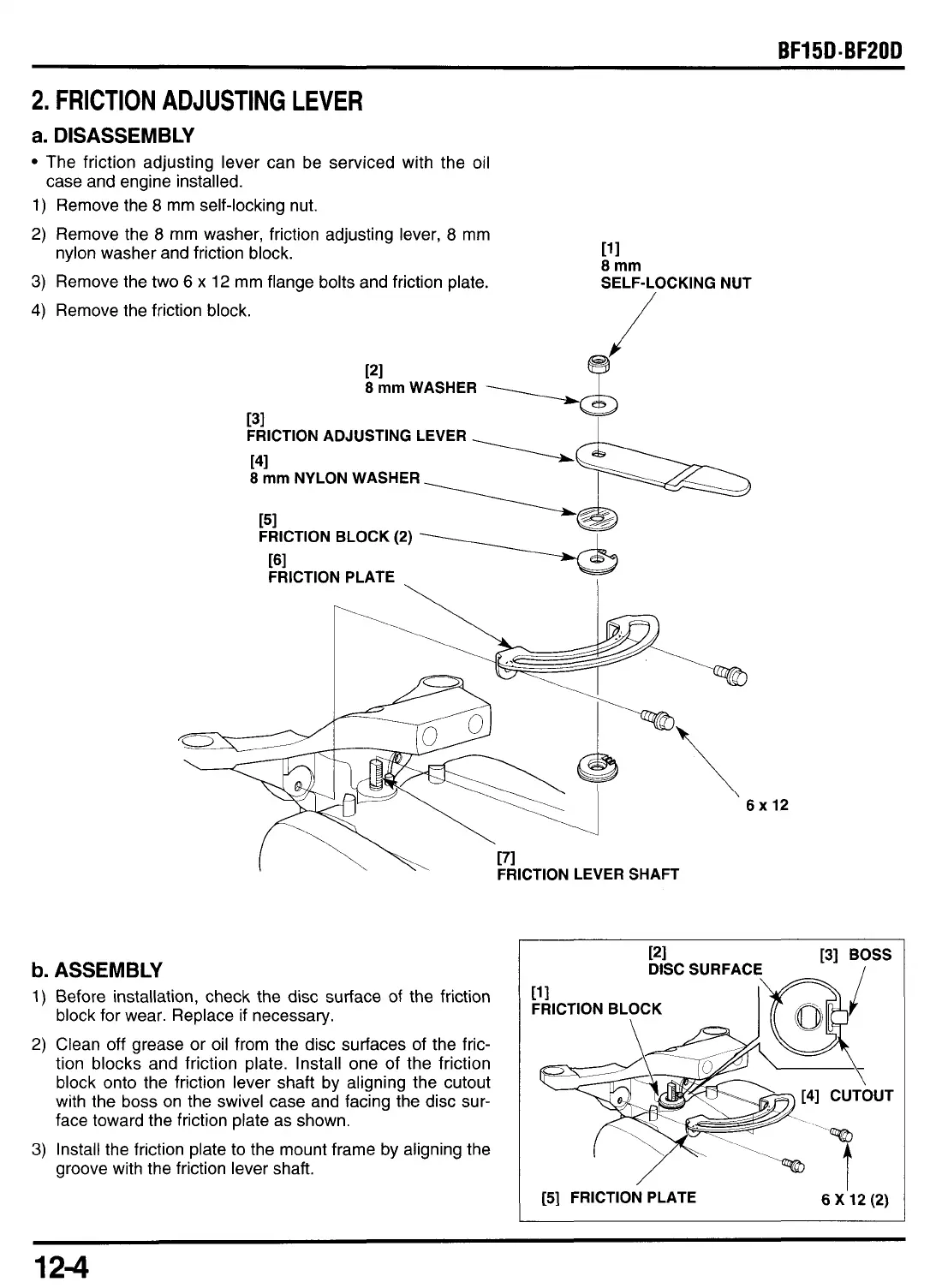

1)

Before installation, check the disc surface of the friction

block for wear. Replace

if

necessary.

2) Clean off grease or oil from the disc surfaces of the fric-

tion blocks and friction plate. Install one

of

the friction

block onto the friction lever shaft by aligning the cutout

with the boss on the swivel case and facing the disc sur-

face toward the friction plate as shown.

3)

Install the friction plate

to

the mount frame by aligning the

groove with the friction lever shaft.

x

12

[5] FRICTION PLATE

6

X'l2

(2)

12-4

Loading...

Loading...